Eternal flashlight without batteries

In our world, quite a lot of people are engaged in homemade experiments in home laboratories and workshops. For some, it is a way to assert themselves, for others, it is a desire to develop their abilities. So what if it’s an experiment made from hastily glued parts. The main thing is that the device or circuit works. Today we will analyze just such an invention, made practically on our knees. However, it is based on unshakable principles and laws of physics that cannot be denied.

We will talk about a flashlight that works without batteries. Perhaps someone has already seen on the Internet the simplest Faraday generator, which allows you to ignite a small Light-emitting diode. Assemblies from an almost dead battery, autotransformer and transistor, which are capable of powering at an initial voltage of tenths of a volt Light-emitting diode on 3V is also no longer uncommon.

Here the author went a little further, modernizing the device circuit, adding a rectifier, a supercapacitor (ionistor), resistance and completely eliminating the power source.As a result, the flashlight's operation has become much more stable and efficient. And if you shake the case for a few minutes, it can be charged for a long time LED. How it works? Let's figure it out.

Principle of operation

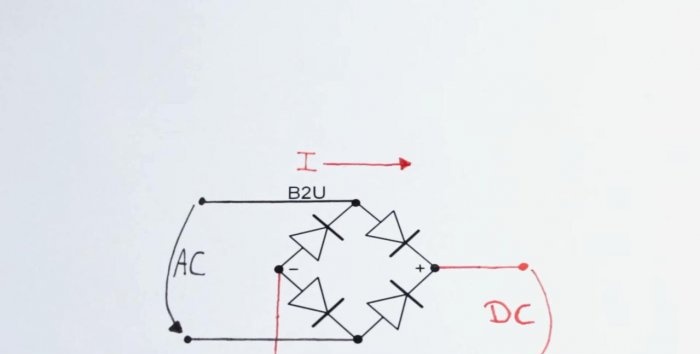

The device consists of several inductors that you can assemble yourself. The primary inductor actually serves as a power source or completely replaces its usual counterpart - the battery. Due to the movement of a rod of permanent magnets in it, an electric current is induced. Due to the oscillatory movements in the magnetic field, electric waves are created emanating from the coil at a certain frequency. A rectifier or diode bridge helps stabilize them and convert them into direct current.

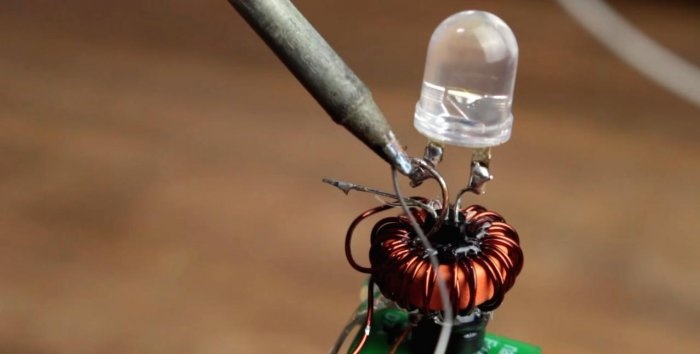

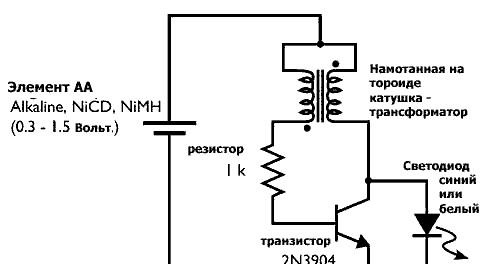

Without a storage capacity, such a device would have to be constantly shaken, so the next element in the circuit is a supercapacitor that can be recharged like a battery. Next, a step-up transformer or voltage converter is connected, which consists of a toroidal ferrite coil and two windings - base and collector. The number of turns can be the same, and is usually 20-50. The transformer has a middle connection point at opposite ends of both windings, and three outputs to the transistor. The autotransformer increases tiny current pulses into sufficient ones for operation LED, and a bipolar transistor is connected to control them. A similar electrical circuit has different names in different sources: joule thief, blocking generator, Faraday generator, etc.

