Powerful F-shaped clamp from old valves

Just a vice in the workshop may not be enough. It is convenient to fix large workpieces with a clamp. You can make it from unnecessary valves and strip scraps.

Materials:

- automobile valves – 2 pcs.;

- strip 30x2 mm;

- M20 pin;

- nut M20;

- square 10x10 mm.

Clamp manufacturing process

To make a movable jaw for clamping a clamp, you need to cut off the valve stem, leaving approximately 10 mm. Its remainder on the plate is ground into a ball.

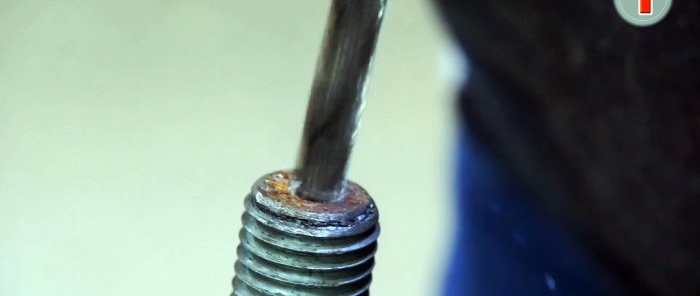

Next, the end of the M20 pin is drilled so that the ball at the end of the valve fits freely into the resulting hole.

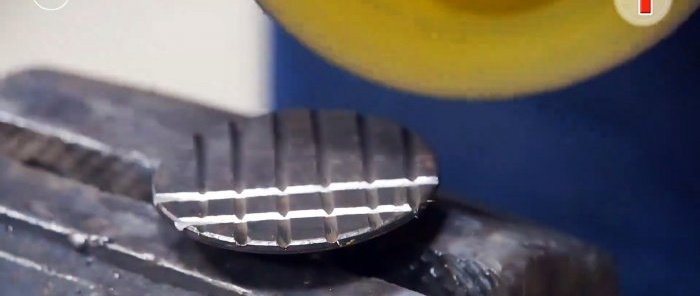

Anti-slip notches are cut on its plate.

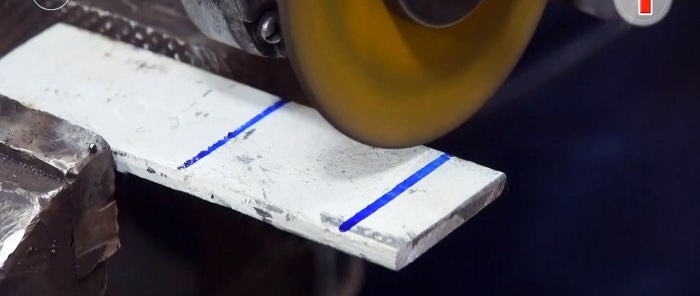

It is necessary to weld a sliding lower jaw holder from strip sections. It will slide on a frame made of the same strip.

A second valve with a shortened rod and notches on the plate is welded to it.

The upper holder is made of a square, to the end of which an M20 nut is welded. It is welded to the base of the strip clamp. A pin is screwed into the nut. A sliding bracket with a second jaw is placed on the base.

The hairpin is shortened and equipped with a collar. Next, you need to movably secure the valve with the ball in it.To do this, it is drilled from the side, and a ball from the bearing is welded into the hole. Thanks to this, the pressure angle of the sponge will be adjusted.

The resulting clamp has a large grip; it can be clamped and removed fairly quickly.

It can be used both when working in carpentry and metalworking workshops.