The most reliable connection of wires without a soldering iron

If you need to make a critical connection of wires, but you don’t have a soldering iron at hand, or there is no way to power it, then this little trick will come in handy. After all, chance doesn’t choose when to take you by surprise and you need to be prepared for anything. An ordinary gas lighter will be used as a soldering iron, so the twist will still be soldered and the strength of the wire will be exactly the same as that of a solid piece.

Will need

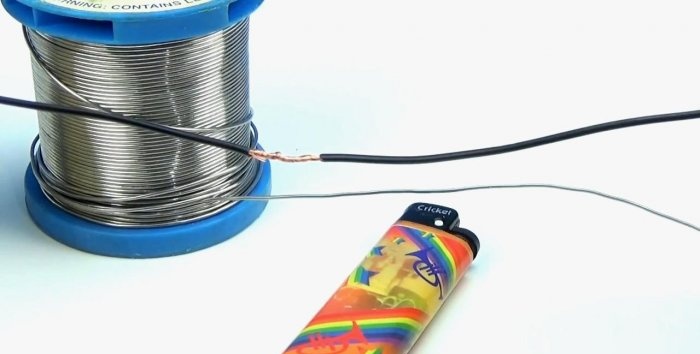

- Gas lighter.

- Heat-shrink tubing. You can buy it in a store, but I ordered it in China - heat shrink tubing set

- Tubular solder with rosin. If you're not familiar, it's a thin tube of solder wound on a spool. And in the center of the tube there is a strip with rosin or active flux, I ordered - HERE.

We connect the wires securely without a soldering iron

We take a piece of heat-shrinkable tubing approximately 50 mm long and put it on one of the two wires.

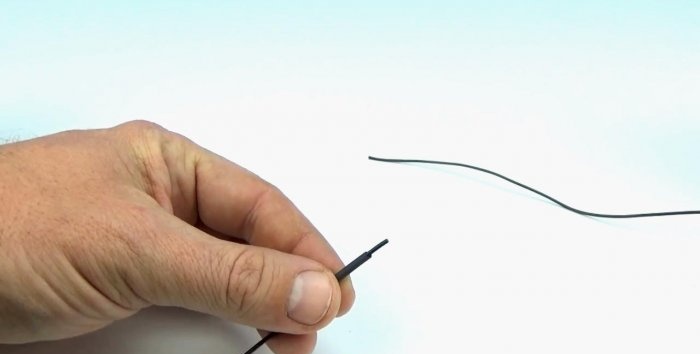

Then, using a stripper, wire cutters or knife, we strip 30 mm of insulation from each wire.

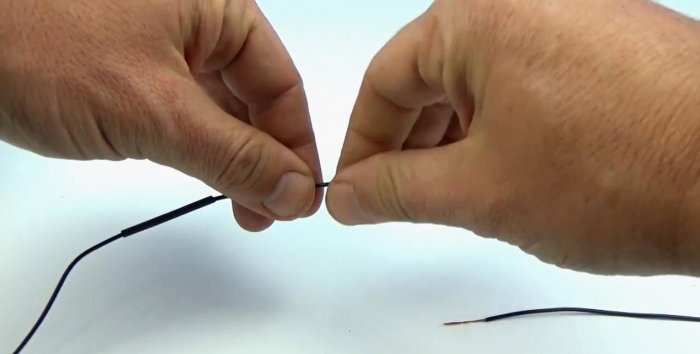

We twist the frayed veins together.

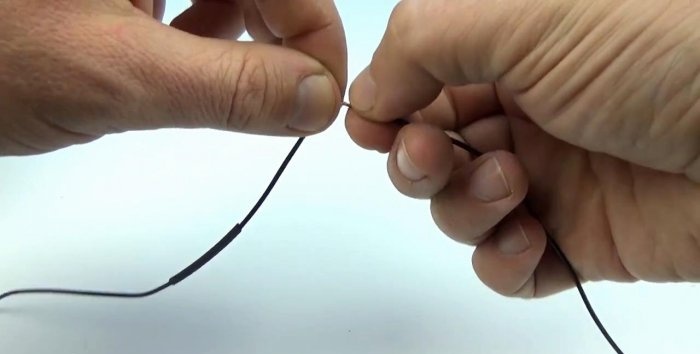

Now we wind the exposed wires onto each other.We make a cross and wind half of the core onto the right one, and the right one onto the left.

It should look like this.

