Electric winch made from a car windshield wiper and a bicycle hub

To lift heavy loads to great heights, you can make an electric winch from the gearmotor of the windshield wiper drive. It effectively handles loads up to 150 kg. It can be used to lift building materials onto the roof, remove small engines from cars, etc.

The windshield wiper gear motor will be used as a drive for the electric winch.

On its shaft you need to make a 6-tooth sprocket for a bicycle chain.

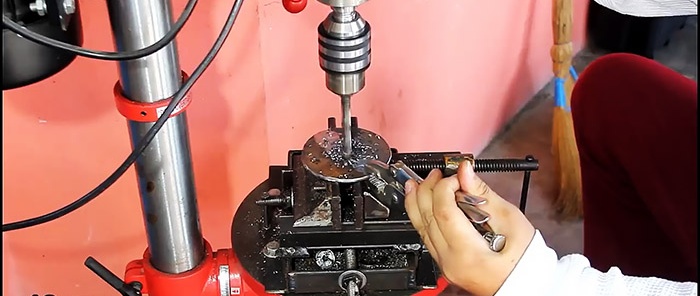

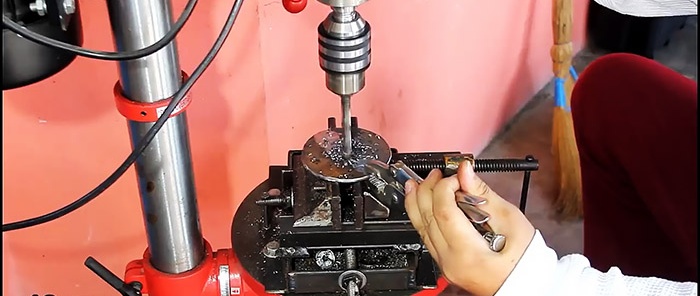

To do this, a circle with a radius of 12 mm is drawn on sheet steel using a mechanic’s compass. Along its circumference you need to mark 6 points, keeping the same distance between them.

Then, using a drill that matches the diameter of the roller of the existing chain, you need to drill holes at the points. A hole of a larger diameter is made in the center of the circle for the gearmotor shaft.

