How to make rubber coating of metal

Rubber coating allows you to make any hard surface non-slip, warmer and more pleasant to the touch. To carry it out, various technologies are used that require the use of special equipment and materials. This is unacceptable for rubberizing at home. Let's consider an extremely simple technology that allows you to rubberize a surface with your own hands with a minimum of effort.

The surface for rubber coating must be degreased with a solvent. If this is a metal prone to rust, then it must also be primed so that corrosion does not begin on it under the rubber from contact with the components of the sealant.

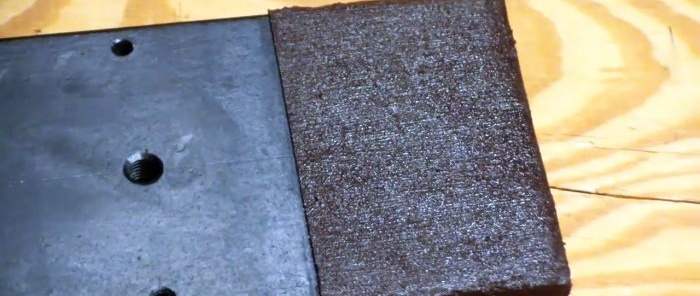

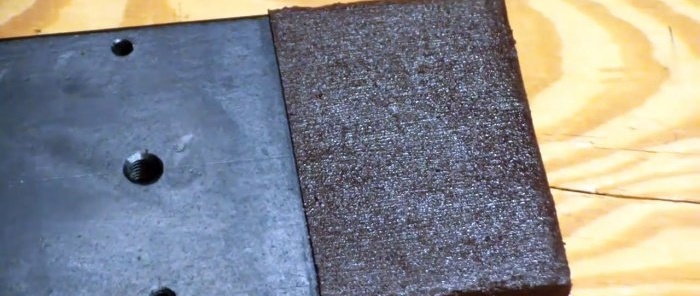

After degreasing, a fiberglass mesh is glued to the surface. If you need to rubberize the ends and sides of an object, then the serpyanka is glued with an inflection and on them. It is advisable to apply 2 layers of mesh so that the thickness of the rubber coating is at least 1 mm.

If the rubber coating is carried out partially, then masking tape is glued along its border. Regular tape will work, but it leaves sticky marks on many surfaces.

Next, sealant is applied to the mesh. It can be silicone, polyurethane, acrylic or any other. The choice of sealant depends only on the desired performance qualities of the rubberized layer that need to be obtained.

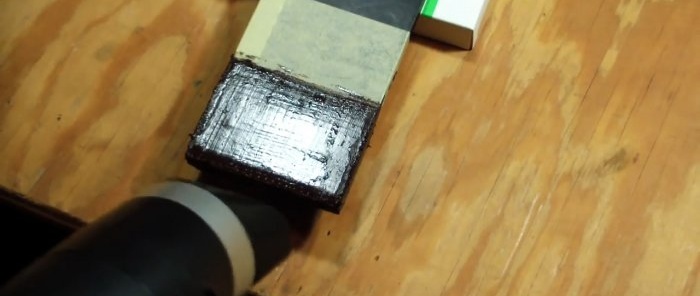

Using a spatula or plastic card, rub the composition into the mesh until all cells are filled. After this, the sealant is dried with a hairdryer.

As soon as a dried crust appears on the sealant, a second layer is applied.

It is also smoothed and dried with a hairdryer.

This time less composition will be needed, only to partially smooth out the depressions in the mesh cells.

To finally remove any unevenness and create a matte surface, a third thin layer of sealant is applied.

It is smoothed in one direction with a dishwashing sponge.

After leveling the sealant, you need to give it a matte finish. It is created by light tangential movements of the sponge.

Next you need to pause until the sealant has completely dried. If silicone is used, its polymerization ends after 24 hours. Then, using a blade or a mounting knife, you need to cut through the rubberized layer along the line of the masking tape and tear it off.

Rubber coating using a painting fiberglass mesh allows you to accurately control the thickness of the sealant layer. Serpyanka reinforces the coating, increases its strength and resistance to friction. This method can be used to coat metal, wood and other materials that are compatible with the type of sealant used.

Materials:

- self-adhesive serpyanka mesh;

- masking tape;

- sealant;

- solvent.

How to rubberize metal

The surface for rubber coating must be degreased with a solvent. If this is a metal prone to rust, then it must also be primed so that corrosion does not begin on it under the rubber from contact with the components of the sealant.

After degreasing, a fiberglass mesh is glued to the surface. If you need to rubberize the ends and sides of an object, then the serpyanka is glued with an inflection and on them. It is advisable to apply 2 layers of mesh so that the thickness of the rubber coating is at least 1 mm.

If the rubber coating is carried out partially, then masking tape is glued along its border. Regular tape will work, but it leaves sticky marks on many surfaces.

Next, sealant is applied to the mesh. It can be silicone, polyurethane, acrylic or any other. The choice of sealant depends only on the desired performance qualities of the rubberized layer that need to be obtained.

Using a spatula or plastic card, rub the composition into the mesh until all cells are filled. After this, the sealant is dried with a hairdryer.

As soon as a dried crust appears on the sealant, a second layer is applied.

It is also smoothed and dried with a hairdryer.

This time less composition will be needed, only to partially smooth out the depressions in the mesh cells.

To finally remove any unevenness and create a matte surface, a third thin layer of sealant is applied.

It is smoothed in one direction with a dishwashing sponge.

After leveling the sealant, you need to give it a matte finish. It is created by light tangential movements of the sponge.

Next you need to pause until the sealant has completely dried. If silicone is used, its polymerization ends after 24 hours. Then, using a blade or a mounting knife, you need to cut through the rubberized layer along the line of the masking tape and tear it off.

Rubber coating using a painting fiberglass mesh allows you to accurately control the thickness of the sealant layer. Serpyanka reinforces the coating, increases its strength and resistance to friction. This method can be used to coat metal, wood and other materials that are compatible with the type of sealant used.

Watch the video

Similar master classes

Particularly interesting

Comments (3)