Five ways to unscrew a bolt with torn edges

The edges of the bolts become rounded over time, which especially happens with soured and rusted bolts that cannot be unscrewed. Trying to do this, people often additionally turn the edges themselves, rendering not only the bolt heads unusable, but also the keys they used to unscrew them.

There are several ways to unscrew almost any bolt, regardless of the degree of rust and the condition of the edges. Using these methods, you can unscrew any bolts, even those whose heads have been torn out, but a piece of the bolt remains in the thread. We’ll talk about these methods today.

What you may need to unscrew any bolt or nut:

If you have all this, you can unscrew almost everything!

If traditional methods do not help, then it’s time to purchase a special tool with which you can unscrew anything!

1. Special extractor heads. The internal parts of these heads have spirally twisted grooves, and the hole itself is cone-shaped. In order to unscrew a bolt using such an extractor, you need to drive a socket wrench onto the head of the bolt and turn it! The taper allows you to clamp the bolt head, and the spiral grooves pick up the edges and unscrew the bolt. Then the bolt itself will have to be knocked out of the key.

They can also have a different shape.

2. In second place are ring wrenches with special shaped grooves.The principle of operation of such a key coincides with the operation of extractor heads.

3. In third place is an adjustable wrench, which also easily unscrews bolts and nuts. A distinctive feature of such a key is its high clamping force due to the lever rule, as well as a wide range of sizes, since the key is sliding.

4. Impact methods. Here you can use a classic set of a hammer and chisel and special screwdrivers with a solid shaft adapted for impact.

First, a groove is knocked out with a chisel or screwdriver, and then the bolt is unscrewed by striking this groove. The method can be simplified if you use a special impact tool. When you hit the back of such a hammer screwdriver, its head produces a rotational impact on the bolt. You can also use a wrench to simplify the work, and you can also weld a nut to the damaged bolt head if there is open access to the unit being repaired.

The impact screwdriver also proved to be no worse.

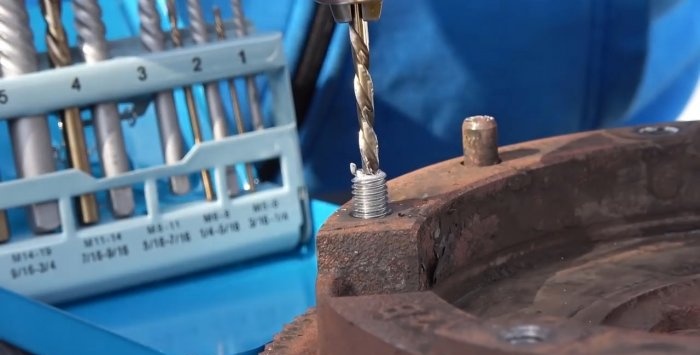

5. The fifth method is useful for unscrewing the remaining bolts remaining in the threads after the bolt head has been completely torn out. For these purposes, extractors are sold that are driven into the hole. It is enough to drill a small hole into which the extractor is driven.

You can also use a left-handed drill.

Now it is enough to take any key to unscrew the extractor along with the rest of the bolt.

If the bolt is not broken, but its head is almost completely destroyed, then, if available, you can use welding by welding the nut on top.

Using these methods, you can unscrew almost any bolt, its fragment or nut that seems impossible to unscrew! But when working with any of these tools, you need to follow safety rules, working in gloves, glasses and overalls.

There are several ways to unscrew almost any bolt, regardless of the degree of rust and the condition of the edges. Using these methods, you can unscrew any bolts, even those whose heads have been torn out, but a piece of the bolt remains in the thread. We’ll talk about these methods today.

Will need

What you may need to unscrew any bolt or nut:

- a set of keys of different design solutions;

- liquid key or wd-40;

- drill with drills;

- extractors

- impact screwdriver;

- impact wrench;

- electric welding machine;

If you have all this, you can unscrew almost everything!

Traditional methods:

- Regular keys. If your key turns, try replacing it.Instead of wrenches, you can use box wrenches. Among the spanners there are also options - multi-sided wrenches and hexagonal ones. You can also try tube heads, which can be used with variable-angle handles to get into awkward places. Depending on the quality of the wrench and the condition of the bolt, you can experiment to see which wrench will remove the problem nut or bolt.

- Liquid key. In auto parts stores, this product can be called differently, but most often it is WD-40, popularly called “VeDe-shka” or “liquid key”. By shaking the can and pointing the spray nozzle at the bolt, we wet it. You need to wait a few minutes and then try to unscrew the bolt. This method is suitable for rusted bolts.

- Warm up It is necessary to warm up a bolt or nut in cases where it is so rusty that even a liquid wrench cannot handle it and the auxiliary lever does not help. You can warm it up using a regular gas burner.

If traditional methods do not help, then it’s time to purchase a special tool with which you can unscrew anything!

5 best ways to unscrew a bolt or nut!

1. Special extractor heads. The internal parts of these heads have spirally twisted grooves, and the hole itself is cone-shaped. In order to unscrew a bolt using such an extractor, you need to drive a socket wrench onto the head of the bolt and turn it! The taper allows you to clamp the bolt head, and the spiral grooves pick up the edges and unscrew the bolt. Then the bolt itself will have to be knocked out of the key.

They can also have a different shape.

2. In second place are ring wrenches with special shaped grooves.The principle of operation of such a key coincides with the operation of extractor heads.

3. In third place is an adjustable wrench, which also easily unscrews bolts and nuts. A distinctive feature of such a key is its high clamping force due to the lever rule, as well as a wide range of sizes, since the key is sliding.

4. Impact methods. Here you can use a classic set of a hammer and chisel and special screwdrivers with a solid shaft adapted for impact.

First, a groove is knocked out with a chisel or screwdriver, and then the bolt is unscrewed by striking this groove. The method can be simplified if you use a special impact tool. When you hit the back of such a hammer screwdriver, its head produces a rotational impact on the bolt. You can also use a wrench to simplify the work, and you can also weld a nut to the damaged bolt head if there is open access to the unit being repaired.

The impact screwdriver also proved to be no worse.

5. The fifth method is useful for unscrewing the remaining bolts remaining in the threads after the bolt head has been completely torn out. For these purposes, extractors are sold that are driven into the hole. It is enough to drill a small hole into which the extractor is driven.

You can also use a left-handed drill.

Now it is enough to take any key to unscrew the extractor along with the rest of the bolt.

If the bolt is not broken, but its head is almost completely destroyed, then, if available, you can use welding by welding the nut on top.

Conclusion

Using these methods, you can unscrew almost any bolt, its fragment or nut that seems impossible to unscrew! But when working with any of these tools, you need to follow safety rules, working in gloves, glasses and overalls.

Watch the video

Similar master classes

Particularly interesting

Comments (2)