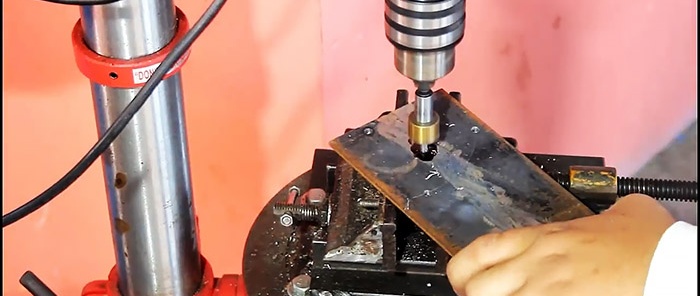

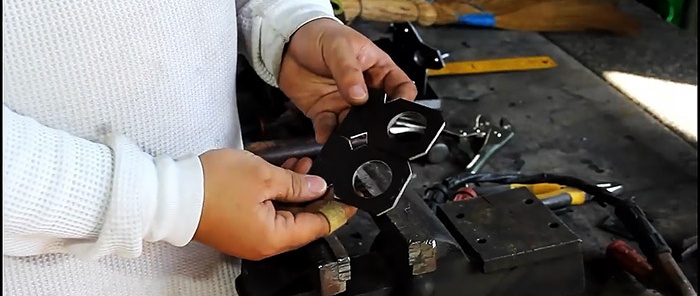

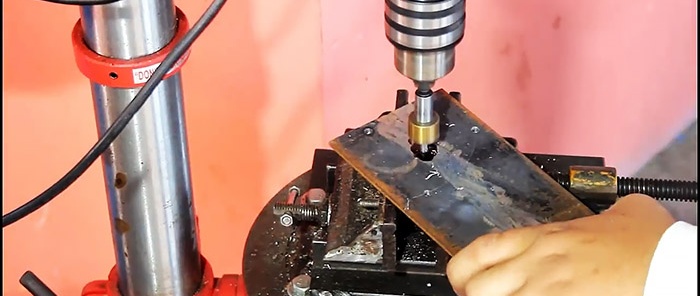

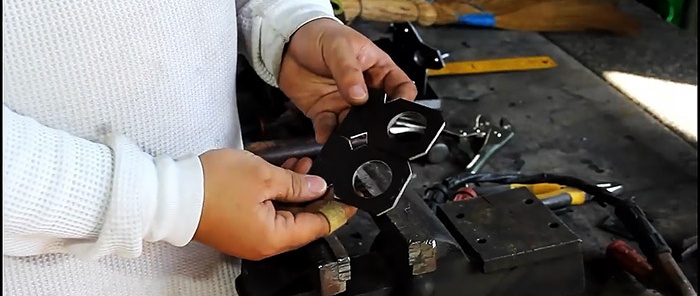

Using a core drill, you need to drill out a star from the metal.

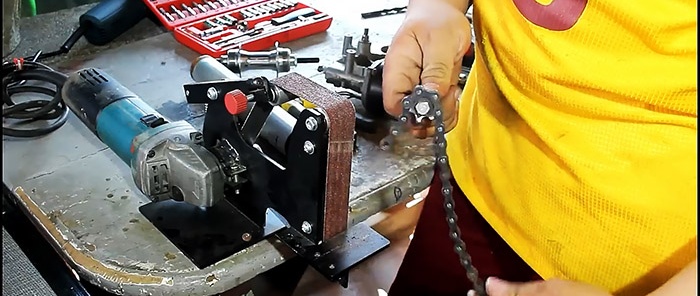

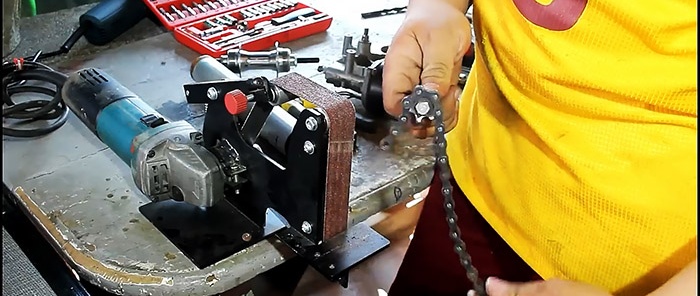

A bolt is threaded into the resulting workpiece, and it is tightened with a nut. The bolt is then inserted into the chuck of a screwdriver or drill. The next step requires sanding the sprocket while rotating it with a screwdriver. In this case, the machined teeth will be identical.

To make the winch drum, parts from a bicycle wheel hub are used. First, you need to cut 2 disks with a diameter of 90 mm from sheet steel, and make a hole in their center 0.5-1 mm wider than the diameter of the existing bicycle axle.

After this, the discs are welded to a 50 mm piece of pipe, resulting in a coil.

