Sandpaper grater

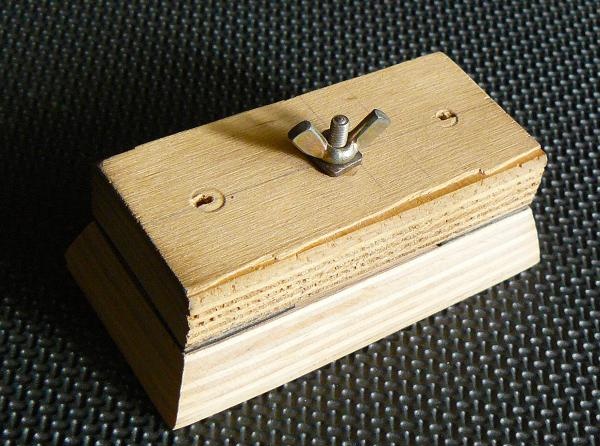

Very often when making crafts it is necessary to use sandpaper to fit or finish the product. For such cases, I suggest making a small grater that will facilitate the sanding process. Its advantages are that it holds sandpaper well, is comfortable in the hand, and the ability to quickly replace sandpaper.

You'll need:

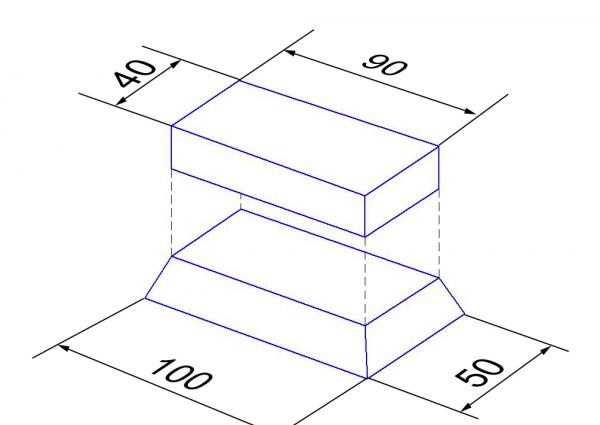

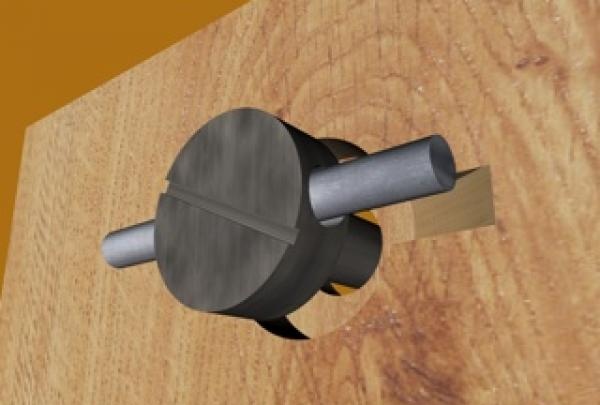

