Copper wire ring

Today you will learn how to create jewelry using a rather unusual technique. This technique is called wire wrap art (among craftsmen there is a simple name for it - wirework) and involves the creation of all sorts of gizmos by twisting wire.

It must be said that wirework has been living among people for quite a long time - many jewelry are created using this technique. They especially loved twisting jewelry masterpieces out of wire in the Middle Ages - it was believed that the thinner the wire a craftsman could work with, the more skillful he was. This means that the work of such a master was valued more highly.

Currently, the wire twisting technique has entered the subsection of the main popular types of handicrafts, or what we are used to knowing as “hand-made”. The main materials that will be popular here are copper, wire made from special silver alloys, steel, aluminum and semi-jewelry wire made from a copper core coated with a layer of silver. The main tools here are wire cutters, scissors, metal cutting pliers, round nose pliers, duckbill pliers (a special type of round nose pliers with tips beveled at 180 degrees).As well as jewelry tools: crossbars, rollers, jewelry hammers, etc.

It must be said that this technique is not at all as simple as it may seem at first. Wirework requires its adept (let's call him that) to have strong hands, clear movements and a sharp eye. It may take about six months for a beginner’s hands to remember all the necessary movements and turn things more or less smoothly.

Initially, it is recommended to try to start working with aluminum and steel wires. Due to their low cost, you won’t mind spending them on your first endeavors and not be afraid of making a mistake and ruining the wire. Unfortunately, they are not very suitable for more professional projects: aluminum wires are soft and something made from them may not support its own weight, while steel, on the contrary, is too hard and your hands can quickly get tired of it.

The best option is all kinds of copper wire. You can get it both in radio electronics and wires, and in handicraft stores. Copper is docile and soft in the hands, but at the same time strong and durable - it will give life to durable products. The only “but” is that you need to be able to process copper. Therefore, in parallel with studying torsion techniques, you need to get acquainted with the patination of a copper product and its subsequent varnishing. This lesson will look at creating a ring using copper wires... So, let's get started.

To create a copper ring we will need:

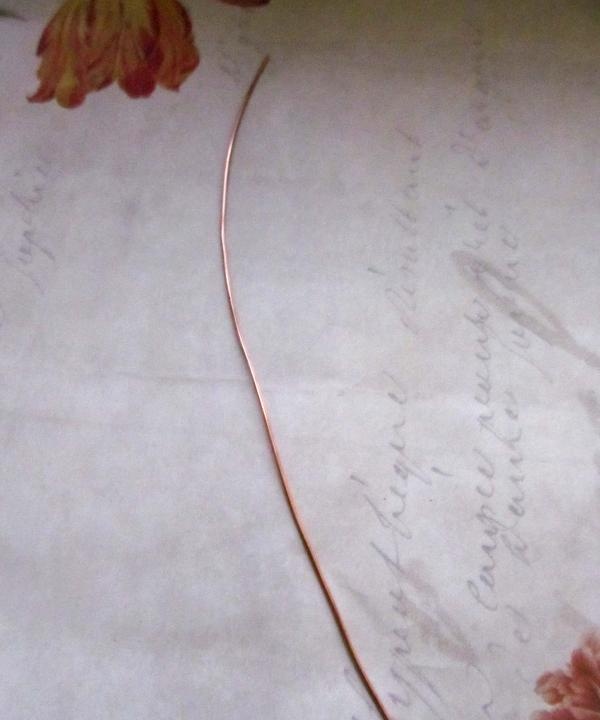

Copper wire in two sizes: 1.0 for the frame, 0.03 for the winding.

Round nose pliers and wire cutters.

Crossbar for winding the base of the ring (we use a regular felt-tip pen).

