DIY laminate installation

Laminate allows you to quickly and effortlessly create a high-quality floor covering in any room. The shape of the components is made in such a way that even a person who does not have professional knowledge can easily install the decorative floor covering. The ease of cutting and combining sheets allows you to quickly lay out a whole canvas, even in rooms with a complex layout. It is necessary to follow the technology so that laying the laminate with your own hands is done efficiently, and the result is a beautiful floor.

The initial stage is mandatory surface preparation. It must be cleaned of dirt and dust. The best way is to clean it with a special construction vacuum cleaner. After this, the floor is primed, regardless of the type of flooring (wooden or concrete). If it is made of wood, then in addition to being treated with a primer mixture, it is subjected to an antiseptic solution.

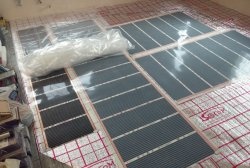

The concrete base is covered with a waterproofing film. It will provide protection not only from moisture, but will also serve as a heat-insulating material.The polyethylene sheet is laid overlapping, and all seams are taped with construction tape.

The next layer will be foamed cellophane as a soundproofing component. Since laying the laminate with your own hands is done from the window, the lining is done only in the area where the flooring is formed. This will allow you to get a seamless coating and ensure cleanliness when doing the work yourself. All subsequent parts of the substrate are laid end to end with the previous ones and secured together with tape. There are types of coatings that already contain a soundproofing layer in their structure. In this case, there is no need for a foam cellophane backing.

Installation of the first lamella begins in the corner of the room near the window. In this case, wedges are installed between it and the wall. Subsequent parts are placed end-to-end in whole strips. It is important to observe the correct connection of all components of the structure.

At the ends of the lamellas there are special grooves into which adjacent elements are installed. If you need to fit an incomplete sheet, you can use a segment. To do this, the whole strip needs to be turned with its short end towards the wall and mark the cut line. The required gap between the coating and the wall must be maintained. Based on the measurements taken, the required length is cut and inserted into the overall structure.

The second and subsequent rows begin with the remaining cut lamella, but only if it is at least 30 cm in length. In all other cases, a cut is made from a new sheet. All elements of this row are assembled without a locking connection with the previous one. Only after the second row is completely joined, the entire structure snaps into place. It is not recommended to use a hammer to tightly adhere the elements.However, if the need arises, you can place a wooden block in places where there is a loose connection and secure the locks with light blows.

Following the basic recommendations, you need to fill all the space on the floor. Only areas with uneven surfaces or containing communication elements need special attention.

By following all the above tips, laying laminate flooring with your own hands will not be a painful ordeal for you.

DIY laminate installation

The initial stage is mandatory surface preparation. It must be cleaned of dirt and dust. The best way is to clean it with a special construction vacuum cleaner. After this, the floor is primed, regardless of the type of flooring (wooden or concrete). If it is made of wood, then in addition to being treated with a primer mixture, it is subjected to an antiseptic solution.

The concrete base is covered with a waterproofing film. It will provide protection not only from moisture, but will also serve as a heat-insulating material.The polyethylene sheet is laid overlapping, and all seams are taped with construction tape.

The next layer will be foamed cellophane as a soundproofing component. Since laying the laminate with your own hands is done from the window, the lining is done only in the area where the flooring is formed. This will allow you to get a seamless coating and ensure cleanliness when doing the work yourself. All subsequent parts of the substrate are laid end to end with the previous ones and secured together with tape. There are types of coatings that already contain a soundproofing layer in their structure. In this case, there is no need for a foam cellophane backing.

Installation of the first lamella begins in the corner of the room near the window. In this case, wedges are installed between it and the wall. Subsequent parts are placed end-to-end in whole strips. It is important to observe the correct connection of all components of the structure.

At the ends of the lamellas there are special grooves into which adjacent elements are installed. If you need to fit an incomplete sheet, you can use a segment. To do this, the whole strip needs to be turned with its short end towards the wall and mark the cut line. The required gap between the coating and the wall must be maintained. Based on the measurements taken, the required length is cut and inserted into the overall structure.

The second and subsequent rows begin with the remaining cut lamella, but only if it is at least 30 cm in length. In all other cases, a cut is made from a new sheet. All elements of this row are assembled without a locking connection with the previous one. Only after the second row is completely joined, the entire structure snaps into place. It is not recommended to use a hammer to tightly adhere the elements.However, if the need arises, you can place a wooden block in places where there is a loose connection and secure the locks with light blows.

Following the basic recommendations, you need to fill all the space on the floor. Only areas with uneven surfaces or containing communication elements need special attention.

By following all the above tips, laying laminate flooring with your own hands will not be a painful ordeal for you.

Similar master classes

Particularly interesting

Comments (0)