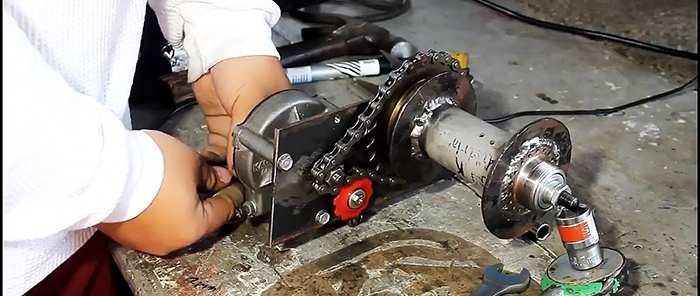

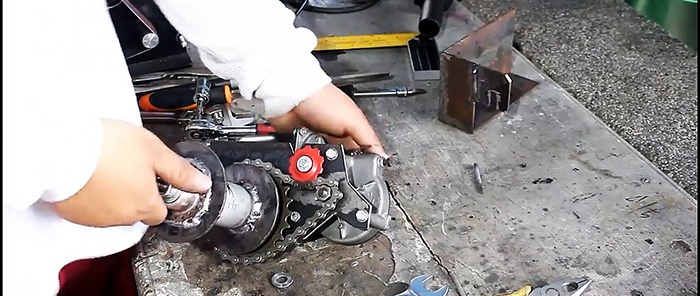

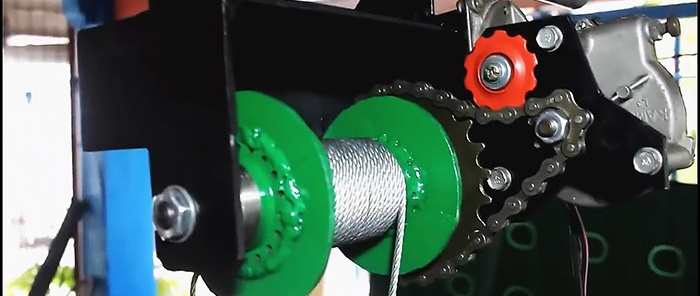

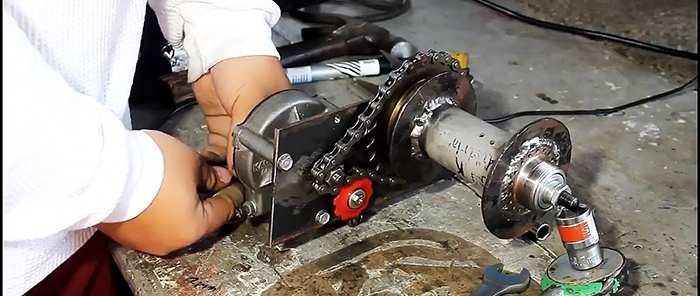

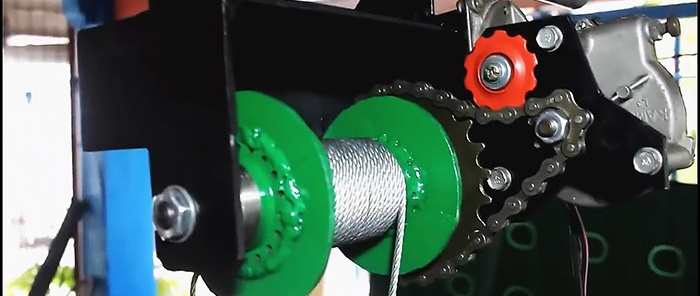

Next, you need to insert the bicycle axle into the drum, place cups from the hub on the sides, assemble bulk bearings, tighten the nuts and, after centering, weld the cups to the disks. Then a 24 tooth sprocket with a ratchet is installed on the drum.

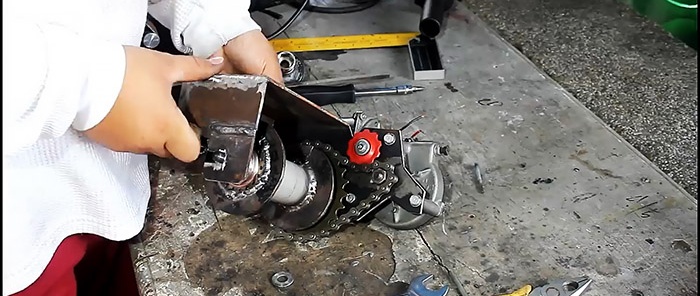

At the next stage, the winch body is made from sheet steel. First, a plate is cut to install the gearmotor. Holes are drilled in it for its fasteners and shaft.