Soldering without a soldering iron

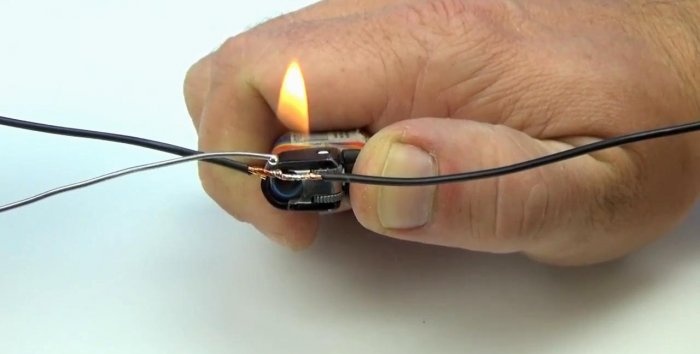

We take solder and heat the twist with a lighter. Just don’t bring it directly into an open flame, but barely touch it - there’s no need for excessive temperature.

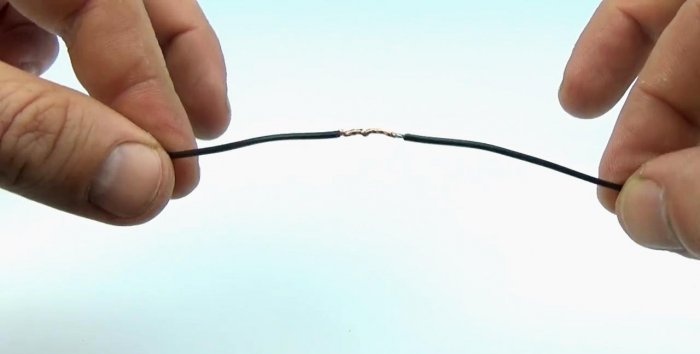

We touch the solder to the twist and since it is hot enough, the solder melts and spreads over it perfectly.

As a result, the connection will be no worse than one soldered with a soldering iron.

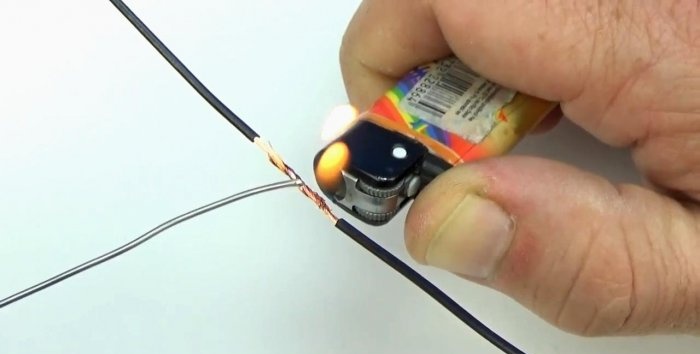

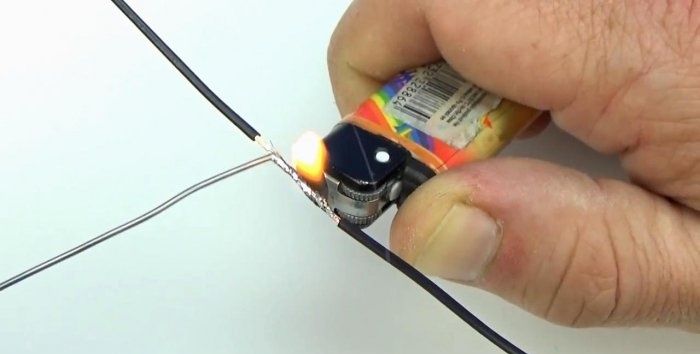

I will repeat from a different angle. Heat it with a lighter and apply solder.

It flows well over copper conductors.

The result is excellent.

We move the heat shrink that was put on earlier to the middle of the soldered twist.

And warm it up with the flame of a lighter.

As a result, you have a very reliable, strong connection between two wires.

This method will help you out when you don’t have a soldering iron at hand.

- Tip #1: If the wire is not fresh, then it must first be lubricated with solder paste or liquid flux.

- Tip #2: If the wire is thick, then tubular solder with flux can be wound in a chaotic manner directly on top of the twist. Then heat it with a lighter and everything will spread by itself.

I personally am very pleased with the quality of Chinese solder. Compared to our POS 61, this is heaven and earth. But, as you know, there are no comrades for taste and taste. Good luck everyone!

Watch the video

Similar master classes

How to perfectly solder a wire without a soldering iron

How to make tubes for quick soldering of wires from ordinary

The strongest connection of large cross-section wires without thickening

How to reliably connect wires without soldering

Solder sleeves - your salvation when there is no way

An innovative way to connect two wires

Particularly interesting

Comments (1)