Simple 12V Induction Heater

A simple induction heater consists of a powerful high-frequency generator and a low-resistance coil-circuit, which is the load of the generator.

A self-excited generator generates pulses based on the resonant frequency of the circuit. As a result, a powerful alternating electromagnetic field with a frequency of about 35 kHz appears in the coil.

If a core of conductive material is placed in the center of this coil, electromagnetic induction will occur inside it. As a result of frequent changes, this induction will cause eddy currents in the core, which in turn will lead to the release of heat. This is the classic principle of converting electromagnetic energy into thermal energy.

Induction heaters have been used for a very long time in many areas of production. With their help, you can do hardening, non-contact welding, and most importantly, spot heating, as well as melting of materials.

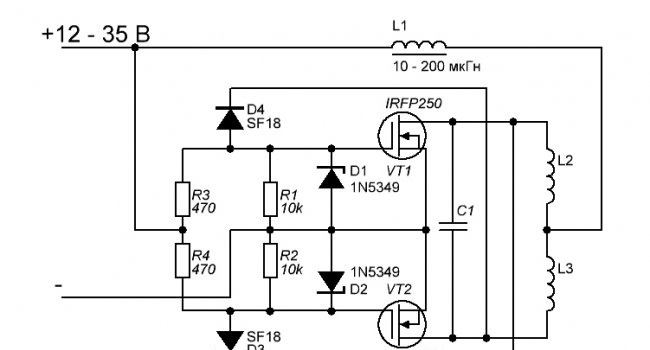

I'll show you the circuit of a simple low-voltage induction heater, which has already become a classic.

We will simplify this circuit even further and will not install zener diodes “D1, D2”.

Items you will need:

1. 10 kOhm resistors – 2 pcs.

2. 470 Ohm resistors – 2 pcs.

3. Schottky diodes 1 A – 2 pcs. (Others are possible, the main thing is for a current of 1 A and high-speed)

4. Field-effect transistors IRF3205 – 2 pcs. (you can take any other powerful ones)

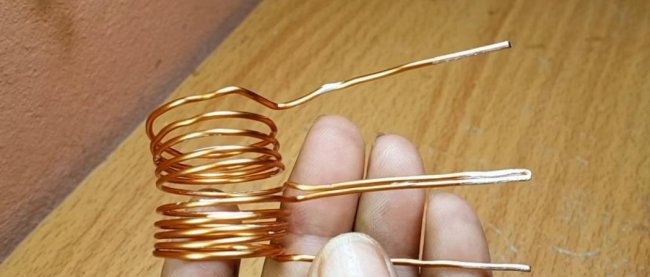

5. Inductor “5+5” - 10 turns with a tap from the middle. The thicker the wire, the better. Wrapped on a wooden round stick, 3-4 centimeters in diameter.

6. Throttle - 25 turns on a ring from an old computer block.

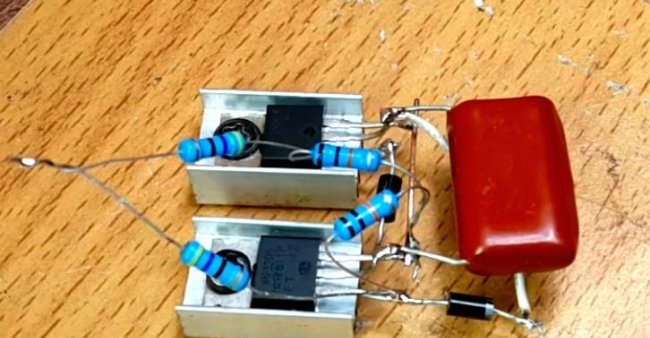

7. Capacitor 0.47 µF. It is better to collect the capacitance with several capacitors and for a voltage of at least 600 Volts. At first I took it to 400, as a result of which it began to heat up, then I replaced it with a composite of two in series, but they don’t do that, I just didn’t have any more at hand.