The necessary resource base for homemade products

Materials:

- PVC pipe, diameter 20 mm;

- Copper wire, diameter – 0.5 mm;

- Low-power reverse conduction transistor;

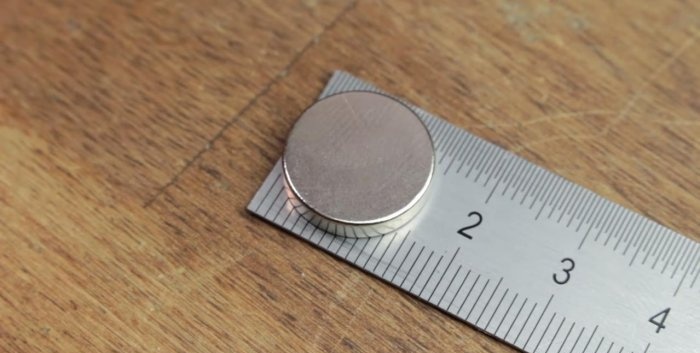

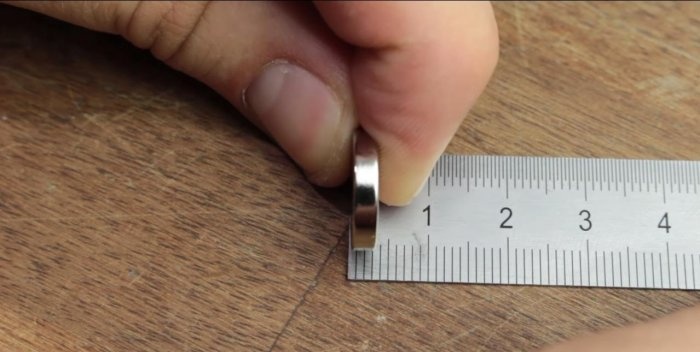

- Neodymium magnets are round, size 15x3 mm;

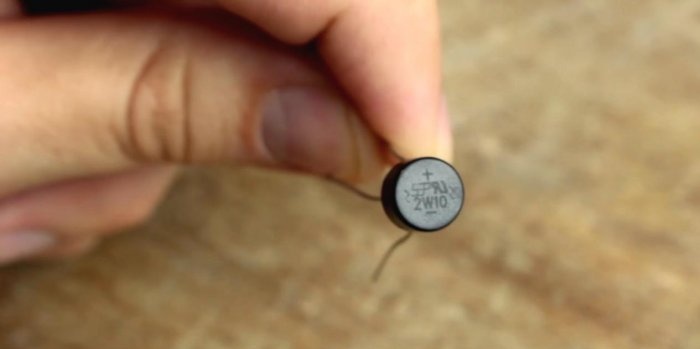

- Diode bridge or rectifier 2W10;

- Resistor;

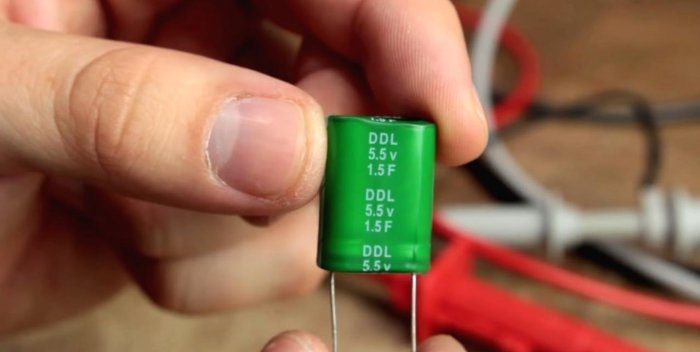

- Supercapacitor or ionistor 1F 5.5V

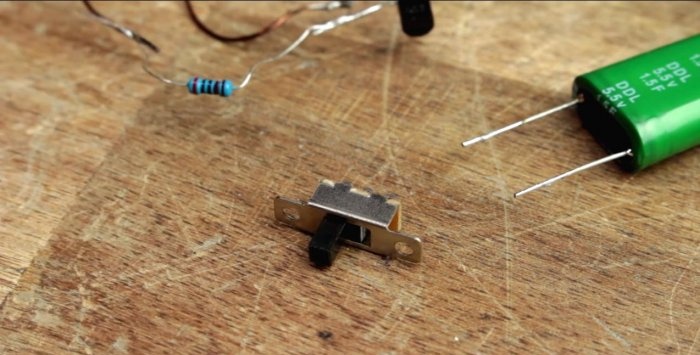

- Switch button;

- Light-emitting diode white or blue at 5V;

- Transparent epoxy resin type adhesive;

- Hot glue;

- Pieces of plywood, cotton wool;

- Copper wiring insulation.

- Soldering iron;

- Hot glue gun;

- Hacksaw for metal;

- File, sandpaper.