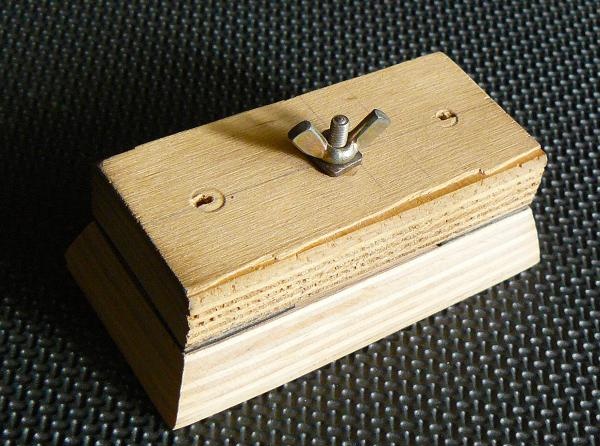

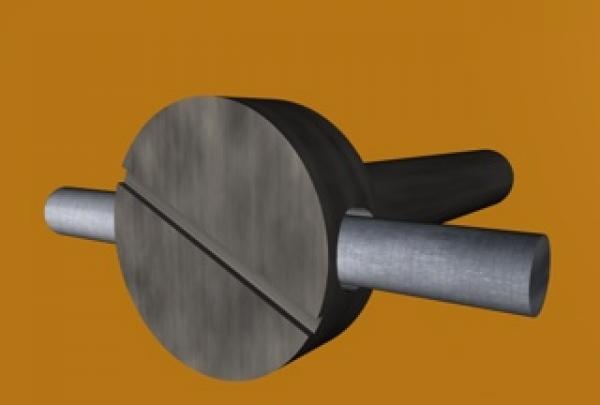

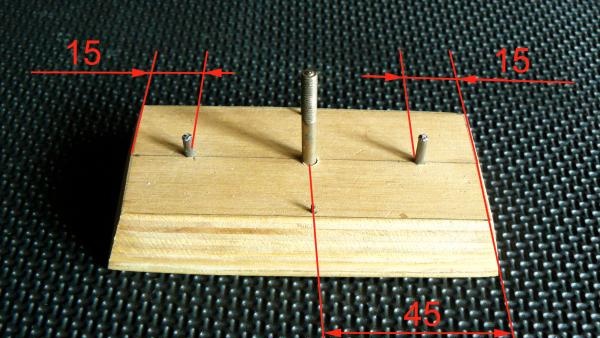

The grater consists of two parts - a base-iron and a pressing holder, which are connected with a screw and a wing nut.

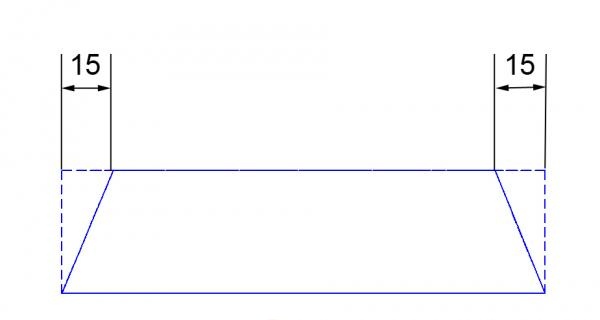

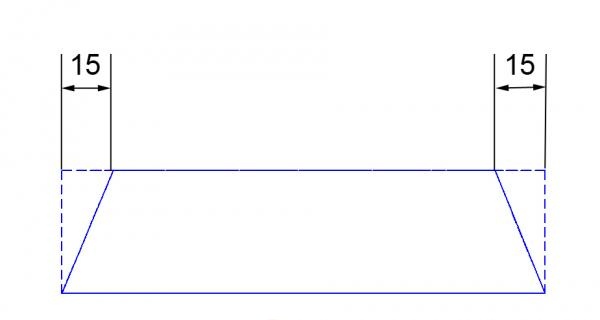

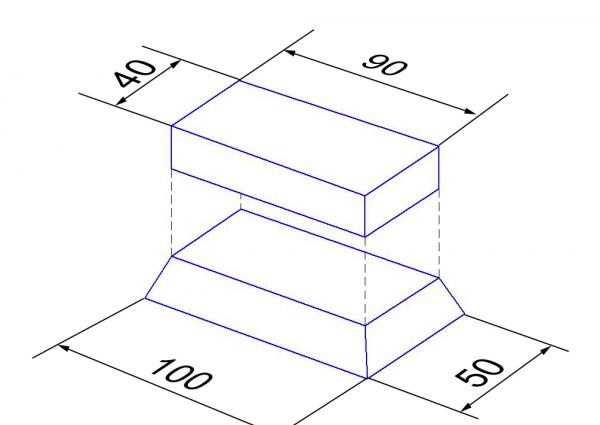

The base has equally beveled ends on all sides.

The pressing holder is equal in size to the upper plane of the base.

