How to sharpen hair clipper blades

Ideally, the blades should be sharpened after each use, but this is usually done when cutting pain occurs due to the fact that the blades are dull and do not cut hair, but pull it out.

To sharpen knives with high quality, you need to be patient, be precise and prepare the necessary accessories:

To tidy up dull knives, remove them from the machine and thoroughly clean them with a paper or cloth napkin to remove residual grease, dust and hair. Now they are completely ready for the sharpening process.

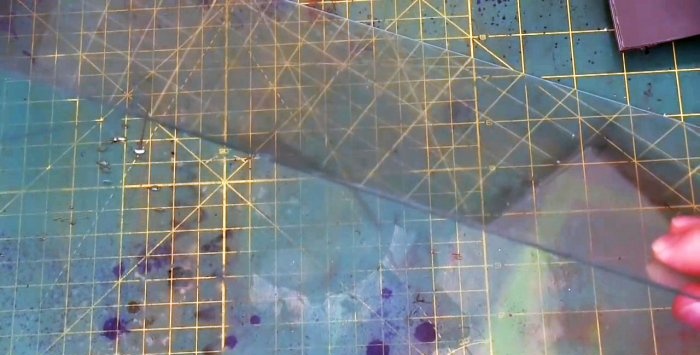

1. Place ordinary or organic glass of sufficient rigidity on a horizontal surface.

2.Place a sheet of P 600 grit sandpaper on the surface of the glass, which is quite enough for moderately worn blades.

3. Wet (pour) a little clean water onto the surface of the sandpaper, which is necessary to form a water-abrasive suspension, which mainly provides sharpening.

4. Then we begin, pressing lightly, to move the knife with the cutting surface along the sandpaper, tracing the trajectory of the number eight. This allows you to level out the inevitable errors of manual sharpening: after all, the “figure eight” is obtained by superimposing a reciprocating and circular motion. The duration of the operation depends on the degree of dullness of the knife and the material from which it is made.

5. Rinse the knife under plenty of water to remove all particles formed during processing on coarser sandpaper. If they remain on the blade, then when you switch to sandpaper with a smaller grain size, such particles will cause scuffing and the sharpening will be ruined.

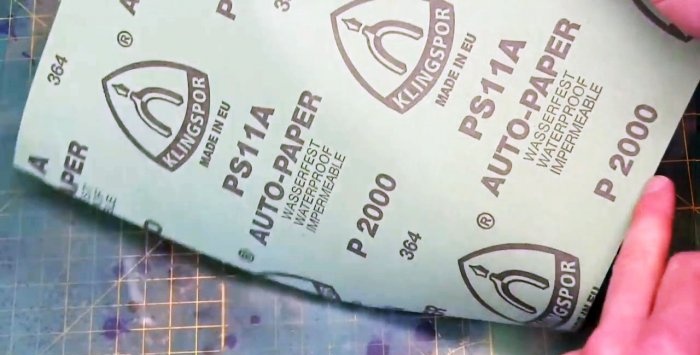

6. Remove the first sheet from the glass and replace it with a second one, but with a smaller grain size of P 2000.

We exactly repeat the operation performed in step 4. Except that the pressure can be reduced a little. And to prevent your fingers from becoming numb when sharpening knives for a long time due to their small height, you can install a round cylindrical magnet on the upper surface of the blade and use it instead of a handle.

Water flows off with wear products.

The quality of sharpening is determined visually: if it is high, then the knife will have a mirror appearance over its entire surface and be very smooth to the touch. Before installing the knives in place, they must be lubricated with oil specially designed for this purpose.

If there is no such lubricant, then silicone oil should be preferred to machine oil.It is absolutely contraindicated to lubricate knives with vegetable oil.

Will need

To sharpen knives with high quality, you need to be patient, be precise and prepare the necessary accessories:

- glass of sufficient size or a mirror as a base;

- waterproof sandpaper with grit P 600 and P 2000;

- small cylindrical magnet;

- water source;

- paper or soft cloth;

- special lubricant (silicone can be used).

The process of sharpening a clipper

To tidy up dull knives, remove them from the machine and thoroughly clean them with a paper or cloth napkin to remove residual grease, dust and hair. Now they are completely ready for the sharpening process.

1. Place ordinary or organic glass of sufficient rigidity on a horizontal surface.

2.Place a sheet of P 600 grit sandpaper on the surface of the glass, which is quite enough for moderately worn blades.

3. Wet (pour) a little clean water onto the surface of the sandpaper, which is necessary to form a water-abrasive suspension, which mainly provides sharpening.

4. Then we begin, pressing lightly, to move the knife with the cutting surface along the sandpaper, tracing the trajectory of the number eight. This allows you to level out the inevitable errors of manual sharpening: after all, the “figure eight” is obtained by superimposing a reciprocating and circular motion. The duration of the operation depends on the degree of dullness of the knife and the material from which it is made.

5. Rinse the knife under plenty of water to remove all particles formed during processing on coarser sandpaper. If they remain on the blade, then when you switch to sandpaper with a smaller grain size, such particles will cause scuffing and the sharpening will be ruined.

6. Remove the first sheet from the glass and replace it with a second one, but with a smaller grain size of P 2000.

We exactly repeat the operation performed in step 4. Except that the pressure can be reduced a little. And to prevent your fingers from becoming numb when sharpening knives for a long time due to their small height, you can install a round cylindrical magnet on the upper surface of the blade and use it instead of a handle.

Water flows off with wear products.

Result

The quality of sharpening is determined visually: if it is high, then the knife will have a mirror appearance over its entire surface and be very smooth to the touch. Before installing the knives in place, they must be lubricated with oil specially designed for this purpose.

If there is no such lubricant, then silicone oil should be preferred to machine oil.It is absolutely contraindicated to lubricate knives with vegetable oil.

Watch the video

Similar master classes

Particularly interesting

Comments (9)