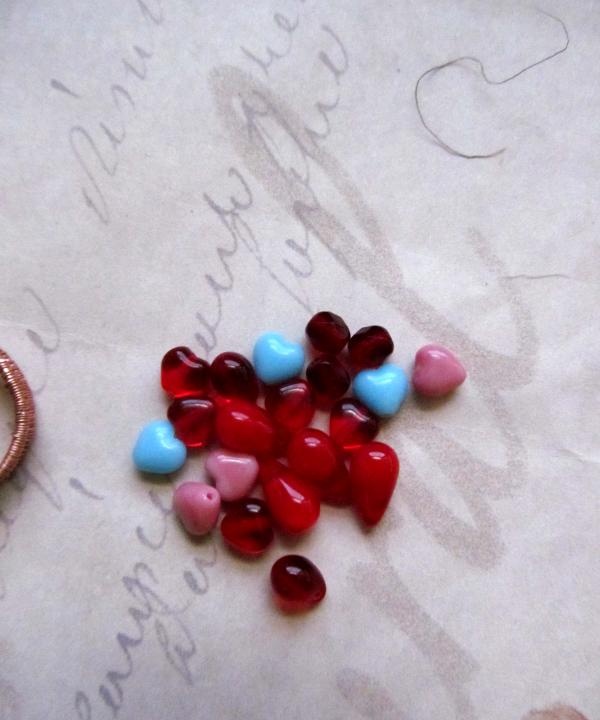

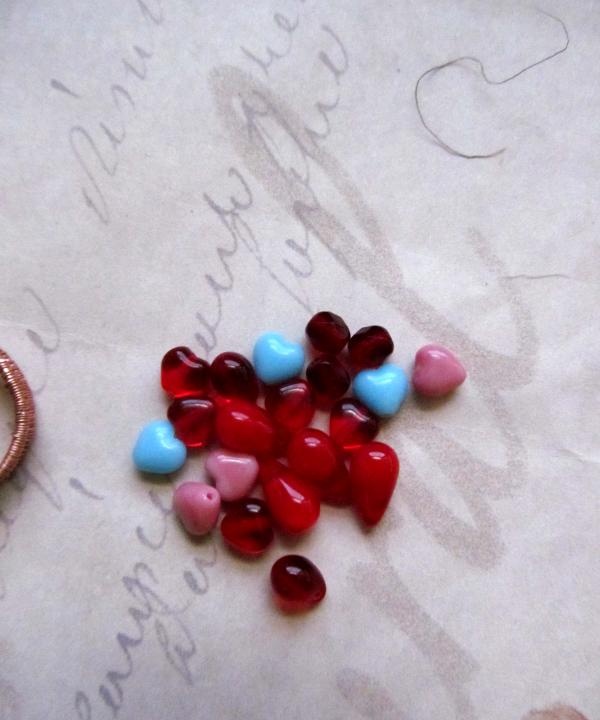

Beads for the core of the ring.