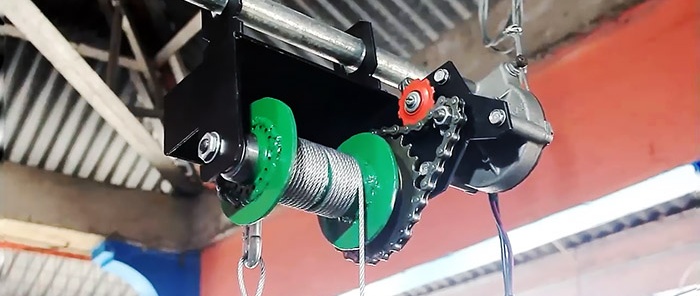

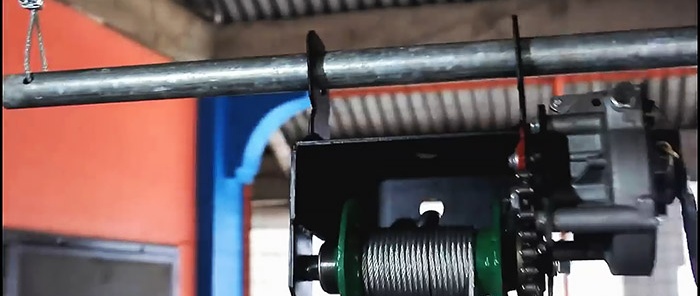

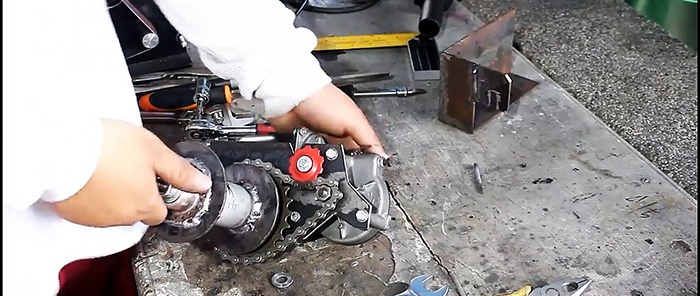

Afterwards, a homemade sprocket is installed on the shaft. The drum axis is fixed a little to the side. A chain is stretched between the sprockets. To prevent it from sagging, a tensioner roller is also mounted on the plate.

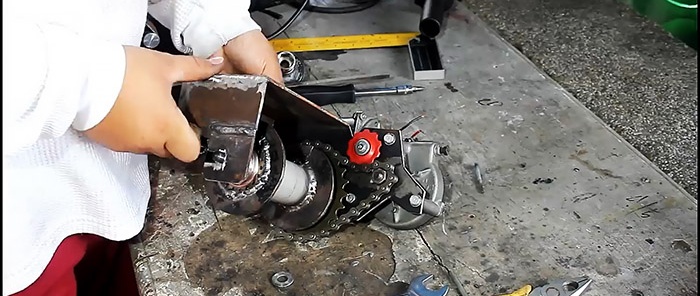

After adjusting and checking the working part, the gearmotor and sprockets are removed. Removing unnecessary metal with a grinder

Next you need to weld the winch body.

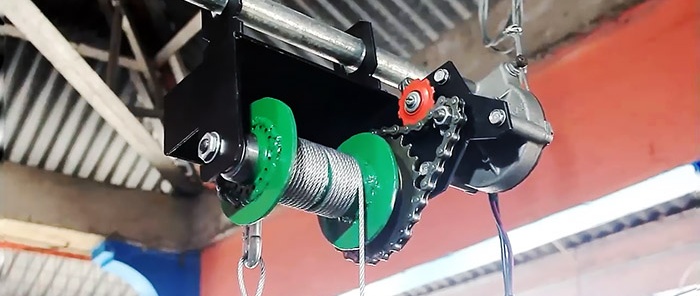

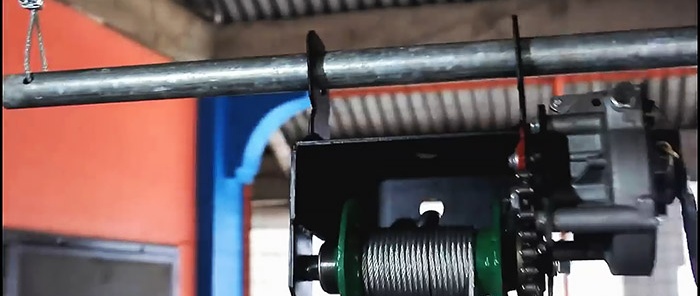

A holder for the drum axis is made of a similar design as the mounting plate, a jumper is welded between them, and on top of it there are eyes for hanging the winch.

After welding, the body is painted, and sprockets with a gearmotor are installed on it.