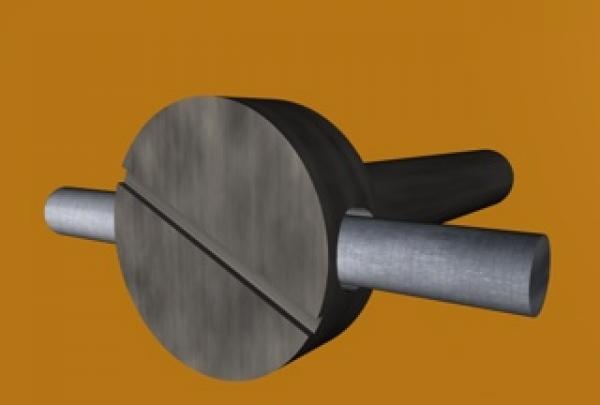

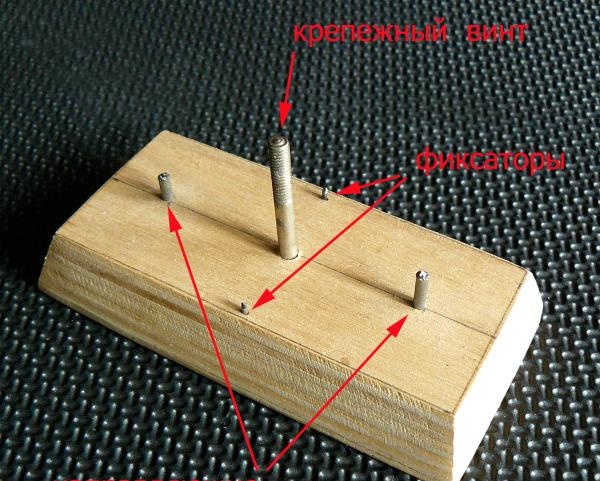

A screw is installed in the center of the base to secure the holder. The thumbscrew you use is the one you have available, so its diameter is not indicated. The length of the screw should be approximately 4 cm. Combine the base and holder and use a drill with a diameter slightly larger than the diameter of the screw to drill a through hole in the center.From the side of the base, drill a hole so that the screw head is completely hidden. Drill a hole in the head of the screw for a small nail to act as a stopper. We bite off the clove.

To recess the stopper nail, we make a slot on both sides of the hole for the screw head.

The slot can be selected with a grinder or a chisel. When the screw with stopper is installed in the slot with the slot, fill the cavity with epoxy resin or epoxy glue. After the resin has hardened, clean off the protruding part with sandpaper.

