Generator for wind turbine

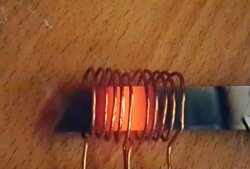

Let's start assembling the mechanical part of the generator. The generator parts are shown below. All of them are made of steel. A transformer steel strip is used for the ring, but a steel sleeve can also be used.

Let's pass the wire from the coil into the hole in the base.

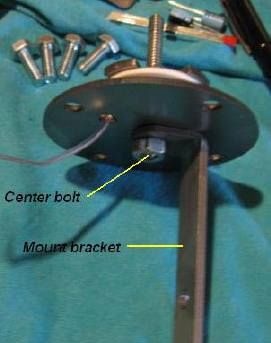

Having secured the nut on the axis, we will tighten the package from the corner, the round base board, the coil and the cross-shaped magnetic circuit with another nut. See pictures below.

Let's install a steel magnetic core in the form of a ring on top of the coil and insert 4 bolts. Bolts with a diameter of 6mm and a length of 20mm.

Install the top plate, tightening it with bolts. Tighten the bolts lightly to avoid damaging the threads on the plate.

By tightening the central nut, we press the cross-shaped magnetic circuit to the coil so that it does not protrude beyond the plane of the top plate.

At this point, the stator assembly can be considered complete.

Let's start assembling the rotor. We need 8 pieces of permanent magnets and bearings.

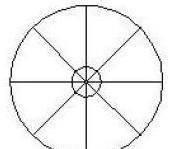

Next, you need to mark the places for attaching the magnets. To do this, draw a template-drawing

And placing it on the rotor...

Use a marker to mark the places where the magnets are attached.

The magnets on the rotor should whatedit according to pole position. Therefore, before sticking them on, you need to mark the poles of the same name, for example, with a marker. The easiest way to do this is to collect all the magnets in a column. In this case, all poles of the same name will be oriented in one direction.

Place the magnets on the rotor, alternating poles.

After installing the magnets, you can apply glue around them for final fixation. However, the magnets hold up well even without glue.

Place the rotor on the axle and secure it.

Actually, we're done with the mechanics. Now, by rotating the rotor by hand, you can get 3..4V AC output voltage. After the rectifier you get 7...9V.

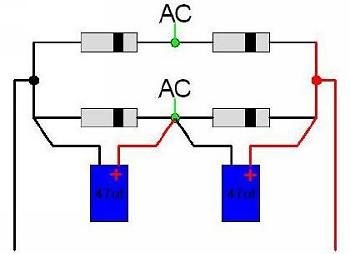

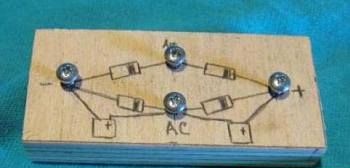

Let's assemble a rectifier and a doubling voltage multiplier. Its diagram is shown in the figure below. As diodes, you can take any diode with a current of 1 A or higher and a voltage of at least 50V. Electrolytic capacitors 47.0uF x 50V, or any larger capacity.

If multiplication is not needed, then we connect the capacitor between the plus and minus of the output and remove them from the diodes.

In the absence of a soldering iron, the rectifier can be assembled as shown in the pictures below.

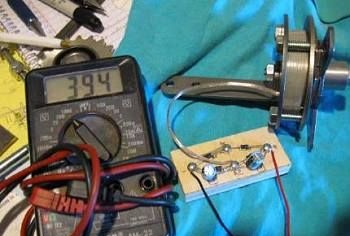

Let's connect the generator to the rectifier at the AC points.

And connect to the output multimeter.

With fast rotation, the output can reach almost 40 V without load.

In the future, this generator can be connected to various turbines.

For example, with vertical axis.

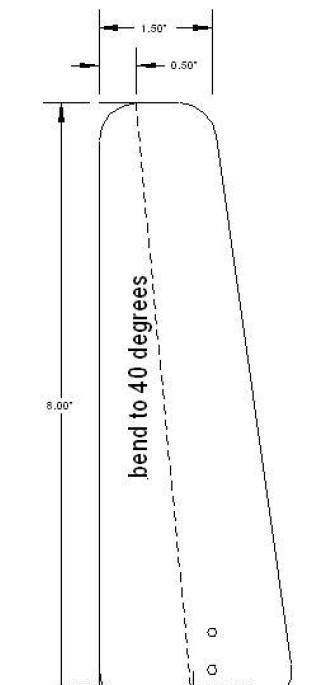

Or, having made blades from thin aluminum, assemble a turntable with a horizontal axis of rotation.

A drawing of the blade is shown in the figure below. All dimensions are given in inches, 1 inch = 25.4 mm.

Actually, that's all. Then you can use this windmill and generator as you please.

Good luck!

Similar master classes

Particularly interesting

Cable antenna for digital TV in 5 minutes

A selection of simple and effective schemes.

Three-phase voltage from single-phase in 5 minutes

Starting a three-phase motor from a single-phase network without a capacitor

Eternal flashlight without batteries

How to make an inexpensive but very powerful LED lamp

Comments (7)