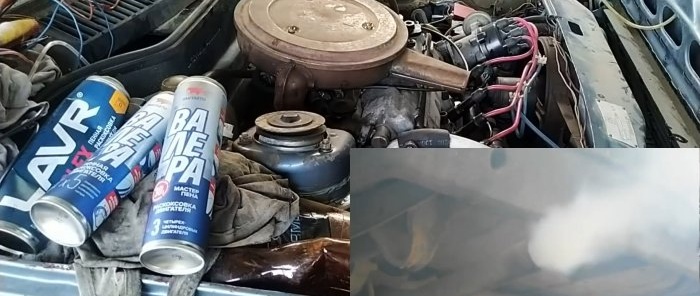

Experiment: engine decarbonization without disassembly using Lavr and Valera foams

Carbon deposits accumulate inside the engine cylinder and on the pistons, interfering with the operation of the lubrication system. As its quantity increases, significant oil consumption occurs. At the initial stages, this problem is solved by decoking without disassembly. Let's look at the example of using two foams for decarbonization LAUR and VALERA, what this gives.

What you will need:

- USB endoscope - http://alii.pub/5nilun

- Non-contact thermometer - http://alii.pub/5nilvf

- decoking foam;

- large syringe;

- thin hose;

- new oil;

- oil filter.

Engine decarbonization process

A visual inspection of the cylinders will be performed using a videoscope.

Let's check the compression.

Decarbonization is performed with the engine warmed up to +50°C and turned off. It is necessary to unscrew the spark plugs, shake the foam and blow into the cylinder until it comes out. The candle is then baited back to create a steam bath effect inside.

For the purpose of the experiment, the first 2 cylinders are treated with VALERA foam, and the rest LAUR, in order to understand for the future which of them copes better. After a while, the cylinders foam again.According to the instructions, VALERA is filled 5 times with an interval of 5-7 minutes, and LAUR 2 times with a pause of 25 minutes.

For clarity of the experiment, in order to understand what is happening in the engine, both products are used on dismantled pistons with equally coked oil scraper and compression rings. They are heated to operating temperature, foamed and sealed in jars.

As a result of the experiment with dismantled pistons, both products worked, but LAVR cleaned the grooves and rings better. Naturally, such an effect cannot be achieved in an engine, since it will not be possible to wipe off the softened carbon deposits in the cylinder with a rag.

The remaining foam that has turned into liquid is removed from the cylinders with a syringe with a tube on the spout. Even at the application stage, it was clear that VALERA foam dropped in volume instantly, so it cleans the top of the cylinders less well in real conditions. Judging by the liquid residue of LAUREL in the cylinder there is more. It actually took one cylinder, and the second one and a half foam. From the experiment it is clear that none of the products used will clean 4 cylinders of a small car with one cylinder.

After decoking, you need to change the oil and oil filter. Immediately after starting, the car will smoke due to residual foam and removed liquid. According to the results of the experiment, decoking caused a drop in compression in each cylinder, and in one cylinder by 3 times, so the feasibility of its implementation on old engines is questionable. As a preventative measure on almost clean engines when changing the oil, this is more justified.

Watch the video

Similar master classes