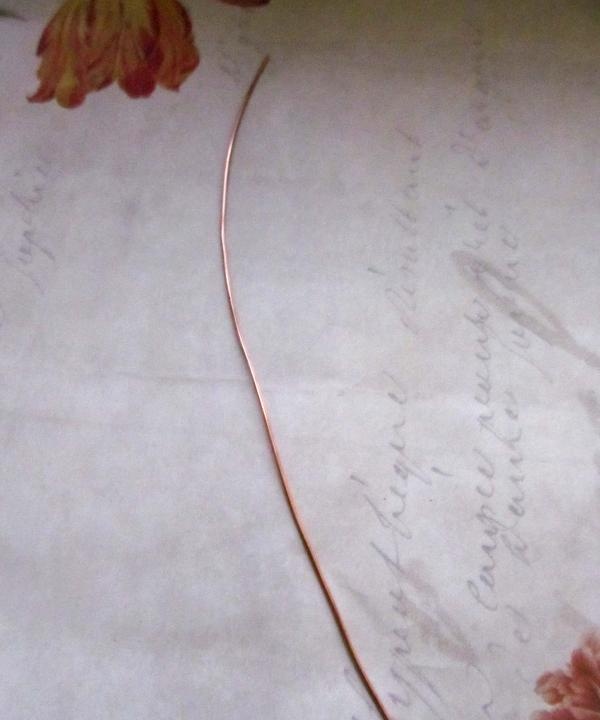

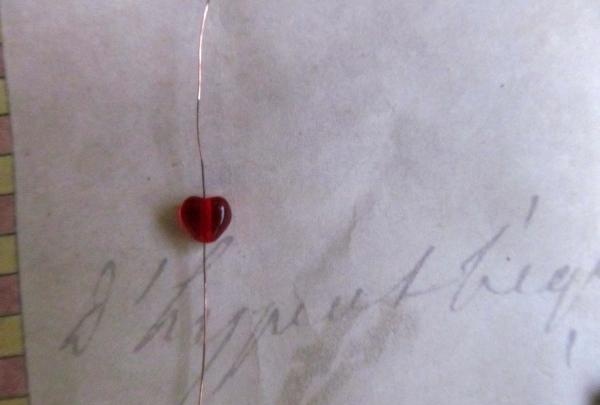

First we take the wire.

We will use three types. The thicker one is the base of the ring.We will braid the base with a thin one and attach the bead.

And the third one, which has droplets at the ends, we will decorate the finished ring with. The droplets on the rings were made using a gas torch. This requires a certain skill, so it is not recommended for beginners - you can get burned and get scalded.

Cut a piece from a piece with thick wire

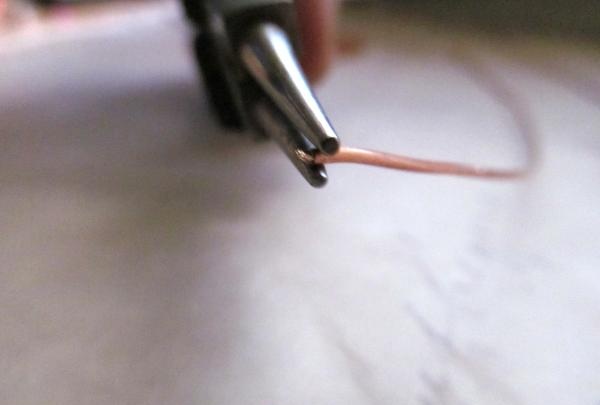

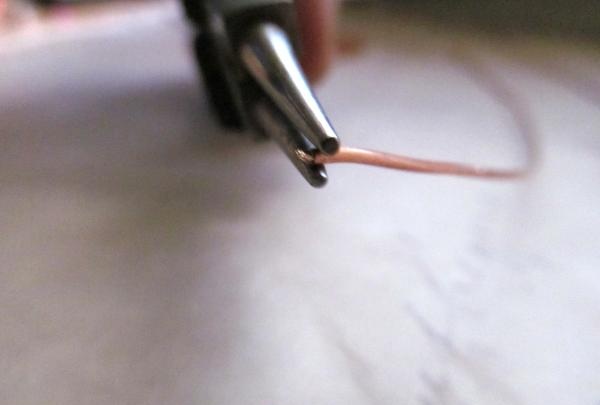

Take our round nose pliers

We clamp the end of the wire between the jaws of the tool

And turning the tool away from you, we form a loop at the end

We form loops on both ends of the wire so that the ends of the ring do not scratch your fingers

Then we take our improvised crossbar and, pressing the wire with our finger, we wrap the wire around the felt-tip pen by its lower end. We need to make two full turns.

As a result we should get the following:

