Simple induction heating

Induction heating has a significant advantage over heating elements. The main criterion here is the efficiency of converting electrical energy into heat. The article will talk about how to make a super simple induction heater from ready-made devices and parts. It will take you no more than two hours to build. With such a heater, with a power of about 1 kW, it will be possible to heat a room of approximately 30 sq.m.

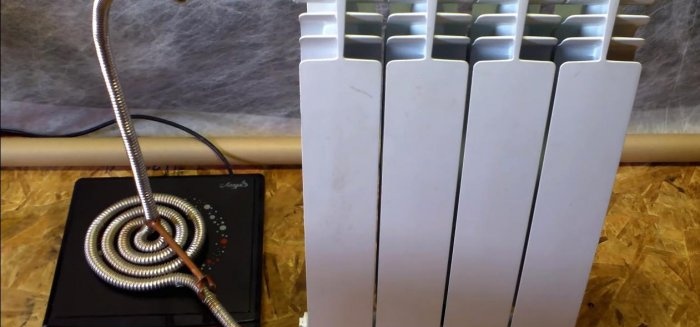

Radiator and tiles:

Any induction cooker has a power control, which can be used to regulate the heating temperature of the radiator.

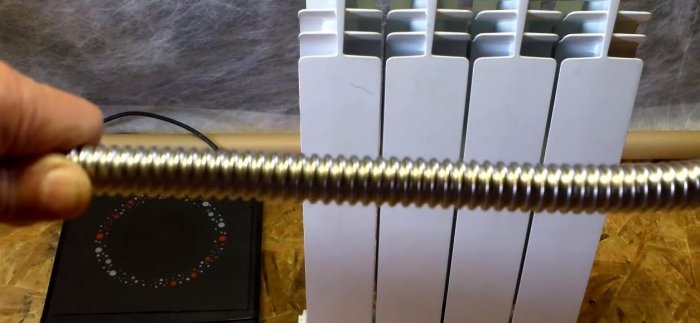

Corrugated pipe - water supply:

We bend the tube like a snail or a spiral. It bends easily with your hands.The area of the snail circle should be larger than the circular heating surface on the tile.

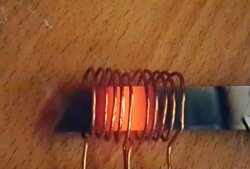

The main thing is not to forget to make a closing jumper for this circuit, otherwise nothing will work. I made it from a copper tube, soldering it to the beginning and end of the spiral. Now the circuit is closed and all the induction power will be directed into heating.

The induction boiler is ready. In fact, it consists of a purchased induction cooker and a made spiral through which water will be passed.

We screw the circuit to the battery.

We place a tile under the curl.

Pour water into the radiator. When heated, it will circulate in the system itself; in this case, an additional pump is not required.

Turn it on and check. First, set the minimum power on the stove, and then, if necessary, to the maximum.

On expensive models, you can immediately set the heating temperature and the tile itself will maintain it.

I calculated the approximate efficiency of an induction heater compared to a heater using heating elements. And it turned out that the efficiency of an induction heater is 3.5 times higher than that of a heating element heater.

For more detailed experiments and system upgrades, see the author’s videos.

What do you need for an induction heater?

- Induction household hob. It is not that expensive and has a power consumption of about 1 kW.

- Radiator. I took the bimetallic one. The number of sections depends on the area you need to heat.

- Metal corrugated hose - can be purchased at any plumbing store. You will need 1.5 meters with a margin.

- Fitting and couplings for connecting the pipe to the radiator.

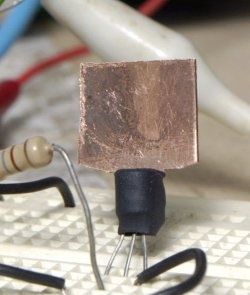

- A piece of copper tube to complete the circuit.

Radiator and tiles:

Any induction cooker has a power control, which can be used to regulate the heating temperature of the radiator.

Corrugated pipe - water supply:

We bend the tube like a snail or a spiral. It bends easily with your hands.The area of the snail circle should be larger than the circular heating surface on the tile.

The main thing is not to forget to make a closing jumper for this circuit, otherwise nothing will work. I made it from a copper tube, soldering it to the beginning and end of the spiral. Now the circuit is closed and all the induction power will be directed into heating.

The induction boiler is ready. In fact, it consists of a purchased induction cooker and a made spiral through which water will be passed.

We screw the circuit to the battery.

We place a tile under the curl.

Pour water into the radiator. When heated, it will circulate in the system itself; in this case, an additional pump is not required.

Turn it on and check. First, set the minimum power on the stove, and then, if necessary, to the maximum.

On expensive models, you can immediately set the heating temperature and the tile itself will maintain it.

I calculated the approximate efficiency of an induction heater compared to a heater using heating elements. And it turned out that the efficiency of an induction heater is 3.5 times higher than that of a heating element heater.

Watch the video

For more detailed experiments and system upgrades, see the author’s videos.

Assembly of the boiler itself.

Choosing an induction cooker. Finalization.

Automation connection.

Testing in a water heating system.

Similar master classes

Particularly interesting

Comments (110)