Powerful DIY blower

A very powerful blower that produces a good air flow that can easily blow out any dust from the computer system unit. Such high power is achieved by the optimal design of the installation, the use of a powerful and high-speed engine, and an energy-intensive battery from a screwdriver.

A leaf blower can find a variety of uses at home and in your workshop. I have already shown you one.

Its big plus is its mobility, since everything works without a network and anywhere.

The operating principle of the turbine is centrifugal.

Needed for production

- Plexiglass.

- PVC pipes: one large diameter pipe, which is used for sewerage. And one of small diameter, like for a water pipe.

- Powerful 775 Series 12V DC Motor, which can be purchased at Ali Express.

- Battery from a screwdriver.

- Switch.

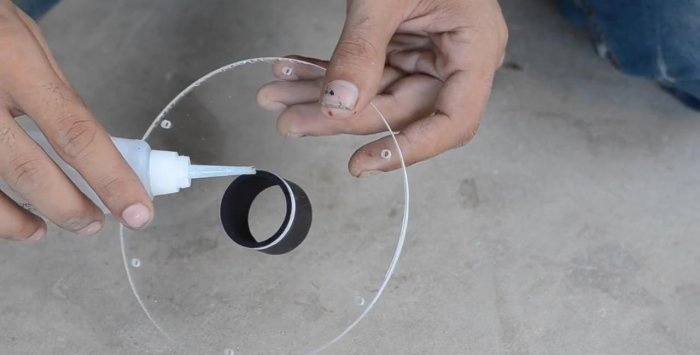

- Secondary glue.

Making a Powerful Blower

Cut the ring from the large pipe.

Place it on a sheet of plexiglass and trace it.

Using a ballerina type drill, cut out two circles from plexiglass. Just not the same diameter, 2 cm larger.

The end result is this kit for assembling the case.

We mark both round pieces and drill holes at distances from the edge of about 0.5 cm.

In one of the round pieces we drill a hole for the engine.

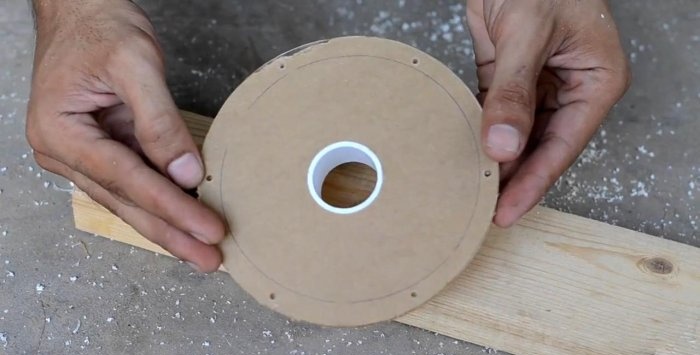

Cut a small piece of pipe. This will be the air intake.

We drill a hole under it in the second round piece.

Let's try it on for now.

Next, take a piece of PVC pipe 15-20 cm long and cut it on one side with a round nozzle to make a tight fit to the housing ring.

Apply it to the ring and circle it.

We make a hole in the ring for the pipe. First we drill with a round nozzle. And then we use a file to give it an oval shape, under the adjacent pipe.

Glue it with superglue. This will be the air outlet.

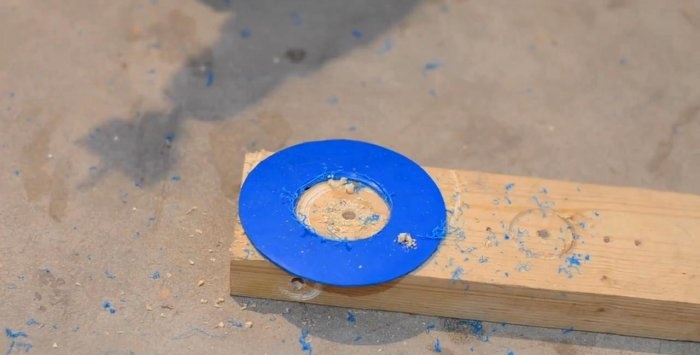

We paint all the parts.

The body is ready. Let's move on to making the impeller.

