How to make an original handle from PET bottle caps

By melting waste from HDPE plastic you can make various crafts. By mixing raw materials of different colors, products from them are obtained with beautiful stains. To understand the basics of plastic processing, try your hand at making ballpoint pen bodies from it.

Materials:

- HDPE plastic waste: caps from PET bottles, scraps of bottles and canisters;

- wood scraps;

- set for making ballpoint pens.

Handle making process

It is necessary to shred and mix various plastic wastes labeled as HDPE. These could be caps from PET bottles, bottles from shampoo, detergent, or canisters. An electric grill or multi-maker is great for melting. To avoid spoiling it, the mold should be lined with parchment paper smeared with silicone grease.

To obtain a blank for the handle body, it is necessary to assemble a mold. Any wooden scraps will do for this. The mold should form a groove into which a strip will be inserted, pressing and compacting the plastic mass.

Silicone paper is placed in the grill and plastic is applied. After softening, it is taken out, along with the parchment, and crushed into a single mass. This will require very thick gloves. Stir the mixture until the plastic is mixed. You will need to return it to the grill a couple of times and warm it up. Twisting gives beautiful stains, so it must be done at the end.

The mixed mass is placed in a mold, closed with a lath and compressed with a clamp or vice.

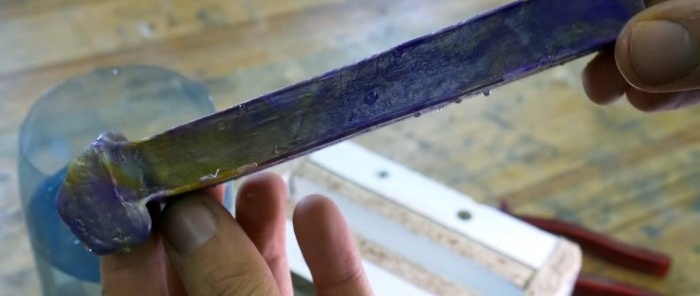

After 10 minutes, the workpiece hardens enough to be pulled out. If it is still hot, you can cool it quickly in water.

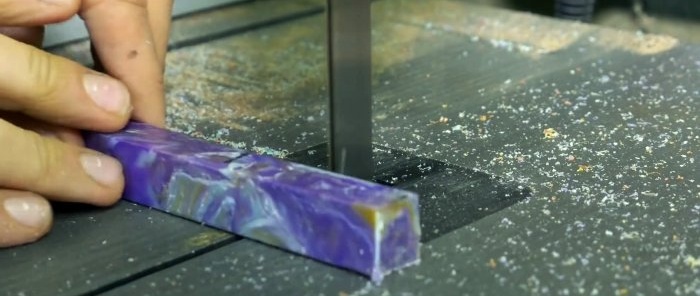

The workpiece is trimmed from defects and cut in half.

Then the halves need to be drilled lengthwise with a thin drill and brass tubes pressed into the holes.

Next comes the turning work. To process both parts at once, you should clamp a rod into the machine chuck and put the parts on it, alternating them with bushings from the same tube. There must be a thread at the end of the rod to tighten the workpiece with a nut. Next they are sharpened.

During work, chips and torn areas may form. The broken part should be heated with a hair dryer until it melts, and simply rub it into the damage. After the plastic has hardened, you can continue stitching.

The resulting tubes after the cutters are finished with files and fine-grained sandpaper. Finishing is done with polishing paste.

The part includes a tip, cap, refill and ring from a purchased kit for making a ballpoint pen. As a result, we get a very worthy accessory for a gift or for yourself.

Watch the video

Similar master classes

Particularly interesting

Comments (0)