Flashlight making process

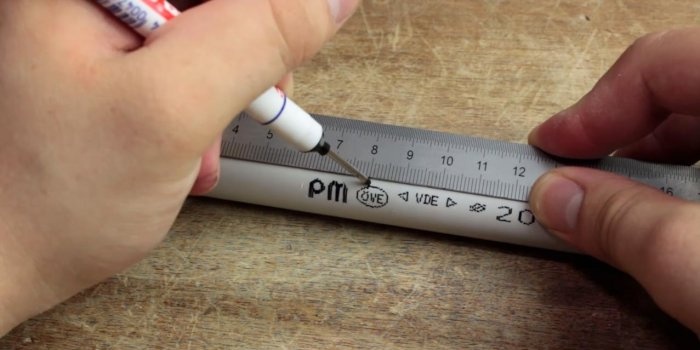

We will make the body of the flashlight from PVC pipes. Mark a segment 16 cm long and cut it with a hacksaw.

From the center of the segment we mark 1.5 cm in each direction. This results in a winding area 3 cm wide.

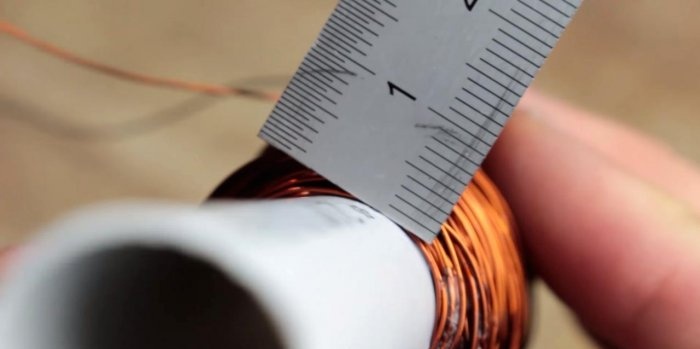

Next, we take a copper wire with a cross-section of 0.5 mm, leave one end about 10-15 cm long, and wind the wire onto the flashlight body tube according to the markings manually. You will have to wind quite a lot, more than half a thousand turns. The first few of them can be fixed with glue. We press the initial row of the coils tightly against each other, and make it strictly consistent.

At its maximum points the winding should be approximately half a centimeter thick. We clean both ends of the wire with sandpaper for reliable soldering.

The movable magnetic core of the coil can be either solid or assembled in parts. Neodymium magnets are selected according to the inner diameter of the PVC tube. The required length of the magnetic rod is experimentally obtained, through the vibrations of which an electric current will be created.

The author used ten 3 mm thick magnets to obtain a length that was as rational as possible for such vibrations, and at the same time equal to the width of the winding.

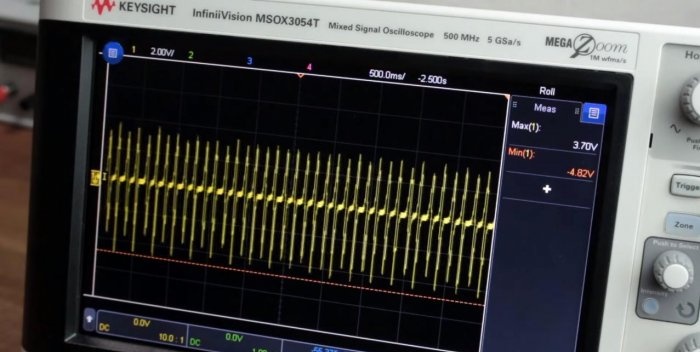

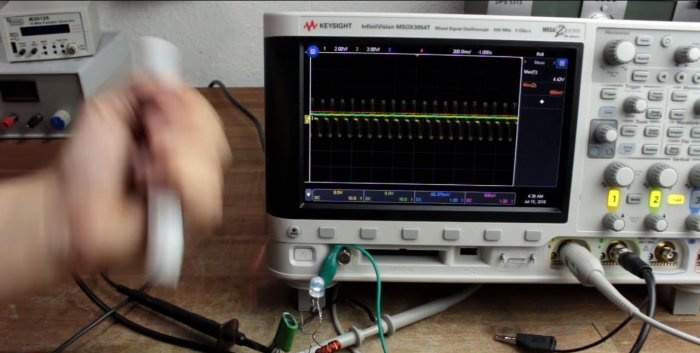

On the oscilloscope scale you can see the difference between the potentials obtained from the vibrations of one and ten magnets. The author received a voltage of 4.5V from the oscillations of the magnetic rod. It also clearly shows the cyclicity of the sinusoid in intervals of varying frequency.

