How to make a container for flowers from pallets

During the period of self-isolation, one has to adhere to austerity regime, so in this project I used material that was left over during the construction process.

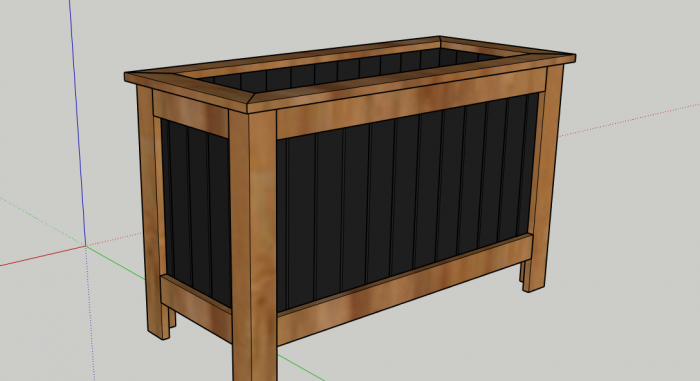

I drew a 3D model in SketchUp (I am attaching a link to the model) to roughly understand how much material I will need.

I started dismantling the pallets and removing nails from them.

To make the nails come out easier, I carried out one manipulation in the form of a couple of strong presses on the corners of the pallet.

After disassembly, I removed all the nails from the boards and went to plan them.

I planed two sides on the jointer for a right angle.

To begin with, I prepared the first batch of boards that were intended for lining the container. The width of the boards for covering is 80 mm.

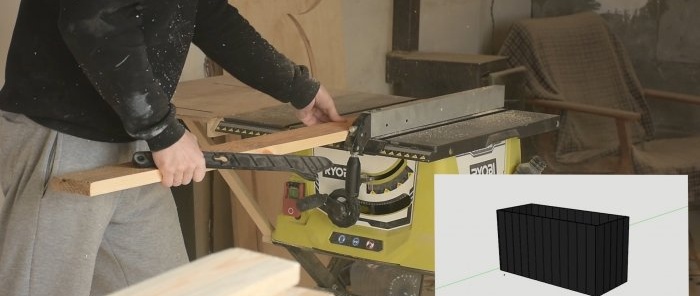

And I cut this batch on a carriage into a size of 500 mm.

I unravel the second batch of boards for the frame of the container. The width of the boards is 70 mm.

And I also cut all the parts on the carriage to size.

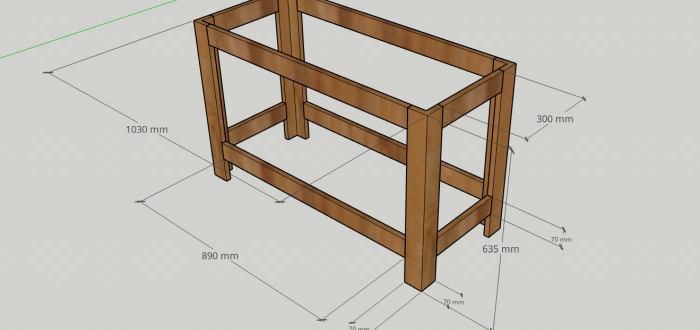

Container frame dimensions.

After cutting all the parts, I used a router to chamfer at 45 degrees on all the front faces of the container elements.

I assembled the frame of the container using an “oblique screw” connection (below is a picture of this connection) with the addition of “Moment carpentry” glue.

4 legs were also pulled together with an oblique screw. The leg was made of two parts, the first part is 635 mm x 70 mm, the second part is 635 mm x 50 mm. The thickness of the boards is 20 mm, so the end result is a flat corner with sides of 70 mm x 70 mm x 635 mm.

The result of the frame assembly.

Having previously sanded the sheathing, I began installing it. I used screws and wood glue.

The result with the sheathing.

For the bottom of the container I used an OSB sheet and to strengthen its fastening I added a birch block along the perimeter on which the sheet would rest.

Having cut the OSB sheet to size, I place it on the bars and fasten it with self-tapping screws.

For the trim on top of the container I used 18mm plywood. The strip width is 80 mm.

The connection of the platbands was made at 45 degrees. I also chamfered all the edges of the platbands.

I screwed the trims onto the same oblique screw and wood glue.

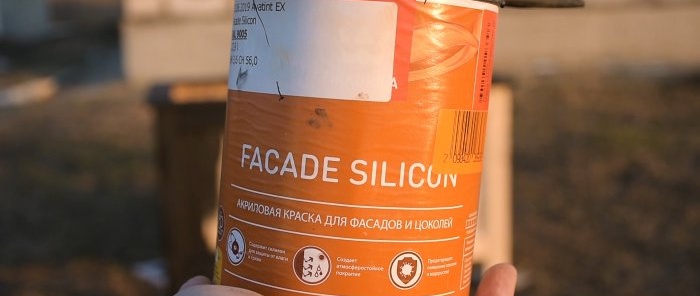

All that remains is to coat the product with moisture-resistant paint.

I used this façade acrylic paint.

And you're done!

The detailed manufacturing process can be seen in the video below.

Thank you for your attention!

Namely:

- - a couple of pallets.

- - remains of OSB sheet.

- - several strips of 18 mm plywood (although material from pallets could be used).

- - 32 mm self-tapping screws, Moment carpentry glue and moisture-resistant paint.

Stage one (3D model)

I drew a 3D model in SketchUp (I am attaching a link to the model) to roughly understand how much material I will need.

Stage two (material preparation)

I started dismantling the pallets and removing nails from them.

To make the nails come out easier, I carried out one manipulation in the form of a couple of strong presses on the corners of the pallet.

After disassembly, I removed all the nails from the boards and went to plan them.

I planed two sides on the jointer for a right angle.

To begin with, I prepared the first batch of boards that were intended for lining the container. The width of the boards for covering is 80 mm.

And I cut this batch on a carriage into a size of 500 mm.

I unravel the second batch of boards for the frame of the container. The width of the boards is 70 mm.

And I also cut all the parts on the carriage to size.

Container frame dimensions.

After cutting all the parts, I used a router to chamfer at 45 degrees on all the front faces of the container elements.

Stage three (container assembly)

I assembled the frame of the container using an “oblique screw” connection (below is a picture of this connection) with the addition of “Moment carpentry” glue.

4 legs were also pulled together with an oblique screw. The leg was made of two parts, the first part is 635 mm x 70 mm, the second part is 635 mm x 50 mm. The thickness of the boards is 20 mm, so the end result is a flat corner with sides of 70 mm x 70 mm x 635 mm.

The result of the frame assembly.

Having previously sanded the sheathing, I began installing it. I used screws and wood glue.

The result with the sheathing.

For the bottom of the container I used an OSB sheet and to strengthen its fastening I added a birch block along the perimeter on which the sheet would rest.

Having cut the OSB sheet to size, I place it on the bars and fasten it with self-tapping screws.

For the trim on top of the container I used 18mm plywood. The strip width is 80 mm.

The connection of the platbands was made at 45 degrees. I also chamfered all the edges of the platbands.

I screwed the trims onto the same oblique screw and wood glue.

All that remains is to coat the product with moisture-resistant paint.

I used this façade acrylic paint.

And you're done!

The detailed manufacturing process can be seen in the video below.

Thank you for your attention!

Watch the video

Similar master classes

Particularly interesting

Comments (2)