How to replace fishing line in a trimmer with steel cable

It is quite difficult to mow reeds, thick dry grass and small bushes using a fishing line, especially the most common one - round in cross-section. For such cases, you will need a two-component cord consisting of different materials: a durable metal core, which is located inside a nylon fishing line.

However, among all types of cords, this is the most expensive, and it is not often on sale, so it is not easy to find. But it is possible to make an analogue of such a working element of the trimmer with your own hands from quite accessible and inexpensive materials.

Everything you need for work can be found in the household or bought in a store, spending very little money:

The tools that we will need for the job also cannot be classified as rare and hard-to-find items:

On the outer generatrix of the cup-shaped bushing on the back side, using a ruler and a marker, mark two marks on diameters perpendicular to each other.

Then, focusing on the first four marks, we transfer them to the middle of the side surface of the cup-shaped bushing strictly vertically.

We clamp the cup-shaped bushing in a bench vice and in the marked places, using a core and a hammer, mark the drilling points, which we do with a drill. You should get two opposite holes, located at perpendicular diameters.

We clean the metal around all four holes, processing them one by one with a hand file.

Above each of the four holes on the outside we install and weld a nut with a rounded top.

We clamp two bolts in series in a vice and drill through holes with a diameter of slightly more than two millimeters directly under the heads.

We screw the nuts onto them and place both bolts with the screwed nuts into the annular recess of the cup-shaped bushing with their heads inward, symmetrically between two holes opposite each other.

The location of the bolts should be such that the nuts on them can be twisted and unscrewed freely from the head to the top of the holes drilled in them.

After making sure once again that the bolts are laid correctly, we weld them to the bushing on both sides.

We unwind a two-millimeter cable and pass it at one end through any of the side holes in the cup-shaped sleeve towards the bolt.We pass the hole in it with the rope and pull the end of the rope out through the hole in the sleeve on the other side of the bolt, helping ourselves with wire cutters.

We set the required length of the elongated cord and, having measured the same size on the other side, cut the cord in the intended place with wire cutters.

We do the same with the second “antennae”, and tighten the nuts on the bolts using an open-end wrench with a force sufficient to securely fix the “antennae” in a given position.

Usually, tendrils at high operating speeds quickly become frayed, lose strength and begin to break under the influence of enormous centrifugal force. These impair the performance of the trimmer, but more dangerously, they can injure the legs of the operator or people nearby.

Therefore, you should make a shell of solder using a soldering iron along the entire length of the “antennae” of the cable. Soft solder, which has significant plasticity, when in contact with the stems of grass and small bushes, absorbs most of the impact force and, thereby, protects the cable from destruction. So, the homemade working part of the trimmer is ready.

We remove the plastic spool of fishing line from the lawn mower and instead install a self-assembled working part of the trimmer based on a two-millimeter steel rope. We securely tighten it with a nut with a left-hand thread using a socket wrench with a side handle, locking the drive from the back with a screwdriver through a special hole.

We make sure that none of the ends of the ropes touch the protective casing, which is one of the conditions for safe operation of this tool.To do this, we pull each “antennae” opposite the casing one by one with force by hand and note the presence of a quite noticeable gap between the ends of the antennae and the protective casing.

We go out with the tool to the place where weeds and bushes grow, and turn on the trimmer, having first covered our face with a transparent visor or at least protective glasses.

We are convinced that the work of a trimmer with a homemade working element based on a steel rope has become much more efficient and productive.

Do not get carried away with increasing the diameter used to make the “antennae” of the rope. This will lead to rapid wear of the drive and even breakdown of the trimmer motor, especially if it is electric, due to the increased effort. This also increases the likelihood of serious injury if the cable “tendril” breaks at high speeds.

However, among all types of cords, this is the most expensive, and it is not often on sale, so it is not easy to find. But it is possible to make an analogue of such a working element of the trimmer with your own hands from quite accessible and inexpensive materials.

Will need

Everything you need for work can be found in the household or bought in a store, spending very little money:

- a piece of two-millimeter steel cable (metal rope);

- a washer with a splined central hole and a flat washer;

- a cup-shaped sleeve with a central smooth hole;

- nut with left-hand thread (included with the trimmer);

- six nuts with rounded top edges;

- two bolts;

- standard solder.

The tools that we will need for the job also cannot be classified as rare and hard-to-find items:

- bench vice;

- core and hammer;

- drill and hand file;

- welding machine;

- soldering iron and wire cutters;

- socket wrench with side handle.

Making a cable cord holder

On the outer generatrix of the cup-shaped bushing on the back side, using a ruler and a marker, mark two marks on diameters perpendicular to each other.

Then, focusing on the first four marks, we transfer them to the middle of the side surface of the cup-shaped bushing strictly vertically.