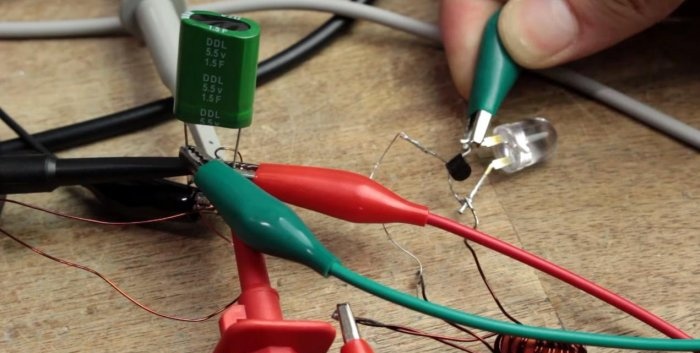

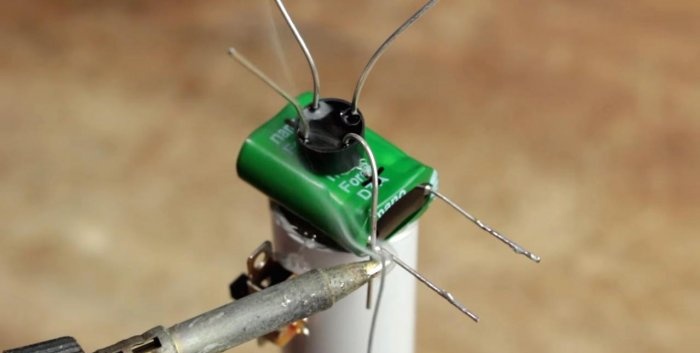

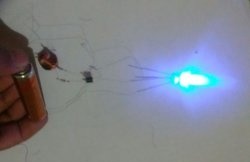

At this stage, following the example of the author, you can connect an LED directly to the output ends of the coil and check its performance. As you can see in the photo, the LED reacts to the movement of the magnetic rod and the pulse current it creates.

Now you need to plug both ends of the tube so as not to hold them with your hands while shaking. To do this, use the same hacksaw to cut out several patches of plywood, process the edges with a file, line them with cotton wool on the back side to soften them, and place them on glue so they don’t fall out.

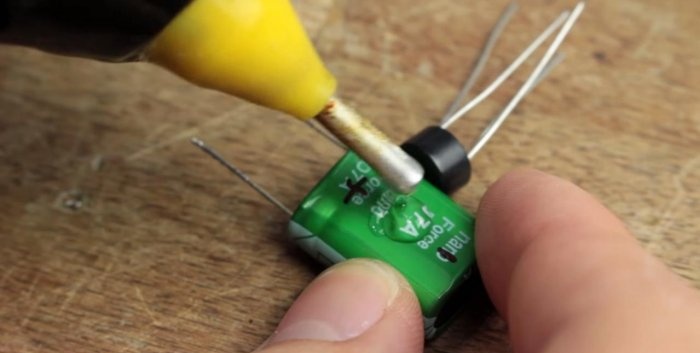

It's time to connect the rectifier. The diagram shown in the photo shows which two of its four contacts are connected to the coil. Such a diode bridge is capable of receiving alternating current and delivering direct current in strictly one direction.

A step-up autotransformer will help convert low spontaneous pulses from the primary coil into sufficient voltage to operate the LED due to the self-induction of one of the windings - the collector. Since it is connected to the base winding, a constant and stable electric current will be supplied to the supercapacitor in sufficient quantity. The resistor will limit the excess of permissible values. A capacitor of sufficient capacity was also selected by the author experimentally using measurements of outgoing signals with an oscilloscope.

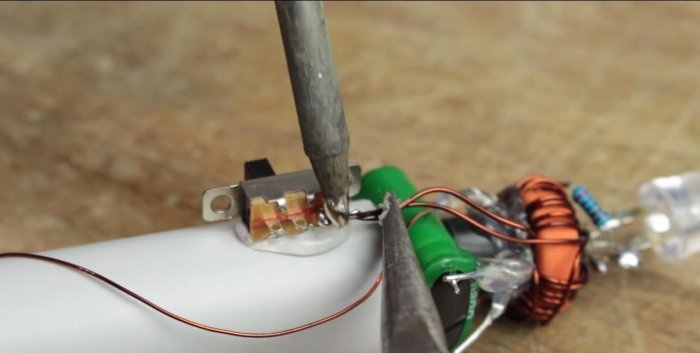

This circuit is closed by a reverse bipolar transistor, which controls the incoming electric current to the LED.You can assemble the circuit without a board, since there are not many parts. We mount the switch button on one of the contacts coming from the autotransformer.

The author chose to assemble his improvised flashlight design using hot glue, while simultaneously improving the insulation of the contact groups. The switch button is located on the side of the flashlight body. The author pasted the main elements of the circuit one on top of the other from one of the ends. The closing element remains the LED, which can be enhanced with protective glass or a reflector.

Despite the unsightly appearance of the device, suitable only for laboratory-experimental home-made products, such a flashlight is quite functional and, on occasion, will not let the darkness disappear. It is easy to assemble such a circuit at home and at minimal cost. And the complete absence of batteries makes it a truly useful device for various emergency situations.