The cable is wound around the drum.

To securely fasten it, you need to make 3 holes in one disk. The cable is passed through them, after which its end is tightened in a loop. In this form, provided there is a tail of 3-5 cm, it will not break out.

The result is a lightweight, compact winch powered by a car battery.

If, when assembling it, you use not bicycle parts, but more powerful ones, for example, from a seeder or other agricultural machinery, then the load capacity and safety during overload will increase.

We lift a compressor weighing 60 kg.

Thanks to the use of a chain hoist, the force is divided in half.

We lift a drilling machine weighing 100 kg.

There are no problems. When the polarity of the electric motor power supply changes, the direction of rotation of the winch coil also changes.

Materials:

- windshield wiper drive gearmotor;

- sheet steel with a cross section of 3-4 mm;

- front bicycle wheel hub;

- bicycle chain;

- steel pipe d50 mm;

- 24 tooth sprocket with ratchet;

- bicycle chain tensioner sprocket;

- steel cable 3 mm.

Making a winch

The windshield wiper gear motor will be used as a drive for the electric winch.

On its shaft you need to make a 6-tooth sprocket for a bicycle chain.

To do this, a circle with a radius of 12 mm is drawn on sheet steel using a mechanic’s compass. Along its circumference you need to mark 6 points, keeping the same distance between them.

Then, using a drill that matches the diameter of the roller of the existing chain, you need to drill holes at the points. A hole of a larger diameter is made in the center of the circle for the gearmotor shaft.

Using a core drill, you need to drill out a star from the metal.

A bolt is threaded into the resulting workpiece, and it is tightened with a nut. The bolt is then inserted into the chuck of a screwdriver or drill. The next step requires sanding the sprocket while rotating it with a screwdriver. In this case, the machined teeth will be identical.

To make the winch drum, parts from a bicycle wheel hub are used. First, you need to cut 2 disks with a diameter of 90 mm from sheet steel, and make a hole in their center 0.5-1 mm wider than the diameter of the existing bicycle axle.

After this, the discs are welded to a 50 mm piece of pipe, resulting in a coil.

Next, you need to insert the bicycle axle into the drum, place cups from the hub on the sides, assemble bulk bearings, tighten the nuts and, after centering, weld the cups to the disks. Then a 24 tooth sprocket with a ratchet is installed on the drum.

At the next stage, the winch body is made from sheet steel. First, a plate is cut to install the gearmotor. Holes are drilled in it for its fasteners and shaft.

Afterwards, a homemade sprocket is installed on the shaft. The drum axis is fixed a little to the side. A chain is stretched between the sprockets. To prevent it from sagging, a tensioner roller is also mounted on the plate.

After adjusting and checking the working part, the gearmotor and sprockets are removed. Removing unnecessary metal with a grinder

Next you need to weld the winch body.

A holder for the drum axis is made of a similar design as the mounting plate, a jumper is welded between them, and on top of it there are eyes for hanging the winch.

After welding, the body is painted, and sprockets with a gearmotor are installed on it.

The cable is wound around the drum.

To securely fasten it, you need to make 3 holes in one disk. The cable is passed through them, after which its end is tightened in a loop. In this form, provided there is a tail of 3-5 cm, it will not break out.

The result is a lightweight, compact winch powered by a car battery.

If, when assembling it, you use not bicycle parts, but more powerful ones, for example, from a seeder or other agricultural machinery, then the load capacity and safety during overload will increase.

We lift a compressor weighing 60 kg.

Thanks to the use of a chain hoist, the force is divided in half.

We lift a drilling machine weighing 100 kg.

There are no problems. When the polarity of the electric motor power supply changes, the direction of rotation of the winch coil also changes.

Watch the video

Similar master classes

Restoring plastic gear teeth by knurling

Circular machine made from a bicycle hub and a washing machine motor

Replacing trimmer line with steel cable

How to make an electric bike with 4 low-power motors,

A center punch from an automobile valve that does not give in the hand

Elastic band “Star” made of satin ribbons

Particularly interesting

Comments (2)