Replacing screwdriver batteries

One day, when I took my screwdriver out of the closet, I discovered that it didn’t work. The batteries were dead, the first thing I thought was and put the screwdriver on charge. But as soon as I connected the charger to the battery, it immediately showed the full charge of the battery. I connected a tester to check charging and it turned out that the batteries had high resistance, which meant they were failing.

After browsing the forums, I found out that the problem of failure of nickel-cadmium batteries used in screwdrivers is by no means new, but rather very common. In general, in addition to being cheap, these batteries are a plus for the manufacturer; they have a lot of shortcomings that become apparent during operation. This includes a short life cycle, low capacity, and short battery life.

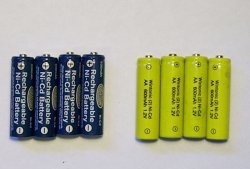

All forum members who are faced with a similar problem without hesitation boldly change nickel-cadmium batteries to lithium-ion ones, which is what I will do as well. They may be more expensive, but the screwdriver will work much longer and harder.

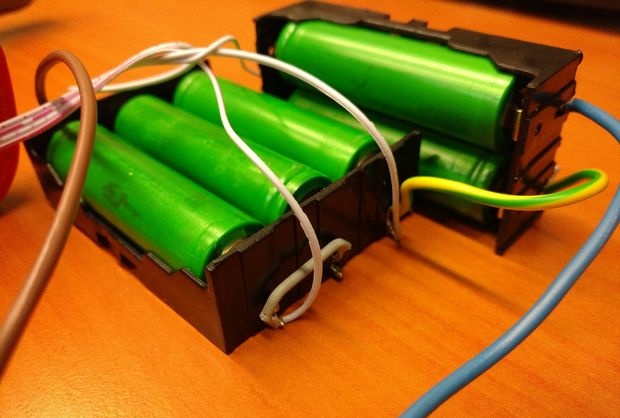

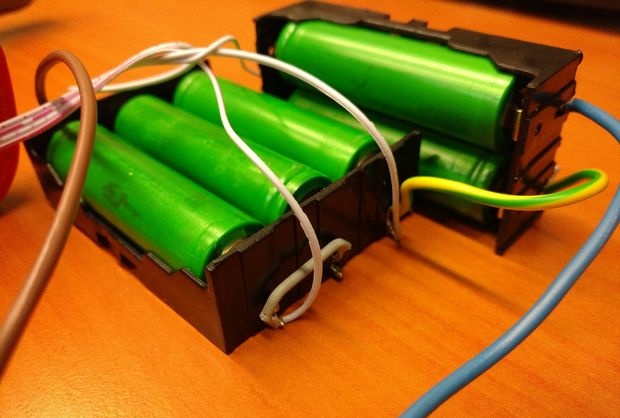

Without hesitation, I purchased 18650 lithium ion batteries. Since my screwdriver is 18-volt, and one battery produces 3.7 V, therefore, I needed 5 pieces. 5x3.7=18.5 V is what you need.

I also bought battery compartments, one for two batteries, the other for three. I connected everything in series. I took out the old batteries and replaced them with new ones.

This could be the conclusion, but as it turns out, I made a terrible mistake. The fact is that lithium-ion batteries cannot under any circumstances be charged in the same way as old batteries! This is even dangerous, as they can simply explode.