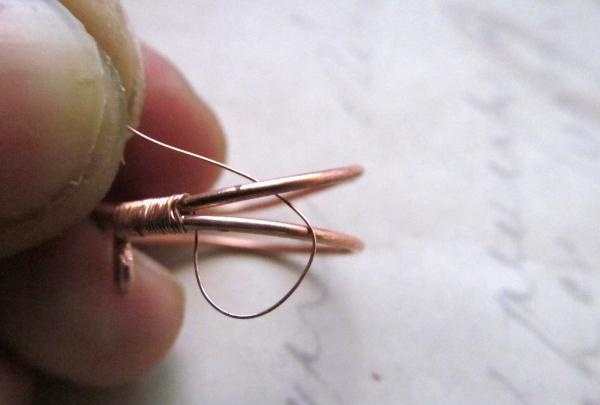

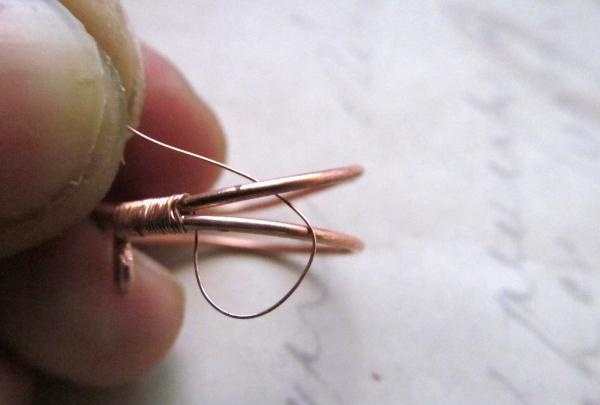

Then, remove the workpiece from the crossbar, take a thin wire and make about 5-6 turns at the base of the loops at the end.

Then we take the end of the leading (the one with which we wrap the base) wire and dive under the top wire of the base.

Tighten the loop.

Then we wrap the top “crossbar” of the base with the leading wire and make a dive in the opposite direction (under the lower “crossbar”). Also then tighten the loop.

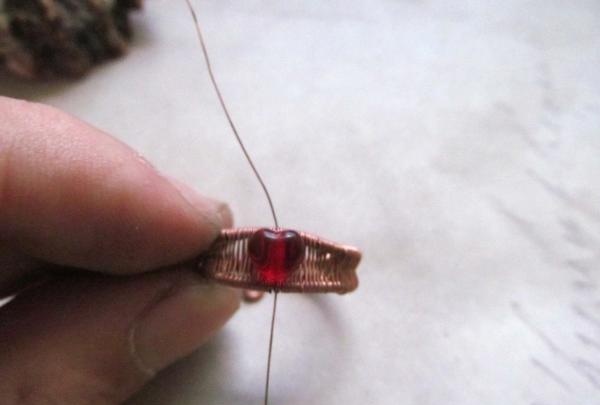

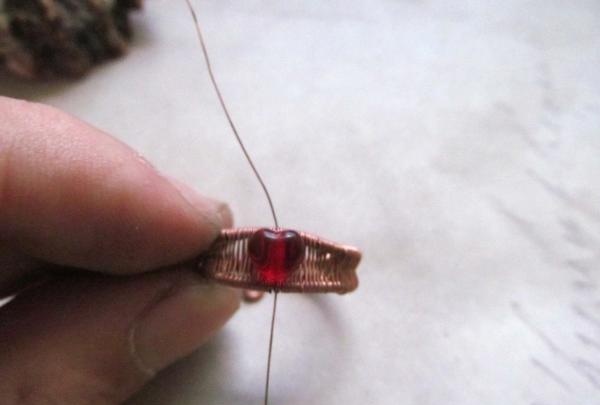

And with such “dives” we braid the entire base of the ring. It is important to do the entire winding under tension, then the braid pattern will lie evenly.

Here is the result, as they say, “halfway”.

In the end you will get this base.

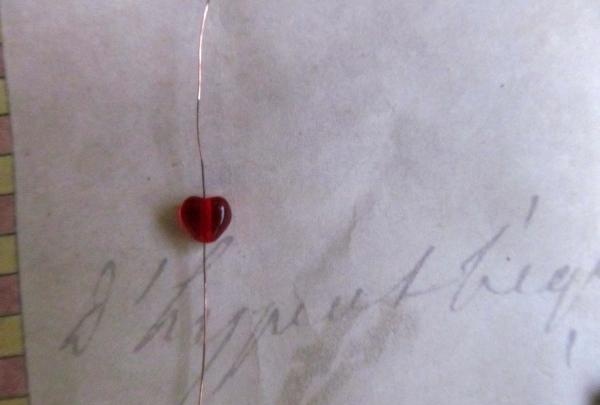

Then we take our beads and string one of them onto a new piece of thin wire.

We find the middle of the ring and insert two ends of the wire with a bead between the turns of the braid. By pulling the wire, we fix the bead, winding both ends to the upper and lower crossbars, and then we pass them several times through the bead and wind it. Then we cut off the excess ends.

Then we take the wire with droplets and wrap it around the bead.