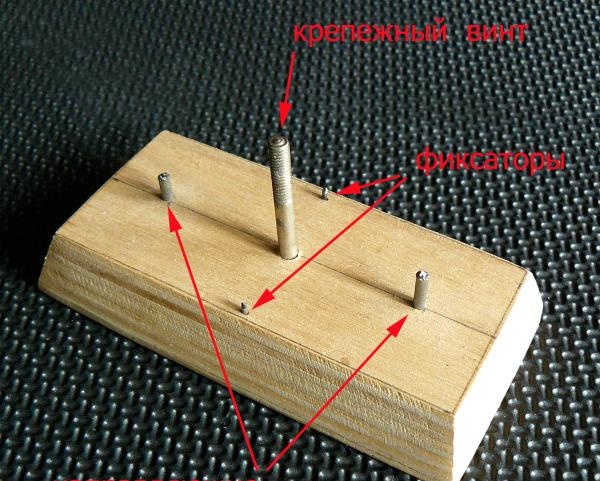

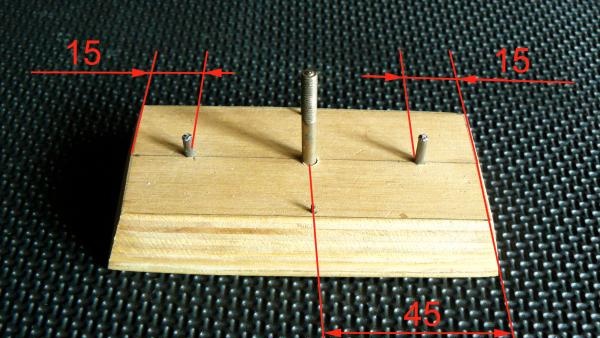

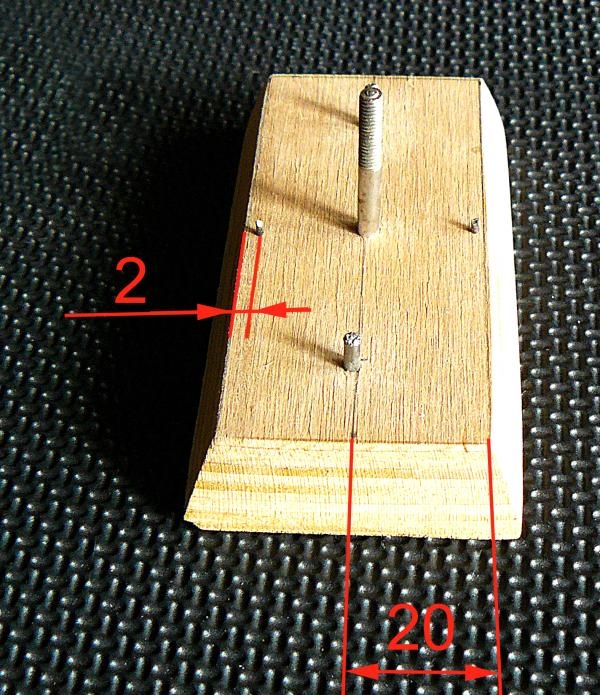

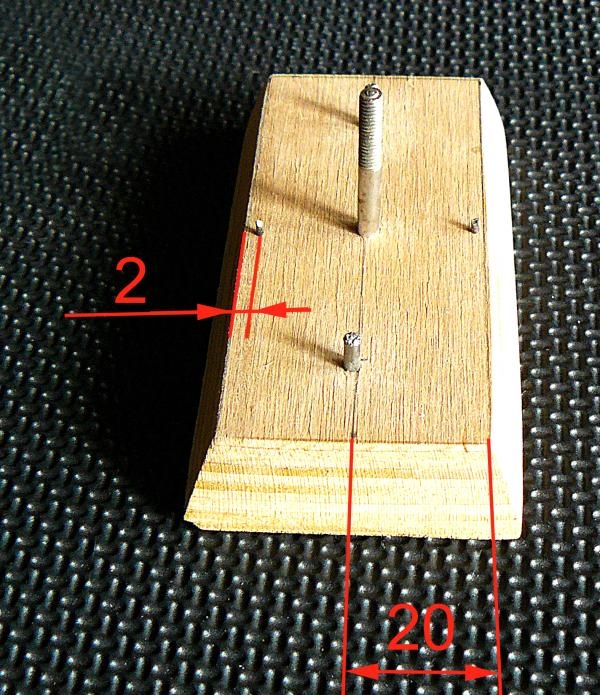

To ensure that the holder does not move, we make guides.

We install the holder exactly on the base, screw it with a thumbscrew through the washer. We select two nails for the guides (diameter 2 - 2.5 mm). We prepare two drills - with a diameter slightly smaller than the diameter of the nail and slightly larger. Using a “smaller” drill in the base through the holder, we drill a non-through hole for the guides. We drive the nails into the base into the holes obtained, and bite off the caps. In the holder from the base side, use a “large” drill to drill holes for free entry of the guides.

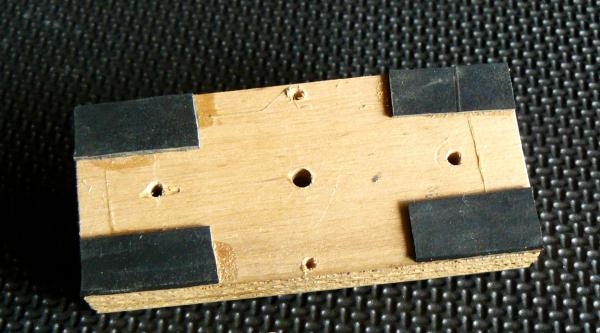

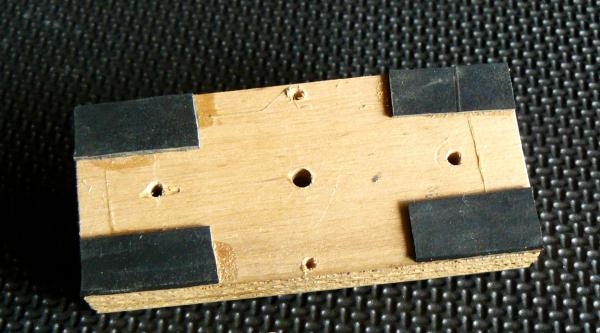

To securely press the sandpaper on the inner corners of the holder, glue pieces of thin rubber with Moment glue or something similar. We cut off the protruding parts of the rubber flush with the sides.

We install clamps for easy changing of sandpaper. These are thin nails (1 mm in diameter), which we drive along the long sides of the base.

We bite the cloves at a height of 2-3 mm from the plane of the base. We put the holder on; when you press lightly, pressed marks from the clamps remain on the inside of the holder. We widen and deepen the marks with an awl.

