Simple technology for pouring a concrete floor

One of the important stages in the construction technology of a modern building is pouring a concrete floor in the future room. It is best to carry out this part of the construction work after completing the laying of the basement of the building, if, of course, the weather is favorable. But in principle you can do this later.

Creating a soil base.

The fact is that the floor surface is usually made at the same level as the top of the base. This guideline allows you to determine at what depth inside the built-up space you need to prepare the earthen base for pouring. It is very important to immediately remove the fertile soil layer from the entire area being prepared for concreting. The earthen base should be 20 cm below the top of the plinth, and in cases where the floor needs to be insulated, the thickness of the thermal insulation should be taken into account. After removing the fertile layer, it may be necessary to either further deepen or raise the level of the base surface using imported alumina.

If the soil in the area being built is loose or the soil needs to be filled up to the required level, then in the process of preparing the base surface, compaction measures should be carried out using a vibrating plate or a manual tamper.

It is important to take into account that by tamping a large layer of earth at once, it will not be possible to achieve the expected result, which is why in the future the floor may sag and cracks will appear in the concrete. The soil must be compacted as it is added every 5 cm of the layer being created.

Forming a sand cushion.

When the earthen base is prepared, you can begin adding a layer of sand 10 cm thick. It would not hurt to stretch several parallel lines across the width at the height of the plane of the surface of the floor being created to take the necessary measurements, so that you can easily control the level to which sand is added.

It must be evenly distributed using shovels and a rule, and also compacted well in the manner described above.

Upon completion of the formation of the sand layer, in principle, you can begin concreting, but if it was planned to make a floor with a heat-insulating layer, then before starting pouring it is necessary to lay the insulation.

When the floor needs to be insulated.

A suitable material used to insulate a concrete floor in a house is regular or extruded foam. The second option is more reliable, since it is much denser than the first, which reduces the risk of subsidence of the concrete layer, leading to deformation and cracking of the floor during the operation of the building. Sheets of expanded polystyrene are simply laid on a sand cushion, trying to join them so as not to leave gaps between them.

If necessary, parts of appropriate sizes are cut out from a whole sheet to cover the missing areas.It wouldn’t hurt to put a waterproofing coating on top of the foam, for example, thick oilcloth.

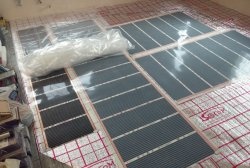

In order for the load on the insulation to be distributed more evenly during the operation of the floor, it is necessary to place a metal mesh for reinforcement in the lower part of the concrete layer. To do this, it must be placed on top of the foam before pouring begins.

When there is a need for reinforcement.

In premises used for production purposes, the operational load on the floor can be quite large due to the movement of various transport and loading equipment or the storage of heavy products. In this case, concrete is reinforced during the process of pouring it.

To complete this task, you must first tie a frame of steel rods, the cross-sectional diameter of which is taken depending on the load expected during operation of the floor. The frame is made lattice by welding or twisting together with wire longitudinally and perpendicularly laid pieces of reinforcement, the distance between which is also determined by technological calculations of the required strength of the reinforced concrete structure.

Installation of beacons.

The next preparatory step towards pouring the floor is the installation of guides that allow you to set the height of its surface level, called beacons. Using a rule, concrete will be pulled together along them, due to which its surface will be smooth. Typically, a rectangular or round metal pipe is used as such beacons. But to install the pipe in the desired position, that is, so that its top is level with the top of the base, special supports should be created from fresh concrete.To ensure that the supports over the entire area prepared for pouring have the appropriate and uniform height, you can use a level installed in a fixed position to measure this parameter.

When the supports for the lighthouses are made, pipes can be laid on them, after which the concreted space will be ready for pouring.

Concreting process.

It is important to properly organize the timely delivery of concrete to the work site, since the concrete structure being created must be monolithic.

If the pouring area is small, then you can mix the working mixture yourself with the help of several assistants. But pouring a larger space means increasing the number of workers and, possibly, the use of additional concrete mixers, since it will be difficult to make a concrete floor monolithic with little effort due to the fact that the production process will stretch to infinity.

The easiest way is to order factory-made concrete, which will be delivered by a mixer to the construction site and, using a pump, as well as a guide device included with this machine, will be unloaded directly into the space to be poured.

Of course, several people will be needed to quickly distribute the working substance with shovels.

Two more workers should gradually pull the concrete along the beacons using a rule or a flat board, leveling its surface.

It is important to pull the rule not only along the pipe, but also to make movements reminiscent of working with a saw.

Upon completion of this procedure, while the concrete mixture has not yet hardened, it is necessary to remove the pipes from it that served as beacons and immediately fill the resulting grooves with fresh concrete.

Then you need to rub the concrete using a special device until a liquid film forms on its surface.

The emerging liquid is a sign that it’s time to start ironing, that is, applying a thin layer of cement 2-3 mm thick on top. In the end, all that remains is to smooth the floor surface, which can be done using an apparatus colloquially called a helicopter, after which the floor surface will look like the one shown in the photo below.

