6 Woodworking Tips and Secrets

When working with wood, having a basic set of tools is not enough to perform the full range of possible tasks. Many things can be done only by using ingenuity, tricks and homemade devices. Let's look at 6 useful secrets that can improve the quality and convenience of woodworking.

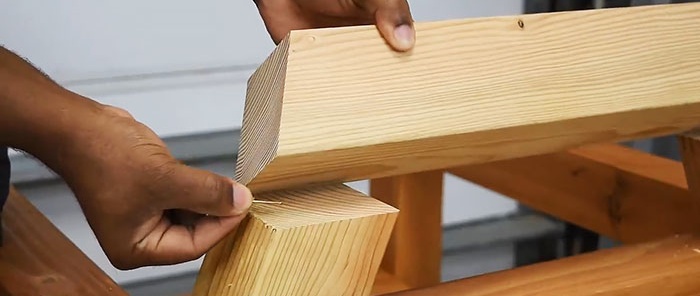

Manual thicknesser for longitudinal marking in the center

The first device is used for quick longitudinal marking of slats and planks in the center. This tool works on the principle of a manual surface planer, but does not provide for adjustment.

To make it, you need to take a small block with the correct geometry. It is marked in half lengthwise and crosswise. At the same distance from the drawn crosshairs, a dowel is glued into the prepared holes.

They need to be set exactly 90 degrees. After the glue has dried, a self-tapping screw is wrapped into the crosshair so that only its tip comes out of the block.

To mark, the tool is applied to the rail from the side of the dowels and turned to the side so that they rest against the bar. After this, it is drawn along, which leaves a scratch on the wood, made by the tip of the self-tapping screw.

Pressing clamp with elastic band

To glue an edge, profile or strip to the ends, it is convenient to use a modified clamp or clothespin with an elastic band. To do this, holes are made in its jaws through which a rubber ring is inserted. For tension, its edges are hooked onto the handles of the clothespin.

An improved clamp presses the end plate with an elastic band, and a spring on its jaws prevents the tool from loosening and moving away.