Then we wrap the two ends around the base of the ring and bring them out. We bend it beautifully.

This is how it turns out.

Then the ring is placed in ammonia vapor (regular ammonia) and polished. Here is the result.

It must be said that wirework has been living among people for quite a long time - many jewelry are created using this technique. They especially loved twisting jewelry masterpieces out of wire in the Middle Ages - it was believed that the thinner the wire a craftsman could work with, the more skillful he was. This means that the work of such a master was valued more highly.

Currently, the wire twisting technique has entered the subsection of the main popular types of handicrafts, or what we are used to knowing as “hand-made”. The main materials that will be popular here are copper, wire made from special silver alloys, steel, aluminum and semi-jewelry wire made from a copper core coated with a layer of silver. The main tools here are wire cutters, scissors, metal cutting pliers, round nose pliers, duckbill pliers (a special type of round nose pliers with tips beveled at 180 degrees).As well as jewelry tools: crossbars, rollers, jewelry hammers, etc.

It must be said that this technique is not at all as simple as it may seem at first. Wirework requires its adept (let's call him that) to have strong hands, clear movements and a sharp eye. It may take about six months for a beginner’s hands to remember all the necessary movements and turn things more or less smoothly.

Initially, it is recommended to try to start working with aluminum and steel wires. Due to their low cost, you won’t mind spending them on your first endeavors and not be afraid of making a mistake and ruining the wire. Unfortunately, they are not very suitable for more professional projects: aluminum wires are soft and something made from them may not support its own weight, while steel, on the contrary, is too hard and your hands can quickly get tired of it.

The best option is all kinds of copper wire. You can get it both in radio electronics and wires, and in handicraft stores. Copper is docile and soft in the hands, but at the same time strong and durable - it will give life to durable products. The only “but” is that you need to be able to process copper. Therefore, in parallel with studying torsion techniques, you need to get acquainted with the patination of a copper product and its subsequent varnishing. This lesson will look at creating a ring using copper wires... So, let's get started.

To create a copper ring we will need:

Copper wire in two sizes: 1.0 for the frame, 0.03 for the winding.

Round nose pliers and wire cutters.

Crossbar for winding the base of the ring (we use a regular felt-tip pen).

Beads for the core of the ring.

First we take the wire.

We will use three types. The thicker one is the base of the ring.We will braid the base with a thin one and attach the bead.

And the third one, which has droplets at the ends, we will decorate the finished ring with. The droplets on the rings were made using a gas torch. This requires a certain skill, so it is not recommended for beginners - you can get burned and get scalded.

Cut a piece from a piece with thick wire

Take our round nose pliers

We clamp the end of the wire between the jaws of the tool

And turning the tool away from you, we form a loop at the end

We form loops on both ends of the wire so that the ends of the ring do not scratch your fingers

Then we take our improvised crossbar and, pressing the wire with our finger, we wrap the wire around the felt-tip pen by its lower end. We need to make two full turns.

As a result we should get the following:

Then, remove the workpiece from the crossbar, take a thin wire and make about 5-6 turns at the base of the loops at the end.

Then we take the end of the leading (the one with which we wrap the base) wire and dive under the top wire of the base.

Tighten the loop.

Then we wrap the top “crossbar” of the base with the leading wire and make a dive in the opposite direction (under the lower “crossbar”). Also then tighten the loop.

And with such “dives” we braid the entire base of the ring. It is important to do the entire winding under tension, then the braid pattern will lie evenly.

Here is the result, as they say, “halfway”.

In the end you will get this base.

Then we take our beads and string one of them onto a new piece of thin wire.

We find the middle of the ring and insert two ends of the wire with a bead between the turns of the braid. By pulling the wire, we fix the bead, winding both ends to the upper and lower crossbars, and then we pass them several times through the bead and wind it. Then we cut off the excess ends.

Then we take the wire with droplets and wrap it around the bead.

Then we wrap the two ends around the base of the ring and bring them out. We bend it beautifully.

This is how it turns out.

Then the ring is placed in ammonia vapor (regular ammonia) and polished. Here is the result.

Similar master classes

Particularly interesting

Comments (0)