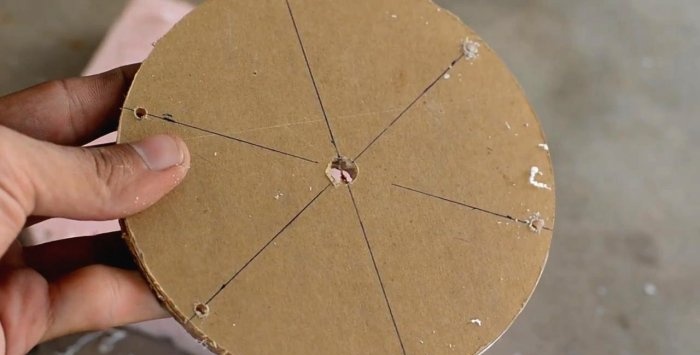

To do this, cut out round pieces of smaller diameters from the canister.

We cut off the tube from the body of the ballpoint pen and glue it into the center of one circle with second-time glue.

In the second circle we make a hole for air intake.

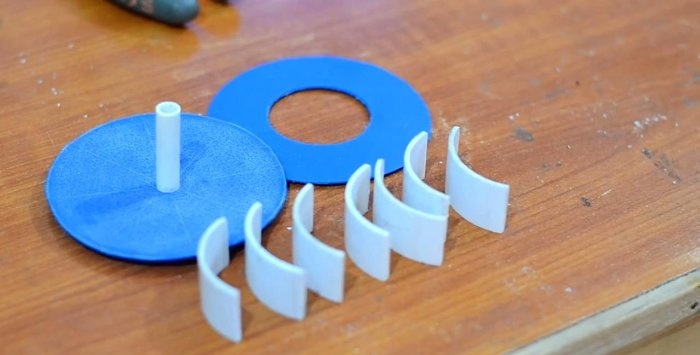

The blades are made from PVC pipe. Cut rings of equal thickness.

Cut into semicircles.

The impeller assembly kit is ready.

But before we begin assembly, we will make a semicircular cut in each blade.

Glue the blades.

Glue the second circle on top.

Now we assemble the entire turbine together. Remove the protective layer from the plexiglass. We glue the air intake tube into one round piece.

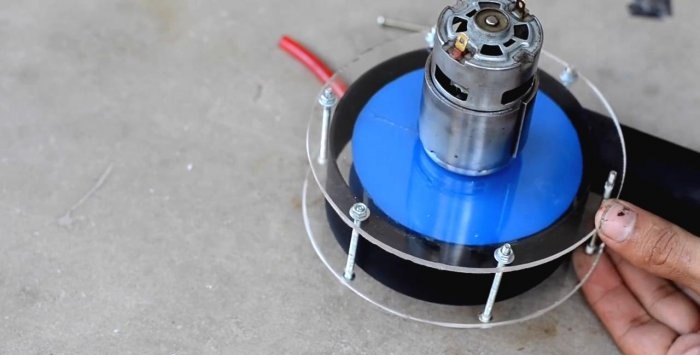

On the other side we fasten the engine.

Eventually:

To put the impeller on the motor shaft, I used a cable braid of a suitable size.

I cut it to the required length and put on the impeller.

Next, we assemble the entire body together.

We fix it with long bolts and nuts.

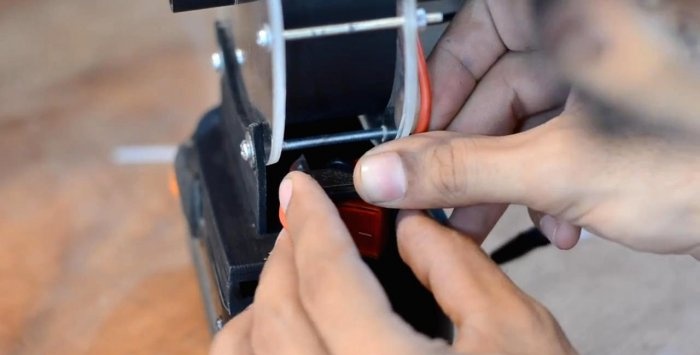

To keep everything on the screwdriver battery, I made a stand like this and some wood.

Painted it.

Solder the wires to the switch and to the motor.

We attach the switch to the stand with glue.

The powerful blower is ready.

Trial

Turn it on. Very powerful pressure. Any dust from the system unit is blown out in no time!

The main merit here, of course, is the high-speed 150 W engine.

Watch the video

Similar master classes

Particularly interesting

Comments (1)