How to make a cheap swivel TV bracket

A TV bracket is not cheap, so it makes sense to make it yourself. Since it is located behind the screen and is completely invisible, its appearance does not matter at all. This allows you not to bother with the selection of materials, and when assembling it, use the most affordable cheap parts that are sold in any hardware store.

When purchasing materials, you need to pay special attention to the mounting angles. They must be made of thick steel plate with a cross-section of at least 2 mm. In addition, a stiffening rib is required at the corners. Their size is selected individually depending on the weight of the TV, but it is important that they are as wide as possible, at least 65 mm, and preferably 100 mm.

The DIN rail is cut to the required length, guided by the mounting holes for the bracket on the TV body.A perforated corner is screwed into its center. Given the shape of the rail, it will have to be placed on the TV side. After this, the edges of the rail need to be bent, since due to the corner it will not be able to fit closely to the mounting holes, and fasten it with screws. In this case, the corner should be positioned with a downward bend.

The second corner is securely fixed to the wall with an upward bend.

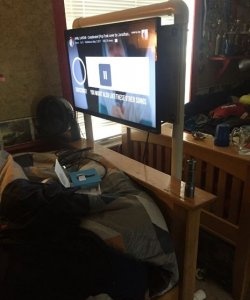

After that, it fits into the corner on the DIN rail with the already installed TV. Everything is tightened with one bolt to be able to rotate the screen to the desired viewing angle. For reliability, it is better to screw 2 nuts onto the bolt, which will prevent the thread from breaking and loosening from numerous turns of the screen.

If the TV is located in a place where the bracket is visible when viewed from the side, then painting will be required. Naturally, in this case, the tested bracket must be removed. It is best to use spray paint that matches the color of the TV.

Manufacturing such a bracket will cost almost 10 times less than a purchased one. At the same time, it allows you to rotate the screen, which only fairly expensive factory brackets are capable of. To save money, if the fastening is not visible at all, you don’t even have to paint it; anyway, the corners and DIN rail are galvanized, so they won’t rust.

Materials:

- mounting perforated corners with stiffening rib - 2 pcs.;

- screws, nuts, washers M6;

- DIN rail;

- dye.

When purchasing materials, you need to pay special attention to the mounting angles. They must be made of thick steel plate with a cross-section of at least 2 mm. In addition, a stiffening rib is required at the corners. Their size is selected individually depending on the weight of the TV, but it is important that they are as wide as possible, at least 65 mm, and preferably 100 mm.

Assembling the bracket and installing the TV

The DIN rail is cut to the required length, guided by the mounting holes for the bracket on the TV body.A perforated corner is screwed into its center. Given the shape of the rail, it will have to be placed on the TV side. After this, the edges of the rail need to be bent, since due to the corner it will not be able to fit closely to the mounting holes, and fasten it with screws. In this case, the corner should be positioned with a downward bend.

The second corner is securely fixed to the wall with an upward bend.

After that, it fits into the corner on the DIN rail with the already installed TV. Everything is tightened with one bolt to be able to rotate the screen to the desired viewing angle. For reliability, it is better to screw 2 nuts onto the bolt, which will prevent the thread from breaking and loosening from numerous turns of the screen.

If the TV is located in a place where the bracket is visible when viewed from the side, then painting will be required. Naturally, in this case, the tested bracket must be removed. It is best to use spray paint that matches the color of the TV.

Manufacturing such a bracket will cost almost 10 times less than a purchased one. At the same time, it allows you to rotate the screen, which only fairly expensive factory brackets are capable of. To save money, if the fastening is not visible at all, you don’t even have to paint it; anyway, the corners and DIN rail are galvanized, so they won’t rust.

Watch the video

Similar master classes

Particularly interesting

Comments (5)