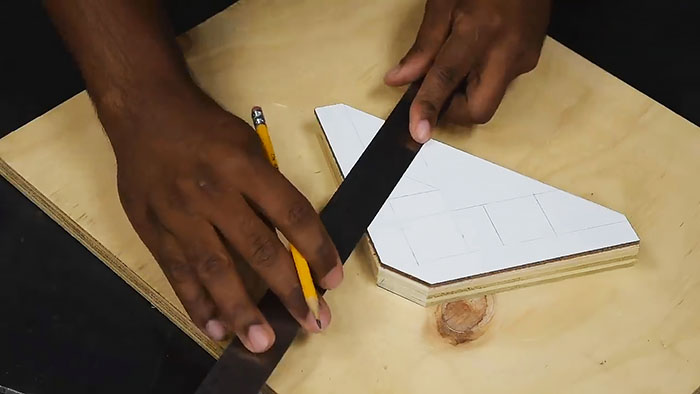

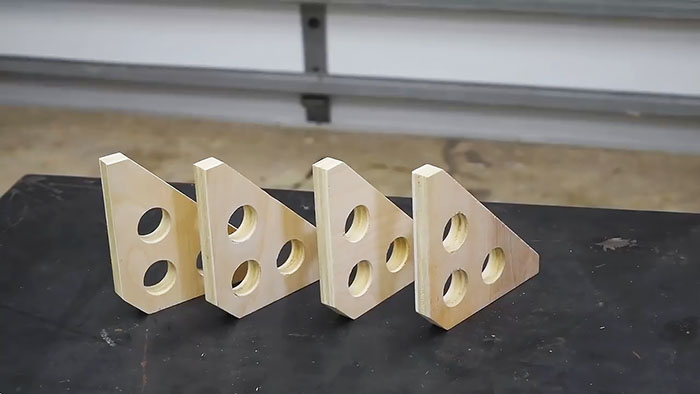

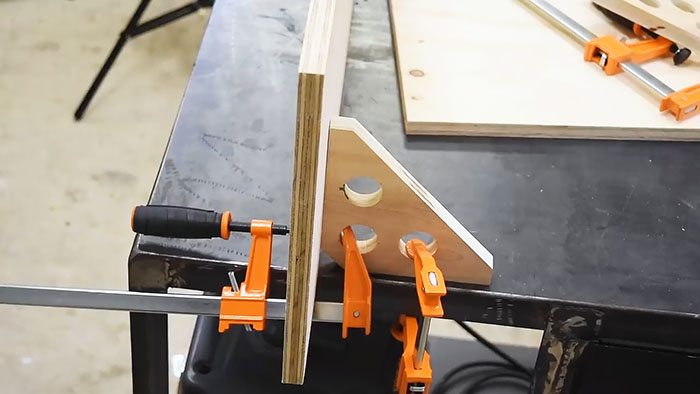

Corner template for furniture assembly

For assembly furniture at an angle of 90 degrees you can make simple patterns. Isosceles triangles are cut from plywood or boards. Their corners need to be cut down approximately 1 cm from the tops. In the triangles, 3 holes are drilled with a drill for installing hinges.

Through them, elements that need to be connected to each other at 90 degrees can be pressed to the template with a clamp.

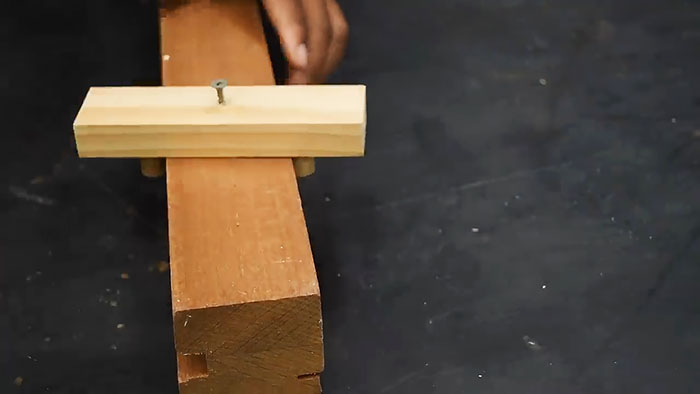

Adjustable Miter Saw Stop

When trimming a large number of identical long workpieces, you can make a special stop. It is made from slats and timber with a selected quarter to fit its size. The beam is fixed on the rail with a clamp and is used as a stop for workpieces.

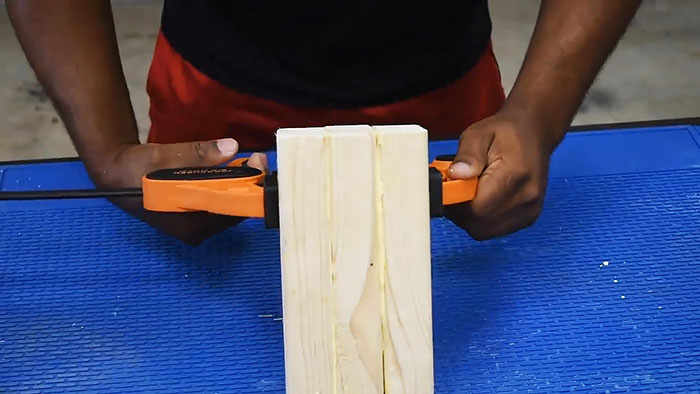

Salt and glue

When gluing workpieces and compressing them with a clamp, they tend to slide. To fix the elements to be glued and prevent them from moving, coarse salt is used. It is sprinkled onto the glue, after which the workpieces are applied to each other and no longer slip, since the salt acts as an abrasive.

Centering holes with a nail when drilling

If you need to connect the parts with a dowel, you need to make blind holes for it. In this case, it is difficult to get them to be opposite each other. To solve this problem you will need a small nail and masking tape.

The nail is glued flat with tape to one of the workpieces to be joined.Its cap should be located opposite the desired hole. Next, by applying the blanks and strongly squeezing them together, an imprint of the cap will remain on them.

The holes made on such marks will coincide with each other.

Watch the video

Similar master classes

Particularly interesting

Comments (0)