Laboratory power supply

Good day to all! Today I would like to present to your attention the Laboratory Power Supply (LBP). I think every novice radio amateur is faced with the problem of obtaining the necessary voltage for one or another of his homemade products, because each device requires a different voltage. I also encountered the same problem the other day. It was necessary to power a homemade amplifier, but the necessary voltage was not at hand. Well, this is not the first homemade product I've had problems with. So I got to work.

So, we need:

-Case (you can buy a ready-made one, or you can take it from a computer power supply like I did)

-Transformer with output voltages up to 30V and current up to 1.5 amperes (I took a more powerful trans as 1.5A is not enough for me)

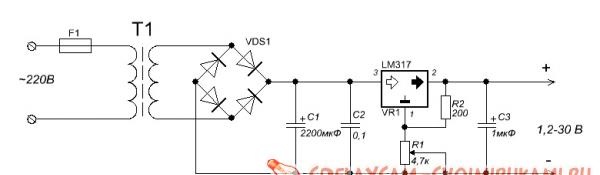

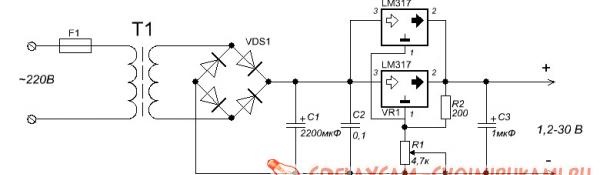

-Simple set of radio components:

-Diode bridge 3A.

-Electrolytic capacitor 50V 2200uF.

-Ceramic capacitor of 0.1 microfarads (to smooth out ripples more).

-LM317 microcircuit (in my case there are 2 such microcircuits).

-Variable resistor at 4.7 kOhm.

-Resistor at 200 ohm 0.5W.

-Ceramic capacitor 1 µF.

-Old analog tester (I used it as a voltmeter).

- Textolite and ferric chlorine (for etching the board).

-Terminals.

-Wires.

-Soldering accessories.

Begin! I took the case from a computer power supply. We disassemble it and take out the insides and saw off the front panel (the one from which the wires come out) as in the photo.

Next, we assemble it back and cut out the front panel of the future power supply from fiberboard; it might be more beautiful from plastic.

We cut off the board fasteners on one side and bend them in such a way that we can then attach the front panel we made to them.

We select a place for the transformer, drill holes in the lower part of the housing and secure the transformer.

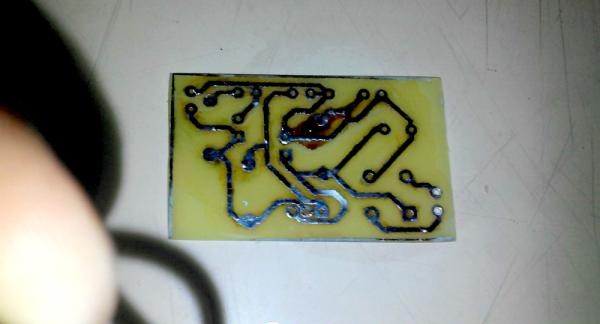

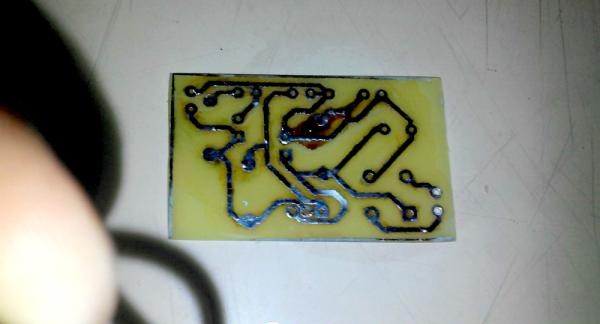

Now let's start assembling the board, first we need to etch it. We transfer the pre-printed board to the PCB.

And throw it into chlorine for 10-20 minutes. After etching, we drill holes and tin the board.

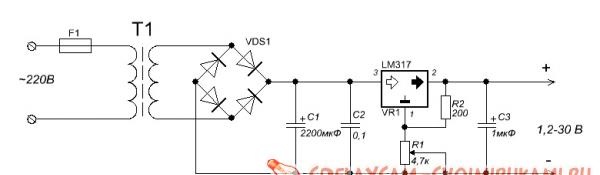

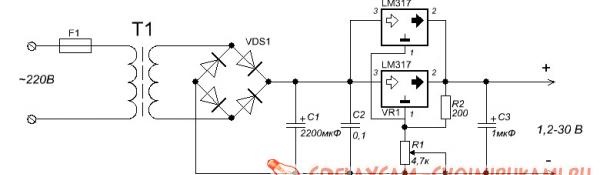

We solder the elements according to the diagram.

We take the wires, assemble the circuit and pack everything into the case. IMPORTANT! (the microcircuit must be installed on a radiator, since under heavy loads it gets very hot and can fail). This is what happened.

Now you need to get a voltmeter from the old tester. To do this, simply cut off the indicator itself from the plastic case.

Next, you need to place a jumper on the tester board in the 50V range, cut a hole in the front panel for our voltmeter and connect the wires. We isolate our board and close the case. I installed a cooler on top to blow air over the radiator on which the microcircuit is installed.

That's all! The laboratory power supply is ready! Good luck to all!

So, we need:

-Case (you can buy a ready-made one, or you can take it from a computer power supply like I did)

-Transformer with output voltages up to 30V and current up to 1.5 amperes (I took a more powerful trans as 1.5A is not enough for me)

-Simple set of radio components:

-Diode bridge 3A.

-Electrolytic capacitor 50V 2200uF.

-Ceramic capacitor of 0.1 microfarads (to smooth out ripples more).

-LM317 microcircuit (in my case there are 2 such microcircuits).

-Variable resistor at 4.7 kOhm.

-Resistor at 200 ohm 0.5W.

-Ceramic capacitor 1 µF.

-Old analog tester (I used it as a voltmeter).

- Textolite and ferric chlorine (for etching the board).

-Terminals.

-Wires.

-Soldering accessories.

Begin! I took the case from a computer power supply. We disassemble it and take out the insides and saw off the front panel (the one from which the wires come out) as in the photo.

Next, we assemble it back and cut out the front panel of the future power supply from fiberboard; it might be more beautiful from plastic.

We cut off the board fasteners on one side and bend them in such a way that we can then attach the front panel we made to them.

We select a place for the transformer, drill holes in the lower part of the housing and secure the transformer.

Now let's start assembling the board, first we need to etch it. We transfer the pre-printed board to the PCB.

And throw it into chlorine for 10-20 minutes. After etching, we drill holes and tin the board.

We solder the elements according to the diagram.

We take the wires, assemble the circuit and pack everything into the case. IMPORTANT! (the microcircuit must be installed on a radiator, since under heavy loads it gets very hot and can fail). This is what happened.

Now you need to get a voltmeter from the old tester. To do this, simply cut off the indicator itself from the plastic case.

Next, you need to place a jumper on the tester board in the 50V range, cut a hole in the front panel for our voltmeter and connect the wires. We isolate our board and close the case. I installed a cooler on top to blow air over the radiator on which the microcircuit is installed.

That's all! The laboratory power supply is ready! Good luck to all!

Similar master classes

Particularly interesting

Comments (11)