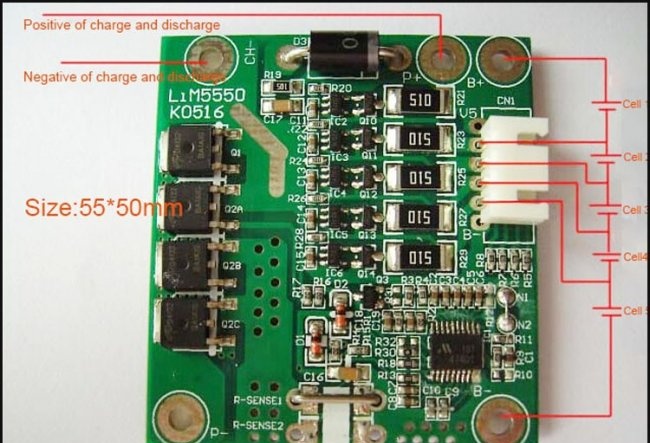

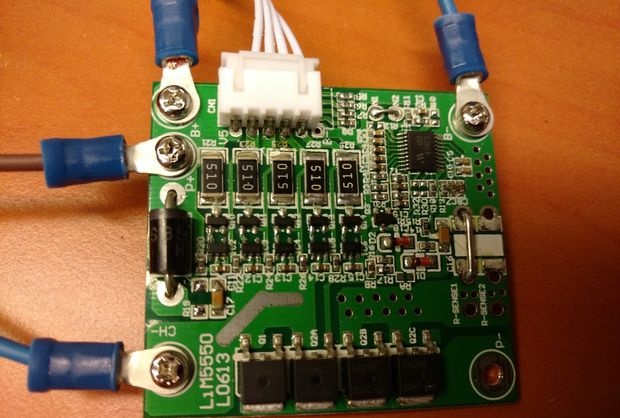

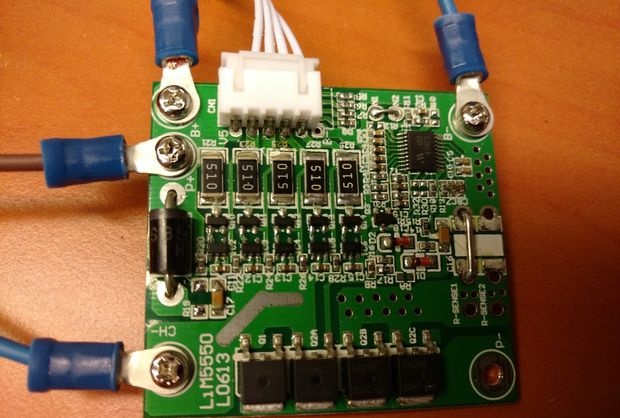

How then? It's not that complicated - you need a charging controller for lithium-ion batteries.

Lithium-ion batteries are very sensitive to overcharging and being discharged below normal - all these factors quickly damage them. This is perhaps their main disadvantage. But it’s easy to get rid of it by using a controller that will take over all the functions of monitoring and limiting dangerous modes and make the operation of the battery at a high-quality level.

Purchase links:

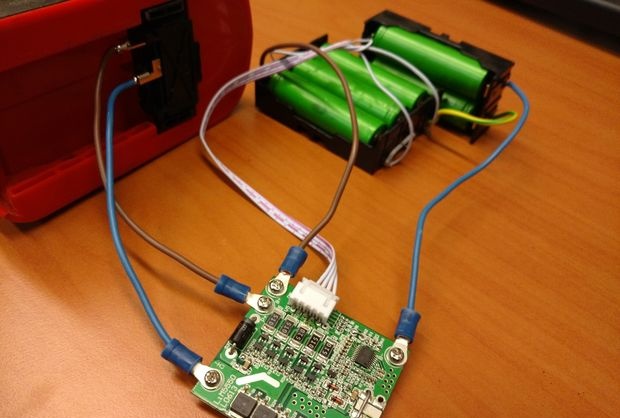

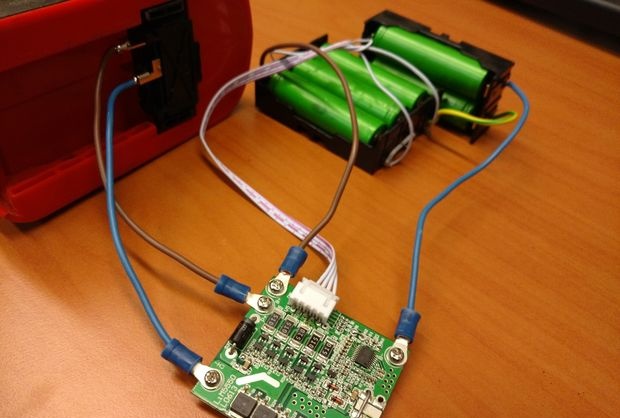

The batteries are also connected in series, except that each connection between the batteries is connected to the controller. As a result of this, the controller monitors the condition of each battery and prevents it from overcharging in the circuit.

I put together a diagram. Everything works perfectly.

