The simplest device for sharpening knives at 30 degrees

I continue to sharpen the knife. I have already shown my homemade device for making descents (tapering surfaces of the blade). At the same time, I made a polishing disk, sewing several disks together so that they would not diverge. Next, the task was to sharpen the knife - to make cutting edges that form the cutting edge.

An attempt to sharpen it with a whetstone did not give me the result I needed, because the metal of the blade is hard and sharpening takes a lot of time. Therefore, I decided to make a homemade device similar to the one I made for forming slopes.

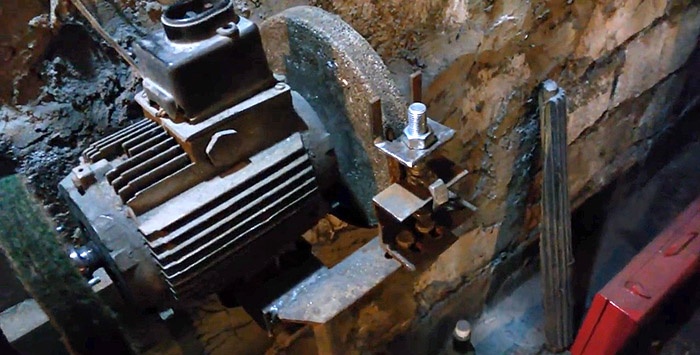

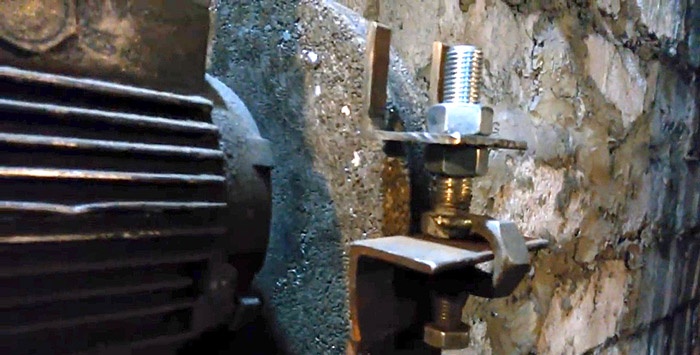

I installed the main part of the device - the angle - at the point where the surface of the grinding wheel is at an angle of 75 degrees to the vertical line. I used a regular corner piece and made a hole in the central part. I aligned the corners at 90 degrees so that the existing small semicircle would not interfere with work. I drilled a hole in the center for a 16mm bolt. A nut in the form of a clamp was welded to the bolt. A channel is installed at the bottom, the structure is pressed with a bolt and nut of 12.

The device can be raised or lowered with two nuts on the top bolt.When ascending, the sharpening angle will be larger, and when descending, it will be sharper (smaller). Using a clamp, the device can be moved towards the disk (for example, when the disk is ground down) or moved away from it.

The design can be simplified and you can install one long bolt so that you can immediately make descents or, lifting it higher, sharpen the knife to the desired angle.

The cutting edges are very smooth, as if made on a milling machine. If you correct the edges on a small block, the knife will be razor sharp. The result is an almost perfect sharpening. The advantage of this device is its very simple design, which can be assembled from scrap materials.

Watch the video

Similar master classes

Particularly interesting

Comments (15)