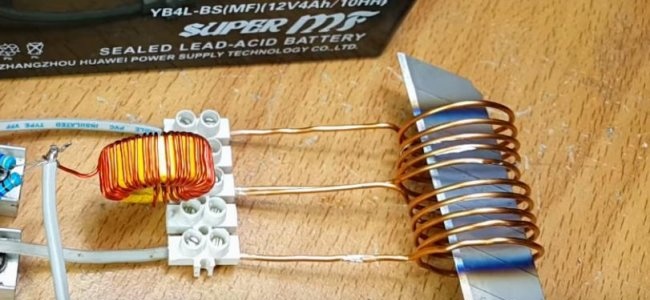

We wind the inductor.

I assembled the entire circuit using a surface-mounted installation, separating the inductor from the entire circuit with a block. It is advisable to place the capacitor in close proximity to the coil terminals. Not like mine in this example in general. I installed transistors on radiators. The entire installation was powered by a 12 Volt battery.

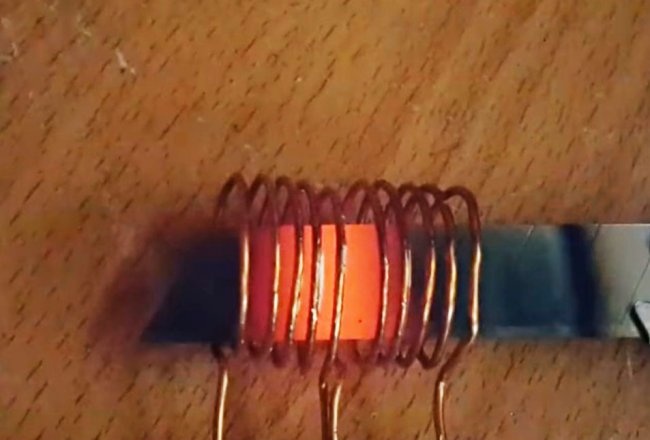

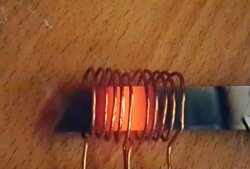

Works great. The blade of a stationery knife heats up to red very quickly. I recommend everyone to repeat it.

After replacing the capacitor they no longer got hot. Transistors and the inductor itself heat up if they work constantly. For a short time - almost not critical.

I also recommend watching:

A self-excited generator generates pulses based on the resonant frequency of the circuit. As a result, a powerful alternating electromagnetic field with a frequency of about 35 kHz appears in the coil.

If a core of conductive material is placed in the center of this coil, electromagnetic induction will occur inside it. As a result of frequent changes, this induction will cause eddy currents in the core, which in turn will lead to the release of heat. This is the classic principle of converting electromagnetic energy into thermal energy.

Induction heaters have been used for a very long time in many areas of production. With their help, you can do hardening, non-contact welding, and most importantly, spot heating, as well as melting of materials.

I'll show you the circuit of a simple low-voltage induction heater, which has already become a classic.

We will simplify this circuit even further and will not install zener diodes “D1, D2”.

Items you will need:

1. 10 kOhm resistors – 2 pcs.

2. 470 Ohm resistors – 2 pcs.

3. Schottky diodes 1 A – 2 pcs. (Others are possible, the main thing is for a current of 1 A and high-speed)

4. Field-effect transistors IRF3205 – 2 pcs. (you can take any other powerful ones)

5. Inductor “5+5” - 10 turns with a tap from the middle. The thicker the wire, the better. Wrapped on a wooden round stick, 3-4 centimeters in diameter.

6. Throttle - 25 turns on a ring from an old computer block.

7. Capacitor 0.47 µF. It is better to collect the capacitance with several capacitors and for a voltage of at least 600 Volts. At first I took it to 400, as a result of which it began to heat up, then I replaced it with a composite of two in series, but they don’t do that, I just didn’t have any more at hand.

Making a simple 12V induction heater

We wind the inductor.

I assembled the entire circuit using a surface-mounted installation, separating the inductor from the entire circuit with a block. It is advisable to place the capacitor in close proximity to the coil terminals. Not like mine in this example in general. I installed transistors on radiators. The entire installation was powered by a 12 Volt battery.

Works great. The blade of a stationery knife heats up to red very quickly. I recommend everyone to repeat it.

After replacing the capacitor they no longer got hot. Transistors and the inductor itself heat up if they work constantly. For a short time - almost not critical.

Watch the assembly and testing video:

I also recommend watching:

Similar master classes

Particularly interesting

Comments (12)