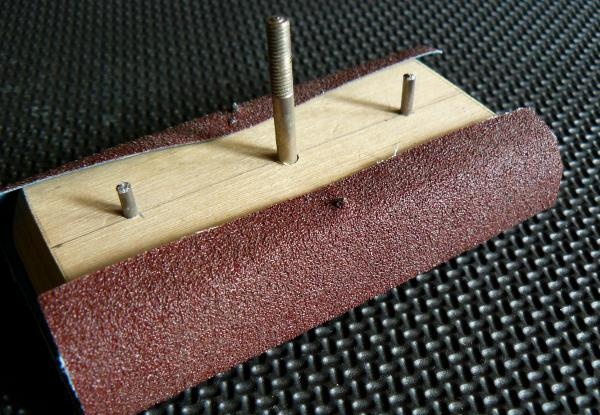

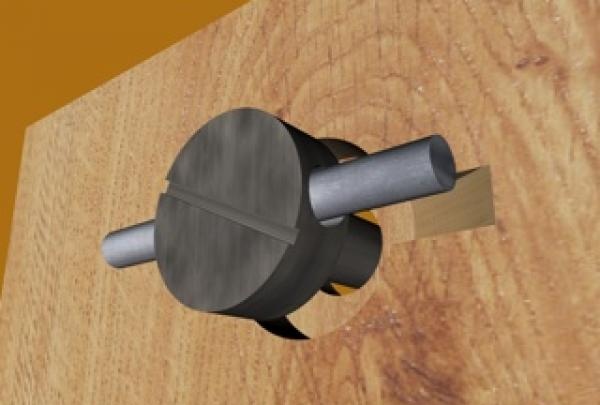

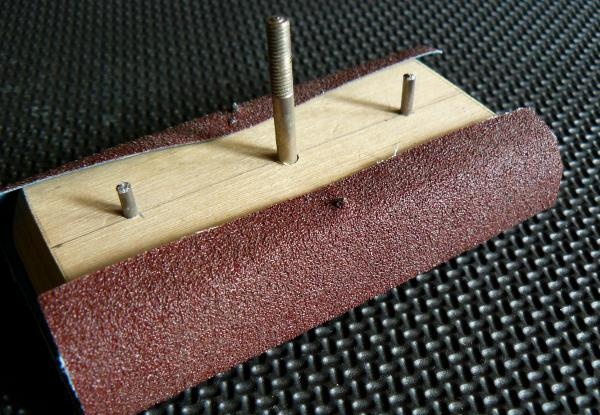

Putting on sandpaper. Cut out a piece of sandpaper measuring 10 x 10 cm.We pierce one edge in the middle with a fastener, wrap sandpaper around the base and attach it with a second fastener (pierce it).

We put the holder on top and clamp it with the thumb. The tool is ready for use. After wiping off the sandpaper, remove it, turn it 90 degrees, fix it on the grater again, and it will still be usable for some time.

For the manufacture of

You'll need:

- - pieces of multilayer plywood 16 mm thick;

- - screw with wing nut and washer;

- - thin cloves;

- - drill, drill bits;

- - pieces of thin rubber, glue;

- - epoxy resin or glue.

Manufacturing

The grater consists of two parts - a base-iron and a pressing holder, which are connected with a screw and a wing nut.

The base has equally beveled ends on all sides.

The pressing holder is equal in size to the upper plane of the base.

A screw is installed in the center of the base to secure the holder. The thumbscrew you use is the one you have available, so its diameter is not indicated. The length of the screw should be approximately 4 cm. Combine the base and holder and use a drill with a diameter slightly larger than the diameter of the screw to drill a through hole in the center.From the side of the base, drill a hole so that the screw head is completely hidden. Drill a hole in the head of the screw for a small nail to act as a stopper. We bite off the clove.

To recess the stopper nail, we make a slot on both sides of the hole for the screw head.

The slot can be selected with a grinder or a chisel. When the screw with stopper is installed in the slot with the slot, fill the cavity with epoxy resin or epoxy glue. After the resin has hardened, clean off the protruding part with sandpaper.

To ensure that the holder does not move, we make guides.

We install the holder exactly on the base, screw it with a thumbscrew through the washer. We select two nails for the guides (diameter 2 - 2.5 mm). We prepare two drills - with a diameter slightly smaller than the diameter of the nail and slightly larger. Using a “smaller” drill in the base through the holder, we drill a non-through hole for the guides. We drive the nails into the base into the holes obtained, and bite off the caps. In the holder from the base side, use a “large” drill to drill holes for free entry of the guides.

To securely press the sandpaper on the inner corners of the holder, glue pieces of thin rubber with Moment glue or something similar. We cut off the protruding parts of the rubber flush with the sides.

We install clamps for easy changing of sandpaper. These are thin nails (1 mm in diameter), which we drive along the long sides of the base.

We bite the cloves at a height of 2-3 mm from the plane of the base. We put the holder on; when you press lightly, pressed marks from the clamps remain on the inside of the holder. We widen and deepen the marks with an awl.

Putting on sandpaper. Cut out a piece of sandpaper measuring 10 x 10 cm.We pierce one edge in the middle with a fastener, wrap sandpaper around the base and attach it with a second fastener (pierce it).

We put the holder on top and clamp it with the thumb. The tool is ready for use. After wiping off the sandpaper, remove it, turn it 90 degrees, fix it on the grater again, and it will still be usable for some time.

Similar master classes

Particularly interesting

Comments (0)