Pocket stove

Hiking in nature is relevant at any time of the year. Hunting and fishing are a real hobby and hobby for many. And who among us doesn’t like to just wander through the forest or go with the family to a river or lake. This is where heating devices become relevant, on which you can warm a cup of tea or even cook food. Stores today are filled with such devices. But why spend extra money when you can make a simple and effective stove-heater yourself from a piece of plasterboard profile.

In fact, such stoves or heating stands were first made by the German inventor and businessman Erich Schumm back in the 30s of the last century. He is also credited with creating pelletized fuel, which we all know as “dry alcohol.” Stoves like ours were widely used by German soldiers during World War II. But what's really surprising is that Esbit still makes them. This is a truly simple and ingenious invention that remains relevant today!

This homemade product can be classified as a simple and ingenious lifehack invention that can be made in 5-10 minutes from literally anything.It weighs nothing at all and will not burden a real tourist at all. The housing is designed in such a way that dry fuel and even matches can easily fit into it. Well, why are we praising the product here, let’s get down to business.

To make such a heater, we will need:

You can cut tin with a grinder (angle grinder) or metal scissors. For riveting you will need universal pliers. It will be most convenient to make holes with a screwdriver or a drill and a drill of the appropriate diameter, and bend the sheet metal with pliers.

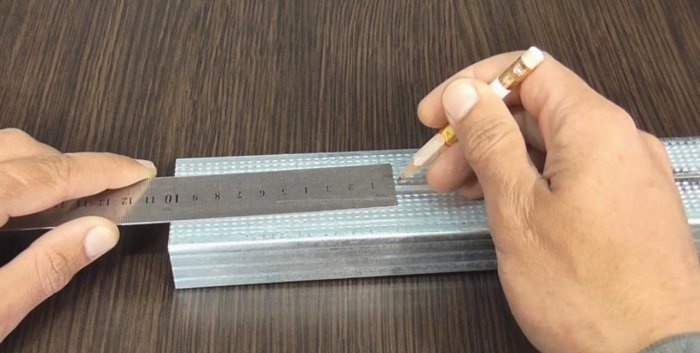

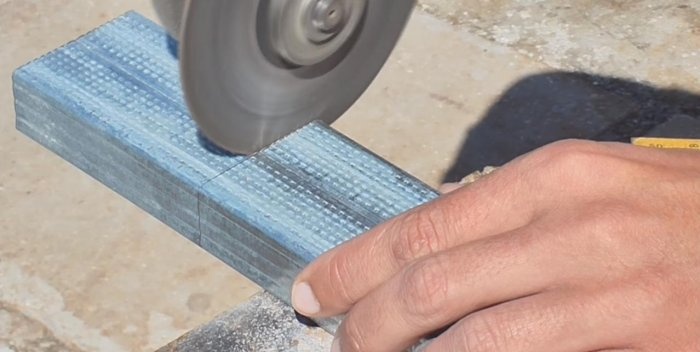

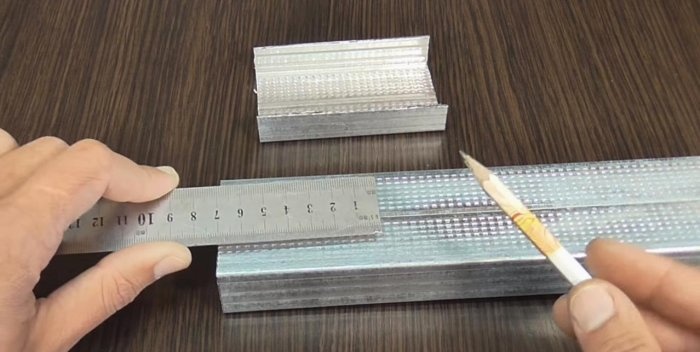

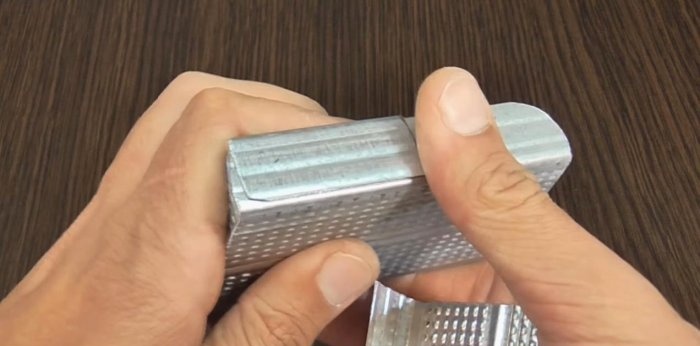

We mark a piece of plasterboard profile 10 cm long and cut it off. The curved ends of the profile shelves will interfere with the movement of the covers, so we also remove them along the first curved mark on the edge. We clean the burrs with sandpaper or a grinding wheel for an angle grinder.

