How to make your own cheap penetrating lubricant

WD-40 penetrating fluid is very popular, but it has become very expensive in recent years. If you have to use this lubricant often, then it costs a lot of money. To save money, you can make an analogue of WD-40, and no worse than the original.

The first thing you need to take care of is the aerosol container. To do this, you will need to repurpose an old empty WD-40 canister.

It is necessary to cut the nipple out of the chamber, leaving a little rubber around it.

An 8 mm hole is drilled in the prepared clamp. Burrs are removed with a file. A nipple is inserted into the clamp from the inside.

In an empty WD-40 canister, you need to punch a hole right in the center of the number “0” in the inscription indicating the volume.

The paint around it is cleaned off, the area is degreased, as is the rubber on the nipple.

Then glue is applied. The nipple is glued onto the cylinder and the clamp is immediately tightened.

Next, the analogue of WD-40 itself is prepared. To do this, add 1 part machine oil to 3 parts kerosene or white spirit. The mixture is poured into the container through the nipple with a syringe.To do this you will have to unscrew the spool.

Then air is pumped into the balloon to 2-3 atm.

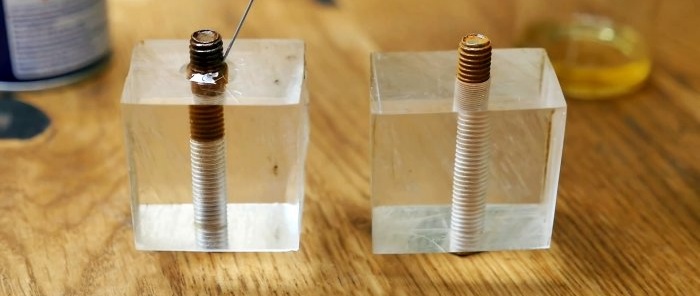

The result is a ready-to-use penetrating liquid that helps unscrew rusted threads, lubricate them and displace moisture.

Our analogue turned out no worse than the original lubricant.

Materials:

- nipple;

- power clamp 52-55 mm;

- WD-40 bottle;

- universal glue;

- kerosene or white spirit;

- machine oil.

The process of making an aerosol analogue of WD-40

The first thing you need to take care of is the aerosol container. To do this, you will need to repurpose an old empty WD-40 canister.

It is necessary to cut the nipple out of the chamber, leaving a little rubber around it.

An 8 mm hole is drilled in the prepared clamp. Burrs are removed with a file. A nipple is inserted into the clamp from the inside.

In an empty WD-40 canister, you need to punch a hole right in the center of the number “0” in the inscription indicating the volume.

The paint around it is cleaned off, the area is degreased, as is the rubber on the nipple.

Then glue is applied. The nipple is glued onto the cylinder and the clamp is immediately tightened.

Next, the analogue of WD-40 itself is prepared. To do this, add 1 part machine oil to 3 parts kerosene or white spirit. The mixture is poured into the container through the nipple with a syringe.To do this you will have to unscrew the spool.

Then air is pumped into the balloon to 2-3 atm.

The result is a ready-to-use penetrating liquid that helps unscrew rusted threads, lubricate them and displace moisture.

Our analogue turned out no worse than the original lubricant.

Watch the video

Similar master classes

Particularly interesting

Comments (0)