5 simple but very useful ideas for the home handyman

Often we have to contrive to solve a technical problem without resorting to an expensive or one-time purchased tool. We offer a selection of 5 simple ideas. It contains useful solutions that will allow you to deal with them immediately when such problems arise, rather than thinking about how to get out of the situation.

1. Cutting tiles with a nail

If you don't have a tile cutter, you can sharpen the tip of the nail. Using it, we scratch the tile from the back side to leave a deep groove.

Then we break the tile along the line, placing the same nail under it. In general, we do the same thing as when cutting glass.

As a result, the tile will break along the line. If the glaze on the front has visible chips, then you can sand the edge.

2. Fastening to hollow walls

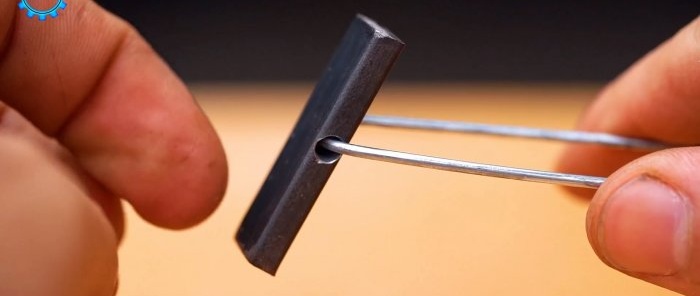

If you need to fasten something to a hollow wall in which conventional fasteners do not hold, then you need to drill a hole in it and select a piece of metal strip based on its width. It should fit into the hole. Then we drill a strip across the center.

A wire is threaded through the hole in the strip and bent.We insert the plate into the hole in the wall, holding it by the wire. As a result, the strip will unfold, and it will no longer be possible to pull it out.

Now you can screw what you need to this wire.

3. Wire crochet hook

It takes a lot of effort to wind stiff wire neatly. It is much easier to do this with a hook. To make it, you need to take a rod with a diameter of 6-8 mm and drill 2 holes at its end slightly larger than the cross-section of the wire.

For convenience, a wooden handle is installed on the rod. Now you can insert the edge of the wire into the holes.

Using a hook, you can pull the wire like a lever and wind it tightly, literally tightening it like a clamp.

4. Fastening with self-tapping screws in laminated chipboard

Wood screws are not able to be securely held in chipboard. Therefore, you need to drill at their location and glue in the mortgages from wooden dowels. The screws fit in them very securely.

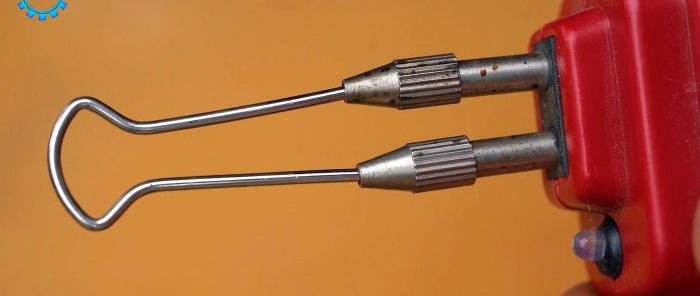

5. Soldering iron for repairing plastic

If you have a pulse soldering iron, then you can make a tip for it by cutting off the bow of a stationery binder.

It is inserted into a soldering iron, and after heating it perfectly melts and smoothes out defects on plastic, such as cracks and chips.