DIY paving slabs

Tile prices have recently begun to rise seriously. Although there is absolutely nothing in short supply there. I have been making tiles myself for my own needs for a long time and therefore occasionally watch the prices on the market. The process is not that tricky, but rather elementary. A little more difficult than making sand cakes.

The cost of this tile is determined only by the prices of cement and sand, and I get the sand for free. I usually use my tiles to lay out paths and paths in the garden and vegetable garden. Once I even laid out a parking lot for her car.

We start by preparing a cement solution. I take the proportions: 4 buckets of sand, 1 bucket of cement, 1 bucket of water. Mix everything well and pour into wooden molds. That's all.

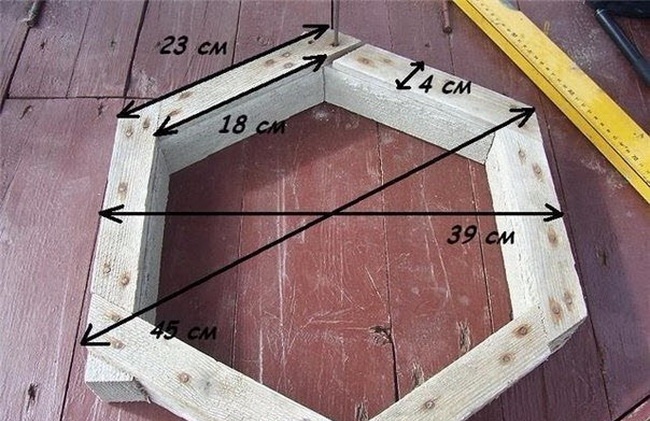

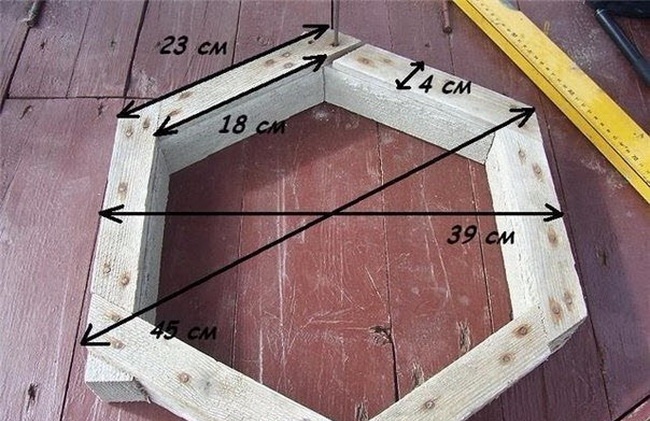

Wood molds made by hand have served me for more than 5 years. The main contour is a beam, and on top there is a rail, which actually holds the entire structure.

I made ten such forms.

I mix the solution in a plastic bowl (it is very easy to clean) and measure the proportions with a plastic mayonnaise bucket. I already know how much solution is needed for all ten forms, and therefore I mix it exactly so that there is no excess left.

Be sure to use rubber gloves when handling the solution, otherwise the solution will quickly corrode your hands.

I filled the molds with the solution and waited a day for it to harden. That is, the productivity rate is 10 tiles per day and 70 tiles per week. I usually fill it in the evening, after a day I take it out and fill it with a new solution.

That's 300 pieces a month! And this is without much difficulty!

If the tiles will be subject to heavy loads, I recommend placing a piece of steel grating in the middle when pouring the mortar for strength. Well, if it’s for pedestrians, then it’s fine.

Laying the tiles is also very simple.

We dig a groove for the tile approximately at the height of the tile. We align the path in width and height. It is necessary. We compact the earth a little. Then we put a layer of sand. Well, we lay the tiles on top at a short distance from each other so that in winter everything does not crack or burst. Once everything is laid, we fill the cracks with sand. That's all - you can walk safely.

You can come up with other shapes for tile molds. I made the simplest ones. They are very easy to put together. Even simpler are just squares.

You can and should make tiles yourself. This process will save you a lot of money. This is even an idea for a business that can make good money. It’s fashionable to start selling with your neighbors. Those who live in private houses almost always need tiles. So take note. Good luck!

The cost of this tile is determined only by the prices of cement and sand, and I get the sand for free. I usually use my tiles to lay out paths and paths in the garden and vegetable garden. Once I even laid out a parking lot for her car.

Tile production

We start by preparing a cement solution. I take the proportions: 4 buckets of sand, 1 bucket of cement, 1 bucket of water. Mix everything well and pour into wooden molds. That's all.

Wood molds made by hand have served me for more than 5 years. The main contour is a beam, and on top there is a rail, which actually holds the entire structure.

I made ten such forms.

I mix the solution in a plastic bowl (it is very easy to clean) and measure the proportions with a plastic mayonnaise bucket. I already know how much solution is needed for all ten forms, and therefore I mix it exactly so that there is no excess left.

Be sure to use rubber gloves when handling the solution, otherwise the solution will quickly corrode your hands.

I filled the molds with the solution and waited a day for it to harden. That is, the productivity rate is 10 tiles per day and 70 tiles per week. I usually fill it in the evening, after a day I take it out and fill it with a new solution.

That's 300 pieces a month! And this is without much difficulty!

If the tiles will be subject to heavy loads, I recommend placing a piece of steel grating in the middle when pouring the mortar for strength. Well, if it’s for pedestrians, then it’s fine.

Laying paving slabs

Laying the tiles is also very simple.

We dig a groove for the tile approximately at the height of the tile. We align the path in width and height. It is necessary. We compact the earth a little. Then we put a layer of sand. Well, we lay the tiles on top at a short distance from each other so that in winter everything does not crack or burst. Once everything is laid, we fill the cracks with sand. That's all - you can walk safely.

Tile shape.

You can come up with other shapes for tile molds. I made the simplest ones. They are very easy to put together. Even simpler are just squares.

Conclusion

You can and should make tiles yourself. This process will save you a lot of money. This is even an idea for a business that can make good money. It’s fashionable to start selling with your neighbors. Those who live in private houses almost always need tiles. So take note. Good luck!

Similar master classes

Particularly interesting

Comments (1)