The presented floor filling technology is the simplest and most economical in terms of technological nuances. More complex and expensive methods may include additional measures during insulation, reinforcement, and preparation of the base for pouring, but in most cases there is no need to use these methods. By adhering to the scheme described above, you can be completely confident in the reliability and durability of the concrete structure being created.

Creating a soil base.

The fact is that the floor surface is usually made at the same level as the top of the base. This guideline allows you to determine at what depth inside the built-up space you need to prepare the earthen base for pouring. It is very important to immediately remove the fertile soil layer from the entire area being prepared for concreting. The earthen base should be 20 cm below the top of the plinth, and in cases where the floor needs to be insulated, the thickness of the thermal insulation should be taken into account. After removing the fertile layer, it may be necessary to either further deepen or raise the level of the base surface using imported alumina.

If the soil in the area being built is loose or the soil needs to be filled up to the required level, then in the process of preparing the base surface, compaction measures should be carried out using a vibrating plate or a manual tamper.

It is important to take into account that by tamping a large layer of earth at once, it will not be possible to achieve the expected result, which is why in the future the floor may sag and cracks will appear in the concrete. The soil must be compacted as it is added every 5 cm of the layer being created.

Forming a sand cushion.

When the earthen base is prepared, you can begin adding a layer of sand 10 cm thick. It would not hurt to stretch several parallel lines across the width at the height of the plane of the surface of the floor being created to take the necessary measurements, so that you can easily control the level to which sand is added.

It must be evenly distributed using shovels and a rule, and also compacted well in the manner described above.

Upon completion of the formation of the sand layer, in principle, you can begin concreting, but if it was planned to make a floor with a heat-insulating layer, then before starting pouring it is necessary to lay the insulation.

When the floor needs to be insulated.

A suitable material used to insulate a concrete floor in a house is regular or extruded foam. The second option is more reliable, since it is much denser than the first, which reduces the risk of subsidence of the concrete layer, leading to deformation and cracking of the floor during the operation of the building. Sheets of expanded polystyrene are simply laid on a sand cushion, trying to join them so as not to leave gaps between them.

If necessary, parts of appropriate sizes are cut out from a whole sheet to cover the missing areas.It wouldn’t hurt to put a waterproofing coating on top of the foam, for example, thick oilcloth.

In order for the load on the insulation to be distributed more evenly during the operation of the floor, it is necessary to place a metal mesh for reinforcement in the lower part of the concrete layer. To do this, it must be placed on top of the foam before pouring begins.

When there is a need for reinforcement.

In premises used for production purposes, the operational load on the floor can be quite large due to the movement of various transport and loading equipment or the storage of heavy products. In this case, concrete is reinforced during the process of pouring it.

To complete this task, you must first tie a frame of steel rods, the cross-sectional diameter of which is taken depending on the load expected during operation of the floor. The frame is made lattice by welding or twisting together with wire longitudinally and perpendicularly laid pieces of reinforcement, the distance between which is also determined by technological calculations of the required strength of the reinforced concrete structure.

Installation of beacons.

The next preparatory step towards pouring the floor is the installation of guides that allow you to set the height of its surface level, called beacons. Using a rule, concrete will be pulled together along them, due to which its surface will be smooth. Typically, a rectangular or round metal pipe is used as such beacons. But to install the pipe in the desired position, that is, so that its top is level with the top of the base, special supports should be created from fresh concrete.To ensure that the supports over the entire area prepared for pouring have the appropriate and uniform height, you can use a level installed in a fixed position to measure this parameter.

When the supports for the lighthouses are made, pipes can be laid on them, after which the concreted space will be ready for pouring.

Concreting process.

It is important to properly organize the timely delivery of concrete to the work site, since the concrete structure being created must be monolithic.

If the pouring area is small, then you can mix the working mixture yourself with the help of several assistants. But pouring a larger space means increasing the number of workers and, possibly, the use of additional concrete mixers, since it will be difficult to make a concrete floor monolithic with little effort due to the fact that the production process will stretch to infinity.

The easiest way is to order factory-made concrete, which will be delivered by a mixer to the construction site and, using a pump, as well as a guide device included with this machine, will be unloaded directly into the space to be poured.

Of course, several people will be needed to quickly distribute the working substance with shovels.

Two more workers should gradually pull the concrete along the beacons using a rule or a flat board, leveling its surface.

It is important to pull the rule not only along the pipe, but also to make movements reminiscent of working with a saw.

Upon completion of this procedure, while the concrete mixture has not yet hardened, it is necessary to remove the pipes from it that served as beacons and immediately fill the resulting grooves with fresh concrete.

Then you need to rub the concrete using a special device until a liquid film forms on its surface.

The emerging liquid is a sign that it’s time to start ironing, that is, applying a thin layer of cement 2-3 mm thick on top. In the end, all that remains is to smooth the floor surface, which can be done using an apparatus colloquially called a helicopter, after which the floor surface will look like the one shown in the photo below.

The presented floor filling technology is the simplest and most economical in terms of technological nuances. More complex and expensive methods may include additional measures during insulation, reinforcement, and preparation of the base for pouring, but in most cases there is no need to use these methods. By adhering to the scheme described above, you can be completely confident in the reliability and durability of the concrete structure being created.

Similar master classes

Particularly interesting

Comments (1)