How to make cheap active ventilation in a garage or workshop

In a closed workshop or garage, you can get sick from smoke when working with welding or an angle grinder. To remove it from the room, powerful exhaust ventilation is needed. It can be assembled from sewer pipes and a duct fan.

Materials:

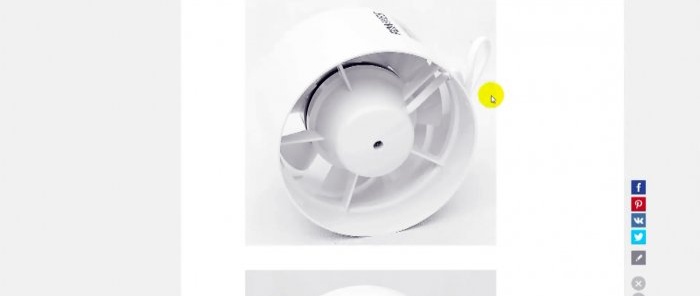

- duct fan 100 mm;

- sewer pipe 110 mm;

- pipe mounting clamps;

- 90 degree elbow;

- stub;

- two-wire electrical wire;

- key switch.

Ventilation assembly process

A hole is made in the wall under the ceiling to match the diameter of the pipe. A short sewer pipe is inserted into it and connected to the elbow from the outside. A vertical pipe is connected to the elbow and covered with a canopy against precipitation. The higher it gets, the better it will be for air and smoke to escape naturally without turning on the fan.

The pipes are attached to the walls and ceiling using clamps.

A 100 mm duct fan is inserted into a short pipe from the inside. You can also use 125 mm, but then you will need an adapter.

The fan is secured in the pipe using a rubber seal or a self-tapping screw. It is supplied with power via a key switch.

A long pipe is attached to the fan pipe. She needs to be brought to her workplace. It is drilled with a large drill in several rows. Its edge is closed with a plug.

When the fan is turned on, air will be drawn evenly along the entire length of the pipe through the holes. This solution is more compact and cheaper than installing an exhaust hood, which usually interferes with normal work in the workshop.

Watch the video

Similar master classes

Particularly interesting

Comments (1)