We clamp the cup-shaped bushing in a bench vice and in the marked places, using a core and a hammer, mark the drilling points, which we do with a drill. You should get two opposite holes, located at perpendicular diameters.

We clean the metal around all four holes, processing them one by one with a hand file.

Above each of the four holes on the outside we install and weld a nut with a rounded top.

We clamp two bolts in series in a vice and drill through holes with a diameter of slightly more than two millimeters directly under the heads.

We screw the nuts onto them and place both bolts with the screwed nuts into the annular recess of the cup-shaped bushing with their heads inward, symmetrically between two holes opposite each other.

The location of the bolts should be such that the nuts on them can be twisted and unscrewed freely from the head to the top of the holes drilled in them.

After making sure once again that the bolts are laid correctly, we weld them to the bushing on both sides.

We unwind a two-millimeter cable and pass it at one end through any of the side holes in the cup-shaped sleeve towards the bolt.We pass the hole in it with the rope and pull the end of the rope out through the hole in the sleeve on the other side of the bolt, helping ourselves with wire cutters.

We set the required length of the elongated cord and, having measured the same size on the other side, cut the cord in the intended place with wire cutters.

We do the same with the second “antennae”, and tighten the nuts on the bolts using an open-end wrench with a force sufficient to securely fix the “antennae” in a given position.

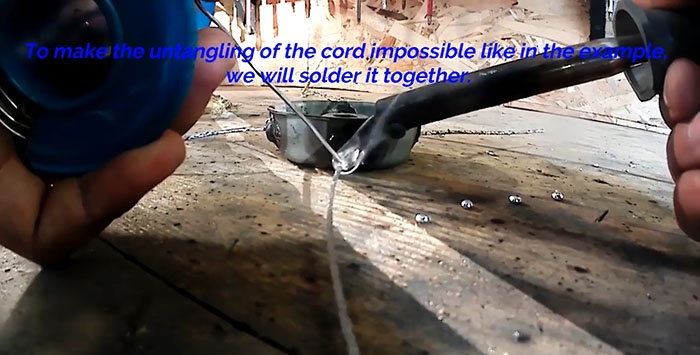

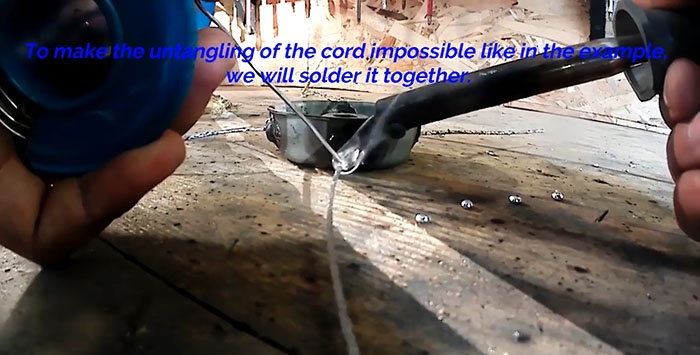

Usually, tendrils at high operating speeds quickly become frayed, lose strength and begin to break under the influence of enormous centrifugal force. These impair the performance of the trimmer, but more dangerously, they can injure the legs of the operator or people nearby.

Therefore, you should make a shell of solder using a soldering iron along the entire length of the “antennae” of the cable. Soft solder, which has significant plasticity, when in contact with the stems of grass and small bushes, absorbs most of the impact force and, thereby, protects the cable from destruction. So, the homemade working part of the trimmer is ready.

Installing a bushing with antennae-ropes on a trimmer

We remove the plastic spool of fishing line from the lawn mower and instead install a self-assembled working part of the trimmer based on a two-millimeter steel rope. We securely tighten it with a nut with a left-hand thread using a socket wrench with a side handle, locking the drive from the back with a screwdriver through a special hole.

We make sure that none of the ends of the ropes touch the protective casing, which is one of the conditions for safe operation of this tool.To do this, we pull each “antennae” opposite the casing one by one with force by hand and note the presence of a quite noticeable gap between the ends of the antennae and the protective casing.

Testing homemade products in action

We go out with the tool to the place where weeds and bushes grow, and turn on the trimmer, having first covered our face with a transparent visor or at least protective glasses.

We are convinced that the work of a trimmer with a homemade working element based on a steel rope has become much more efficient and productive.

Warning

Do not get carried away with increasing the diameter used to make the “antennae” of the rope. This will lead to rapid wear of the drive and even breakdown of the trimmer motor, especially if it is electric, due to the increased effort. This also increases the likelihood of serious injury if the cable “tendril” breaks at high speeds.

Watch the video

Similar master classes

Particularly interesting

Comments (19)