How to make an electric grill spit from a windshield wiper motor

To grill a whole carcass on the grill, you need to turn it often or even continuously. This way nothing will burn and it definitely won’t remain raw on one side. In order not to twirl a skewer near a hot grill, you can make an electric spit.

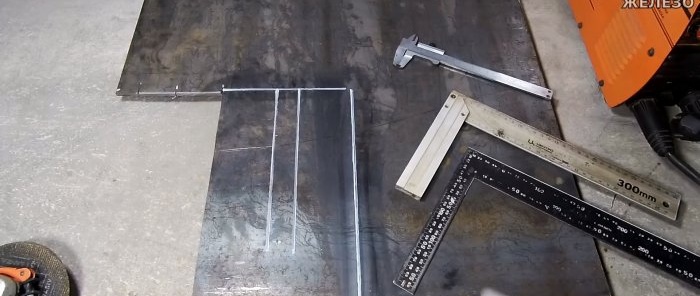

First you need to make a mount for the gearbox. To do this, you will need a piece of sheet steel 100x70 mm. In it, in the center, drill a large hole with a crown for the gearbox shaft and 3 ordinary ones for fastening it. Then the blanks are cut out: 60x75 mm and 3 pcs. 60x30 mm. On the large one and one small one you need to trim the corners.

For the second part required to stop the skewer, you need to cut blanks 60x50 mm, and 2 - 20x50 mm. A hole is drilled from the edge of the large one. Corners are cut off on small ones.

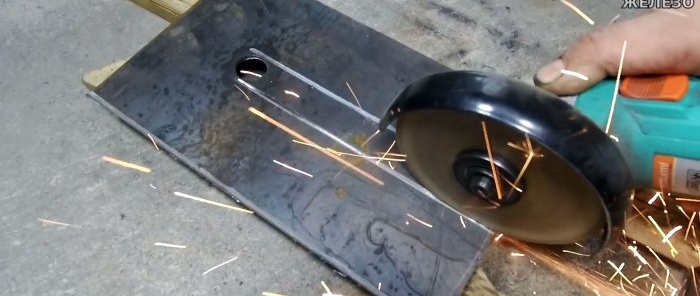

Next, the console racks are made. 2 large blanks 300x180 mm are cut out. A wide cutout is made along them in the center.To hook the racks you need to prepare 4 parts 125x30 mm.

After fitting the parts, they are welded.

The first mount for the geared motor is made as in the photo. A hole is drilled in it to the side and an M10 thread is cut. The second part is also welded and also equipped with a threaded hole.

Mounting plates with cutouts on the sides are welded to the racks. Near each of them you will need to make a hole and cut an M10 thread. As a result, the gearbox mount and the second part should slide freely along the cutout in the racks. On the reverse side they are locked by screwing in bolts.

Next, you need to make a fastening to the gearbox shaft from a machined extended M6 nut. The resulting coupling is welded with an M10 nut. They are then welded to the kitchen rail. A sharp tip is made at the second end of the tube.

From an old skewer and 2 pieces of pipe you need to make forks to fix the carcass on the rail, preventing it from slipping. Side holes are drilled into them, to which nuts are welded. This will allow them to be clamped onto the railing.

The racks are put on the grill and clamped.

Then fastenings are placed on them.

The carcass is strung on a rail and secured with forks at the edges.

This skewer is then screwed into the gear motor shaft. The engine itself is connected to a battery or power supply.

Materials:

- gear motor from wipers;

- thick sheet metal;

- kitchen railing;

- M10 bolts;

- old skewer.

The manufacturing process of an electric drive console

First you need to make a mount for the gearbox. To do this, you will need a piece of sheet steel 100x70 mm. In it, in the center, drill a large hole with a crown for the gearbox shaft and 3 ordinary ones for fastening it. Then the blanks are cut out: 60x75 mm and 3 pcs. 60x30 mm. On the large one and one small one you need to trim the corners.

For the second part required to stop the skewer, you need to cut blanks 60x50 mm, and 2 - 20x50 mm. A hole is drilled from the edge of the large one. Corners are cut off on small ones.

Next, the console racks are made. 2 large blanks 300x180 mm are cut out. A wide cutout is made along them in the center.To hook the racks you need to prepare 4 parts 125x30 mm.

After fitting the parts, they are welded.

The first mount for the geared motor is made as in the photo. A hole is drilled in it to the side and an M10 thread is cut. The second part is also welded and also equipped with a threaded hole.

Mounting plates with cutouts on the sides are welded to the racks. Near each of them you will need to make a hole and cut an M10 thread. As a result, the gearbox mount and the second part should slide freely along the cutout in the racks. On the reverse side they are locked by screwing in bolts.

Next, you need to make a fastening to the gearbox shaft from a machined extended M6 nut. The resulting coupling is welded with an M10 nut. They are then welded to the kitchen rail. A sharp tip is made at the second end of the tube.

From an old skewer and 2 pieces of pipe you need to make forks to fix the carcass on the rail, preventing it from slipping. Side holes are drilled into them, to which nuts are welded. This will allow them to be clamped onto the railing.

The racks are put on the grill and clamped.

Then fastenings are placed on them.

The carcass is strung on a rail and secured with forks at the edges.

This skewer is then screwed into the gear motor shaft. The engine itself is connected to a battery or power supply.

Watch the video

Similar master classes

Particularly interesting

Comments (0)