Tin can blower

A blower made from a tin can - small but remote! Any master knows how important order is in the workshop. But cleaning this room clean is sometimes not such an easy task. This is especially true for hard-to-reach places - tile joints, shelves, racks, lamps, etc. Regular brooms and brooms will do just fine. But today we want to offer a special tool for solving such problems.

The blower made by the author of the video emphasizes that originality can be found in everything, even in cleaning products. And despite the fact that there are already many sweeping brushes, air spray guns and brooms, someone comes up with such a unique homemade product.

Materials:

Tools:

To begin, take a wide tin can and use a screwdriver to make a hole in the side of it using a feather drill with a diameter of 20-22 mm.

In the bottom of the same can we make a small hole for the motor shaft. This can be done with a regular drill or use a turbine (there will be fewer burrs). Having tried the engine in place, we mark two side holes for the mounting bolts for it. The hardware is small, so we make holes for them with a 2.5-3 mm drill.

We make the guide tube from a tall narrow can. We cut the bottom and collar with metal scissors. Then we take any round rod and twist a tube of small thickness, which we give into the shape of a cone.

We clean the joint of the two edges of the sheet metal with an amalgam abrasive. This must be done for a quality connection. To keep the tin in shape, we put a rubber tie on the edge of the tube. We take a soldering iron and use flux to solder the entire joint.

We mark the cut of the tube at an angle to the circumference of the jar, like a watering can. We cut the collar of the tube with scissors.

Place the base of the tube against the hole in the can and solder it with a soldering iron. The solder must go all the way through the gate for the connection to be reliable. Our body should look like this (photo).

From the next wide, smaller jar, cut out the bottom and side wall. From the resulting ribbon we cut six small petals.

The bottom should fit freely into the inside of the body (large can), without touching its side walls. We make a hole in the center with a drill or awl, and divide the circle into six equal parts. To do this, you can use a protractor, marking 60 and 120 degrees from the center line.

We mark the lines with notches using metal scissors. We clean the markings with abrasive along the entire length of the solder. We do the same with the petals.

Slightly bending the petals in an arc, place them one after the other and solder them to the lid with a soldering iron. The center of the impeller should remain intact.

To transmit torque from the engine to the impeller, we use a plastic gear. For it, we expand the hole with a drill of suitable diameter. Epoxy glue will help secure it.

After the epoxy has dried, we assemble the main part of the device. We fix the engine with self-tapping screws, and then we attach the impeller.

In the third wide jar, use a furniture cutter to select the middle at the bottom. We cut off the excess so that one cover remains, suitable as a plug for the body.

We slightly bend the edges of the cover with pliers and insert it into place in the body. We fix the connection of the plug for reliability in several places with a soldering iron.

The electrical circuit of this homemade product is simple. It involves a battery, which has two output contacts for supplying electricity to the device (motor), and two incoming contacts for recharging. We solder two wires to the engine with a connector for the battery contacts, and connect these two elements. The intermediate link in the chain is the button. We place the switch button on the side surface of the case and glue it with hot glue. We also secure the batteries.

The device is ready, now charge the batteries via the adapter and test it in action.

Such a simple thing is capable of blowing air quite powerfully, sweeping away debris from machines, a work table, or a surface necessary for work. Of course, this is not a complete solution for cleaning the workshop, and sooner or later everything unnecessary will have to be thrown into the trash. But when it comes to saving time and the compressor is busy, such a blower will come in handy. Good luck to everyone and bye!

The blower made by the author of the video emphasizes that originality can be found in everything, even in cleaning products. And despite the fact that there are already many sweeping brushes, air spray guns and brooms, someone comes up with such a unique homemade product.

Required resources to assemble the miracle leaf blower

Materials:

- Five tin cans - three flat, two tall;

- Motor, type 775;

- Two lithium polymer or similar batteries with a contact group;

- Button switch with wires;

- Several plastic gears to match the size of the motor shaft.

Tools:

- Screwdriver;

- Set of regular and feather drills;

- Metal scissors;

- Regular scissors;

- Soldering iron with flux and solder;

- Impeller with abrasive and cutting disc for metal;

- Glue gun;

- Adapter for charging batteries.

