How to assemble a structure for sharpening knives from available materials

Knifes sold in stores, despite their high price, often do not cope with the task, in particular, they do not ensure a constant sharpening angle. You can save your family budget and ensure the quality of sharpening using a homemade sharpening device, and this does not require special knowledge and skills.

Will need

Materials:

- clips for round pipes;

- wooden board 12 cm wide;

- plastic pipes;

- bolt, screws, screws and nuts;

- a piece of steel profile square pipe;

- brand aluminum cut;

- pieces of steel plates;

- half clamps;

- sandpaper on a backing, etc.

Tools: pencil, tape measure, drilling machine, scissors for cutting plastic pipes, drill, etc.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

The process of assembling a structure for sharpening knives from available materials

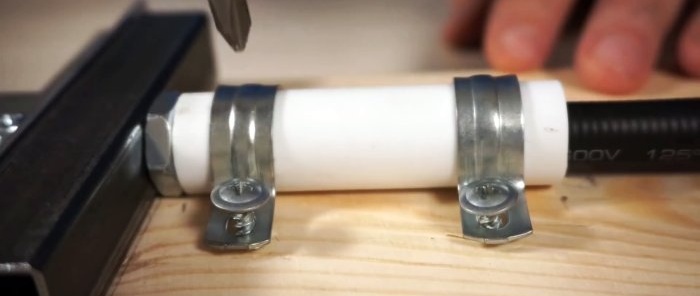

We connect a pair of clips to each other using a screw crosswise. We insert a plastic pipe into one of them and snap the clip into place.

We mark the middle on the board, place the free clip along this mark and mark the center of the plastic pipe. In this place of the board we drill a hole and fix a plastic pipe in it.

We cut two rings from the plastic pipe, make radial drillings in them and tighten the screws. We put one ring on the pipe in the board, then a free clip with a second clip attached to it, fixed to the pipe, and another clip on top. We fix the lower and upper clips on the stand pipe with screws.

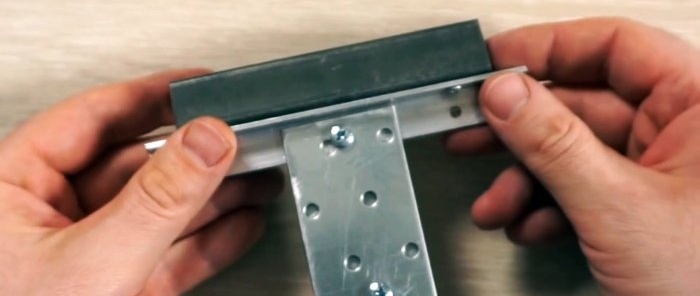

In a piece of profile square pipe on one side, drill a hole in the center. To the opposite side of the pipe we attach an aluminum brand slightly longer than the pipe in the longitudinal direction using rivets.

We attach two plates to the center of the brand with bolts and nuts. We insert a square nut inside the square pipe and push it to the hole in the pipe. From the outside, screw a bolt with a screwed nut into the nut.

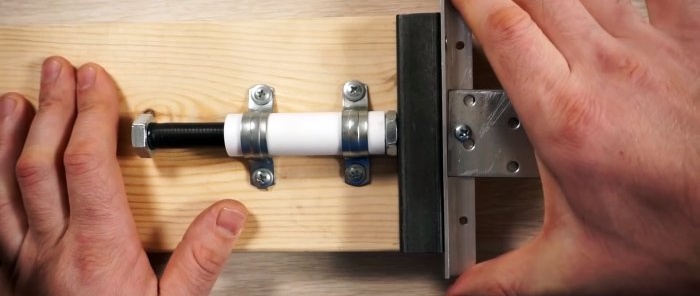

In advance, cover the rod between the nut and the bolt head with a thin tube made of slippery and durable polyethylene terephthalate, over which we put a piece of ordinary plastic pipe.

We place the resulting structure transversely on the edge of a wooden board with the base of the aluminum brand resting on the end of the board and fasten it to the board with half-clamps over a piece of plastic pipe.

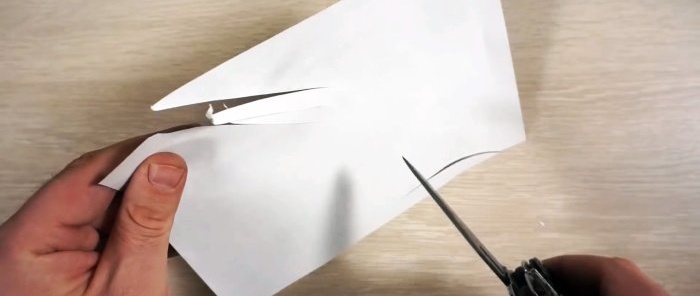

We glue strips of coarse and fine grit sandpaper onto the plastic backing. Also, on the plastic tube inserted into the latch clip, we put pieces of polyethylene terephthalate tube in two places, which we wrap around with clips without latch.

Between the clips without latches we place and clamp a backing with sandpaper, which can be moved back and forth, as well as left and right.

Between the plates we clamp the blunt blade of the knife in the transverse direction, set the sharpening angle by lowering or raising the movable clip-latch along the stand, and begin sharpening one side of the blade.

Then we pull the knot away from the board and rotate it 180 degrees, return it to its place and continue sharpening.

If necessary, replace the coarse-grained sandpaper with fine-grained sandpaper and fine-tune the blade. After which the knife blade acquires razor sharpness.

Watch the video

Similar master classes