How to restore threads in a housing using a screwdriver

Often, in case parts made of aluminum alloys, due to inaccurate alignment of the parts being connected or simply a lack of skill, threaded holes are damaged when screwing in fastening bolts or studs.

Damaged threads are usually restored using a repair insert called a sleeve, made of durable stainless steel. It is screwed in using a special tool designed for this purpose. In order not to spend money on purchasing a repair kit, you can do the insert yourself, and this can be done by any adult who has at least basic skills in handling simple metal tools.

How to repair a threaded hole in a housing

It is impossible to screw a mounting bolt or stud into a damaged threaded hole. To do this, it is necessary to restore the thread in the hole of the body part. We begin repairing a damaged threaded hole by drilling it out with a drill of the appropriate diameter.

The next operation consists of carefully cutting threads in the drilled hole using a tap and a driver manually or mechanically using a drill or screwdriver.

Next, on one side of the steel rod, the diameter of which coincides with the diameter of the cut threaded hole, we also cut a thread using a die and a driver. We insert a steel rod with a thread cut at one end into the chuck of a lathe and drill a longitudinal hole in it in the center for the entire length of the thread after carefully centering the drill relative to the axis of the rod.

Having lubricated the end of the cut thread on the steel rod with grease, tightly screw it into the restored threaded hole in the body part until it stops using a wrench to ensure a strong fixation.

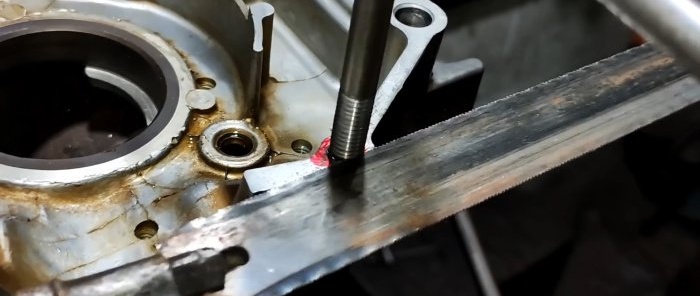

Flush with the surface of the body part, using a hacksaw for metal, we cut off the rod with part of the thread cut on it.

At the entrance to the insert hole, we make a circular chamfer on a drilling machine using a countersink drill.

Now, having lubricated the tap with oil, we very carefully and extremely carefully cut the thread in the steel insert, which we essentially pressed into the aluminum alloy body part.

To ensure the quality of the resulting thread, screw a standard bolt into the newly created threaded hole and make sure that it is completely identical to the thread of the standard mounting bolt.

Watch the video

Similar master classes