Check video

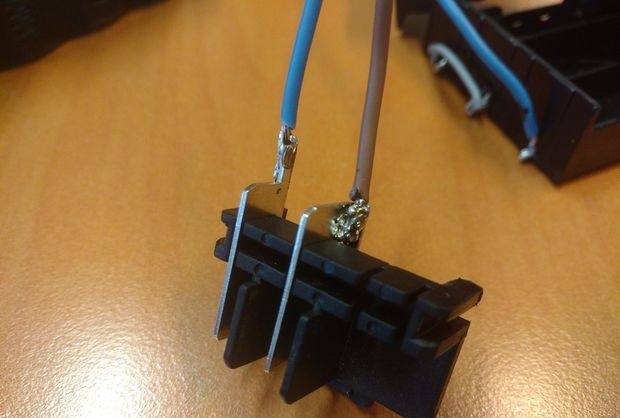

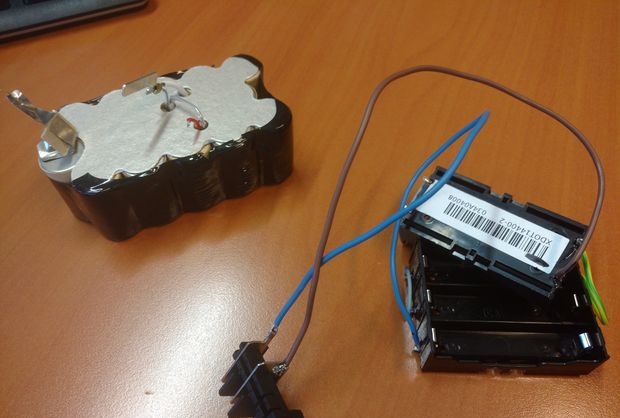

Since the controller was added, the battery compartments had to be abandoned, since there was sorely not enough space. Well, this is for the better, since the screwdriver is subject to vibration, and not tight contact could not have a very good effect in the future...

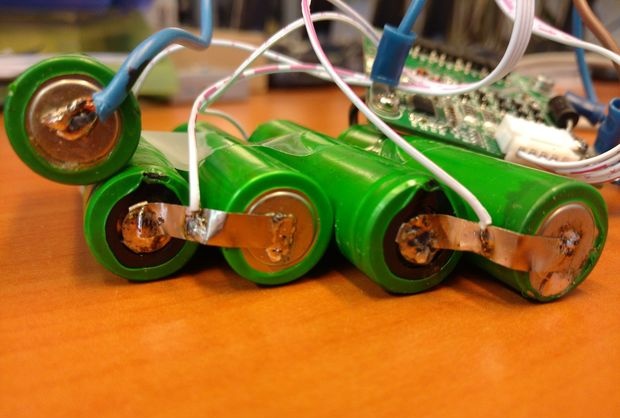

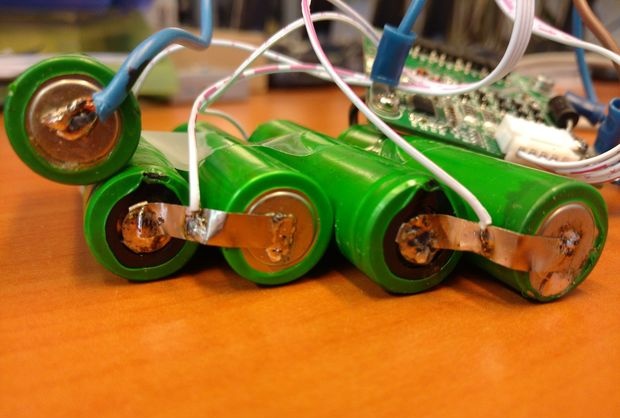

I decided to solder the batteries together.In general, lithium-ion batteries are very afraid of overheating and need to be connected by contact welding. But I don't have it. So I soldered everything with a soldering iron. If you do this, then teach: use only a powerful soldering iron of 40-60 watts. Solder with acid or active flux. And under no circumstances solder one connection for more than a second. If it doesn’t work the first time, it’s better to wait five minutes and try again.

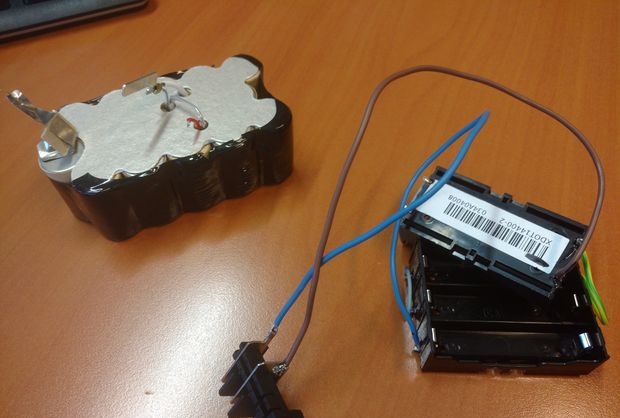

In the end I did this:

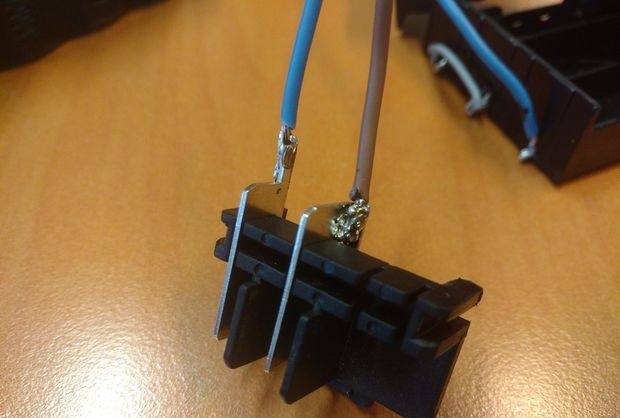

I soldered the circuit.