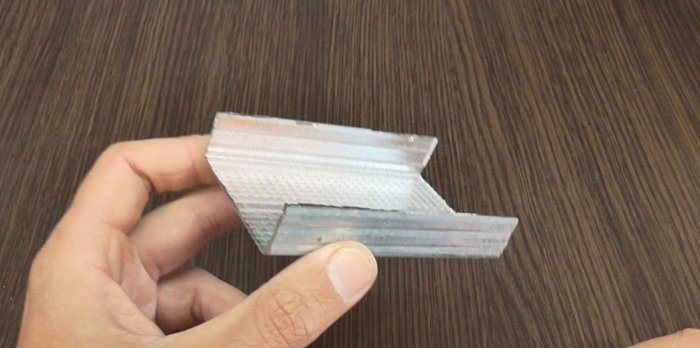

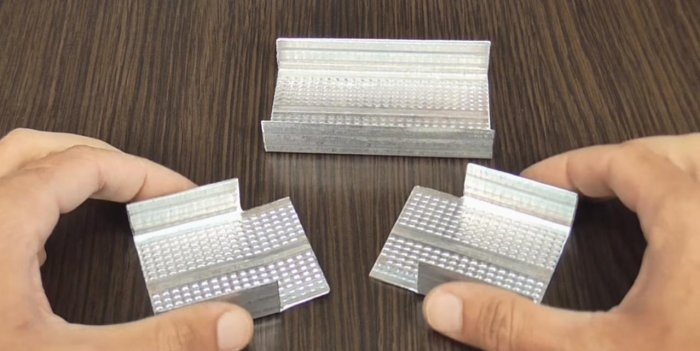

From the same profile we make covering covers 7 cm long, and we also cut off the curved ends of the shelves. Mark 2 cm from one of the edges of the lid. Marks must be placed on both profile flanges. We cut the edge along them and remove it to the very plane.

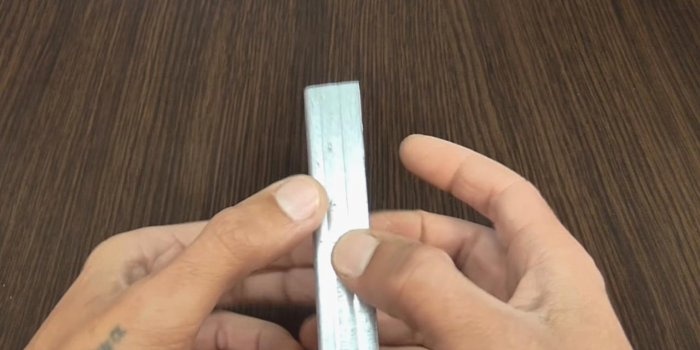

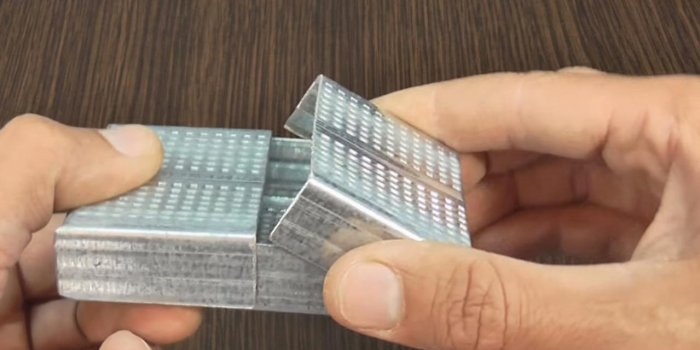

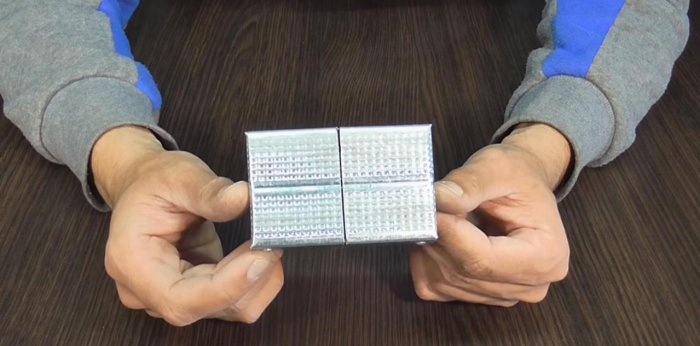

Use pliers to bend the end edge of the lids. On the main profile - the bottom of our stove - we cut the ends of the ribs in the shape of a neat semicircle. Place the lids on the base. The joint in the middle between two profile fragments should be minimal.

