The simplest DIY electric bike

Electric bicycles are in trend today. Even well-known car companies will present a model of a futuristic bicycle of the future, the operation of which is based on clean, cheap energy. Well, those who like to make things with their own hands also do not ignore this topic. Moreover, it is easier than ever to get spare parts for such devices.

Want to see what one of the most budget-friendly electric bikes looks like? In this article we will not only show it, but also tell you how it works and even how much you can buy spare parts for this miracle of technology.

This electric bicycle model is so simple that anyone, even a novice master, can assemble it. This is a great opportunity to test your creativity and crafting skills. Well, the reward will be a completely functional and practical electric bike based on a regular sports bike.

A special feature of these bicycles is the absence of a rear foot brake. They provide manual braking of the rear wheel using rubber pads and two multi-directional arc-shaped levers. Their compression occurs from the tension of a steel cable connected to the handle on the steering wheel. The principle of the driving module is based on the transmission of torque from the engine to the bicycle wheel through a rubber-coated auxiliary wheel.

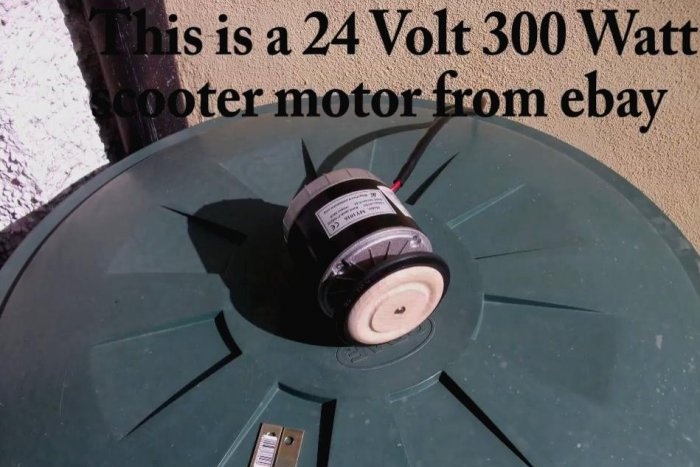

The engine has a regular cylindrical shape, to the body of which two metal mounting angles are welded. It is necessary to attach a wheel to the engine shaft, which will transmit torque when in contact with the tire of the bike.

In size it should not exceed the diameter of the engine body, so as not to overload it during operation. This could be a rubberized wheel for cargo carts, equipment or even furniture.

Using plates with holes and a small piece of board, we fasten the engine to the bicycle frame with bolts. We center it so that the auxiliary wheel has uniform contact with the bike tire.

To protect against dirt and dust, bicycles are equipped with a fender, which in our case is metal. We leave it in its place, making a hole with a grinder for the wheel of the device.

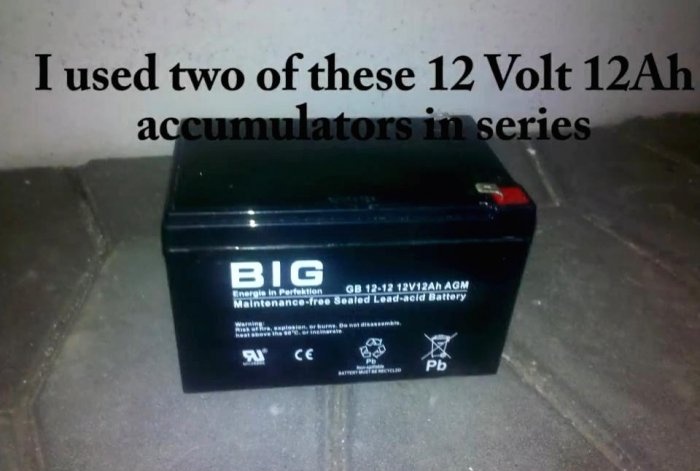

For power batteries, the author chose inexpensive 12 V lead batteries connected in series, suggesting as an option placing them in an old laptop bag. It can be attached behind the saddle, to the side of our device.

We take out the wires from the batteries, connect them in series with the engine and lead them to the toggle switch on the steering wheel. There are no controllers for adjusting the speed; I pressed the button - the full voltage of 24 V was supplied to the motor from the batteries. The simplest toggle switch can be mounted somewhere in a convenient place on the steering wheel.

To protect the driving mechanism of our electric bicycle, we can attach metal plates to both sides of the frame.

For safety, all solders and contact groups should be insulated with heat shrink, hot glue or electrical tape.

This design of an electric bicycle is really simple and practically does not require specialized maintenance. All you need is to charge the batteries in time and monitor the speed on the roads, because according to the author, it can reach 35 km/h!

Want to see what one of the most budget-friendly electric bikes looks like? In this article we will not only show it, but also tell you how it works and even how much you can buy spare parts for this miracle of technology.

This electric bicycle model is so simple that anyone, even a novice master, can assemble it. This is a great opportunity to test your creativity and crafting skills. Well, the reward will be a completely functional and practical electric bike based on a regular sports bike.

List of materials

- Sports bike or regular;

- A wheel for cargo carts or mobile equipment, you can easily make it yourself;

- 24V DC motor 300-350W;

- Lead battery 12 V/12 A - 2 pcs.;

- Toggle button;

- Hardware, wiring and some metal parts.

Let's start assembling the electric bike

A special feature of these bicycles is the absence of a rear foot brake. They provide manual braking of the rear wheel using rubber pads and two multi-directional arc-shaped levers. Their compression occurs from the tension of a steel cable connected to the handle on the steering wheel. The principle of the driving module is based on the transmission of torque from the engine to the bicycle wheel through a rubber-coated auxiliary wheel.

Engine preparation

The engine has a regular cylindrical shape, to the body of which two metal mounting angles are welded. It is necessary to attach a wheel to the engine shaft, which will transmit torque when in contact with the tire of the bike.

In size it should not exceed the diameter of the engine body, so as not to overload it during operation. This could be a rubberized wheel for cargo carts, equipment or even furniture.

Installing the engine on a bicycle

Using plates with holes and a small piece of board, we fasten the engine to the bicycle frame with bolts. We center it so that the auxiliary wheel has uniform contact with the bike tire.

To protect against dirt and dust, bicycles are equipped with a fender, which in our case is metal. We leave it in its place, making a hole with a grinder for the wheel of the device.

Electrics

For power batteries, the author chose inexpensive 12 V lead batteries connected in series, suggesting as an option placing them in an old laptop bag. It can be attached behind the saddle, to the side of our device.

We take out the wires from the batteries, connect them in series with the engine and lead them to the toggle switch on the steering wheel. There are no controllers for adjusting the speed; I pressed the button - the full voltage of 24 V was supplied to the motor from the batteries. The simplest toggle switch can be mounted somewhere in a convenient place on the steering wheel.

To protect the driving mechanism of our electric bicycle, we can attach metal plates to both sides of the frame.

For safety, all solders and contact groups should be insulated with heat shrink, hot glue or electrical tape.

This design of an electric bicycle is really simple and practically does not require specialized maintenance. All you need is to charge the batteries in time and monitor the speed on the roads, because according to the author, it can reach 35 km/h!

Watch the video of testing and assembling an electric bike

Similar master classes

Particularly interesting

Comments (8)