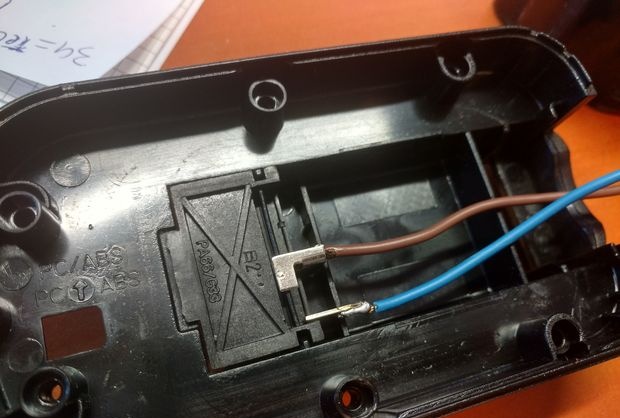

I glued the batteries together with tape and installed them diagonally into the battery compartment of the screwdriver.

Charging is in progress.

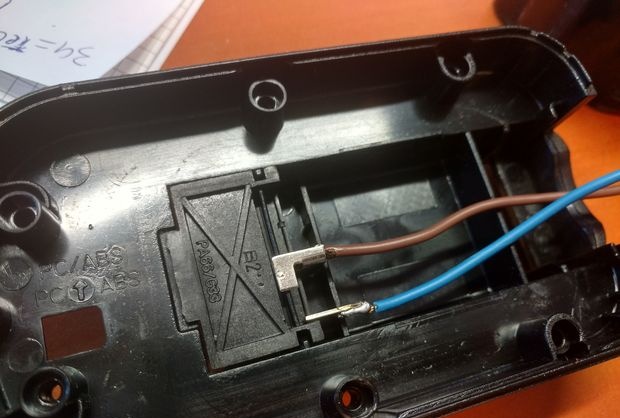

I soldered all the wires to the terminals and ended up with an updated battery for my old screwdriver, which I hope will serve me for many years.

Purchase links:

After browsing the forums, I found out that the problem of failure of nickel-cadmium batteries used in screwdrivers is by no means new, but rather very common. In general, in addition to being cheap, these batteries are a plus for the manufacturer; they have a lot of shortcomings that become apparent during operation. This includes a short life cycle, low capacity, and short battery life.

All forum members who are faced with a similar problem without hesitation boldly change nickel-cadmium batteries to lithium-ion ones, which is what I will do as well. They may be more expensive, but the screwdriver will work much longer and harder.

Replacing screwdriver batteries

Without hesitation, I purchased 18650 lithium ion batteries. Since my screwdriver is 18-volt, and one battery produces 3.7 V, therefore, I needed 5 pieces. 5x3.7=18.5 V is what you need.

I also bought battery compartments, one for two batteries, the other for three. I connected everything in series. I took out the old batteries and replaced them with new ones.

This could be the conclusion, but as it turns out, I made a terrible mistake. The fact is that lithium-ion batteries cannot under any circumstances be charged in the same way as old batteries! This is even dangerous, as they can simply explode.

How then? It's not that complicated - you need a charging controller for lithium-ion batteries.

Lithium-ion batteries are very sensitive to overcharging and being discharged below normal - all these factors quickly damage them. This is perhaps their main disadvantage. But it’s easy to get rid of it by using a controller that will take over all the functions of monitoring and limiting dangerous modes and make the operation of the battery at a high-quality level.

Purchase links:

- 18650 battery.

- Charge controller 5S 20A or specifically - HERE.

Charging controller connection diagram

The batteries are also connected in series, except that each connection between the batteries is connected to the controller. As a result of this, the controller monitors the condition of each battery and prevents it from overcharging in the circuit.

I put together a diagram. Everything works perfectly.

Check video

Screwdriver battery assembly

Since the controller was added, the battery compartments had to be abandoned, since there was sorely not enough space. Well, this is for the better, since the screwdriver is subject to vibration, and not tight contact could not have a very good effect in the future...

I decided to solder the batteries together.In general, lithium-ion batteries are very afraid of overheating and need to be connected by contact welding. But I don't have it. So I soldered everything with a soldering iron. If you do this, then teach: use only a powerful soldering iron of 40-60 watts. Solder with acid or active flux. And under no circumstances solder one connection for more than a second. If it doesn’t work the first time, it’s better to wait five minutes and try again.

In the end I did this:

I soldered the circuit.

I glued the batteries together with tape and installed them diagonally into the battery compartment of the screwdriver.

Charging is in progress.

I soldered all the wires to the terminals and ended up with an updated battery for my old screwdriver, which I hope will serve me for many years.

Purchase links:

- 18650 battery.

- Charge controller 5S 20A or specifically - HERE.

Similar master classes

Particularly interesting

Comments (4)