- Screwdriver, pliers, knife.

Assembling a blower with your own hands

Stage one - we make a body with a guide tube

To begin, take a wide tin can and use a screwdriver to make a hole in the side of it using a feather drill with a diameter of 20-22 mm.

In the bottom of the same can we make a small hole for the motor shaft. This can be done with a regular drill or use a turbine (there will be fewer burrs). Having tried the engine in place, we mark two side holes for the mounting bolts for it. The hardware is small, so we make holes for them with a 2.5-3 mm drill.

We make the guide tube from a tall narrow can. We cut the bottom and collar with metal scissors. Then we take any round rod and twist a tube of small thickness, which we give into the shape of a cone.

We clean the joint of the two edges of the sheet metal with an amalgam abrasive. This must be done for a quality connection. To keep the tin in shape, we put a rubber tie on the edge of the tube. We take a soldering iron and use flux to solder the entire joint.

We mark the cut of the tube at an angle to the circumference of the jar, like a watering can. We cut the collar of the tube with scissors.

Place the base of the tube against the hole in the can and solder it with a soldering iron. The solder must go all the way through the gate for the connection to be reliable. Our body should look like this (photo).

Stage two - making the impeller

From the next wide, smaller jar, cut out the bottom and side wall. From the resulting ribbon we cut six small petals.

The bottom should fit freely into the inside of the body (large can), without touching its side walls. We make a hole in the center with a drill or awl, and divide the circle into six equal parts. To do this, you can use a protractor, marking 60 and 120 degrees from the center line.

We mark the lines with notches using metal scissors. We clean the markings with abrasive along the entire length of the solder. We do the same with the petals.

Slightly bending the petals in an arc, place them one after the other and solder them to the lid with a soldering iron. The center of the impeller should remain intact.

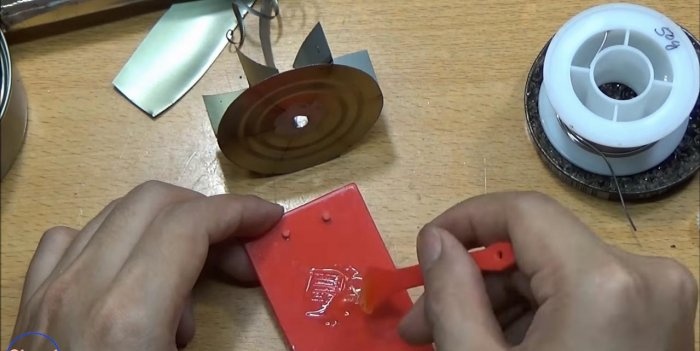

To transmit torque from the engine to the impeller, we use a plastic gear. For it, we expand the hole with a drill of suitable diameter. Epoxy glue will help secure it.

After the epoxy has dried, we assemble the main part of the device. We fix the engine with self-tapping screws, and then we attach the impeller.

Stage three - outer cover and electrical

In the third wide jar, use a furniture cutter to select the middle at the bottom. We cut off the excess so that one cover remains, suitable as a plug for the body.

We slightly bend the edges of the cover with pliers and insert it into place in the body. We fix the connection of the plug for reliability in several places with a soldering iron.

The electrical circuit of this homemade product is simple. It involves a battery, which has two output contacts for supplying electricity to the device (motor), and two incoming contacts for recharging. We solder two wires to the engine with a connector for the battery contacts, and connect these two elements. The intermediate link in the chain is the button. We place the switch button on the side surface of the case and glue it with hot glue. We also secure the batteries.

The device is ready, now charge the batteries via the adapter and test it in action.

Conclusion

Such a simple thing is capable of blowing air quite powerfully, sweeping away debris from machines, a work table, or a surface necessary for work. Of course, this is not a complete solution for cleaning the workshop, and sooner or later everything unnecessary will have to be thrown into the trash. But when it comes to saving time and the compressor is busy, such a blower will come in handy. Good luck to everyone and bye!

Watch the video

Similar master classes

Particularly interesting

Comments (1)