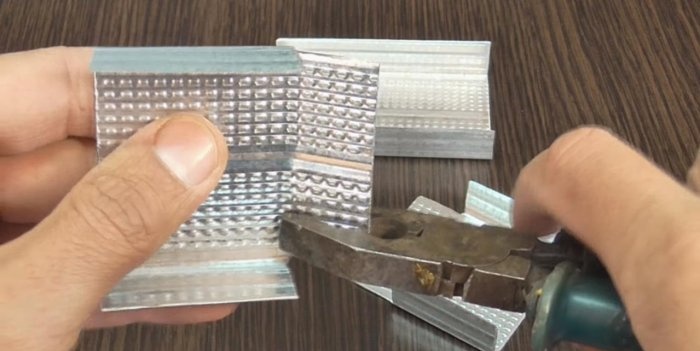

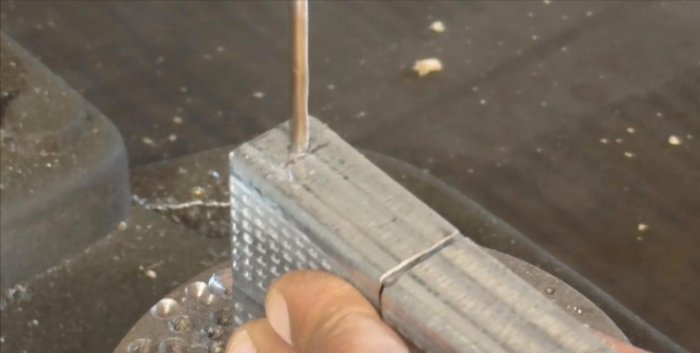

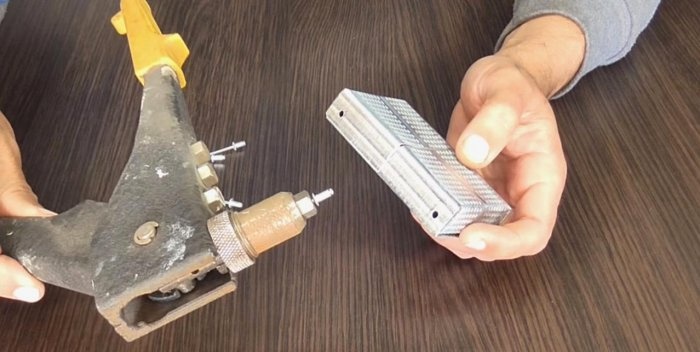

Pressing the ends of the covers tightly, we place the stove body on its edge and make holes for rivets in the four corners. To prevent the ends of the profile from bending during drilling, they can be tightened with pliers.

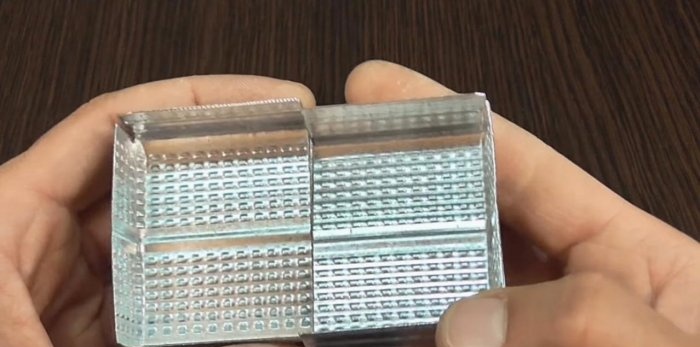

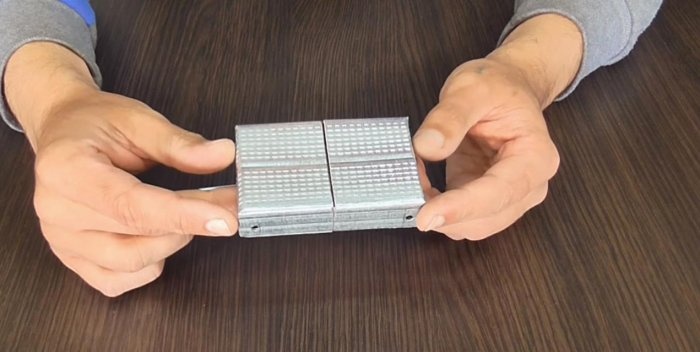

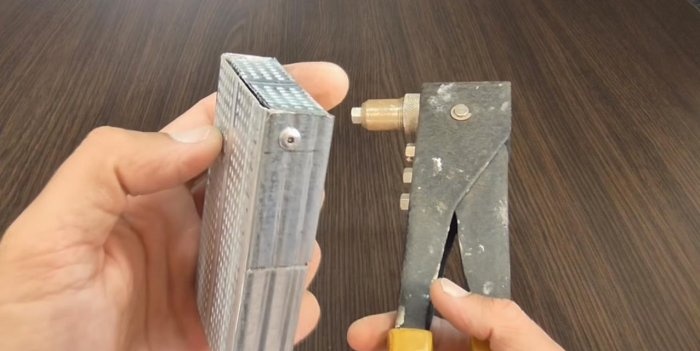

We insert rivets into the holes and crimp them with special pliers. That's it, the heater stove is ready, it's time to test.

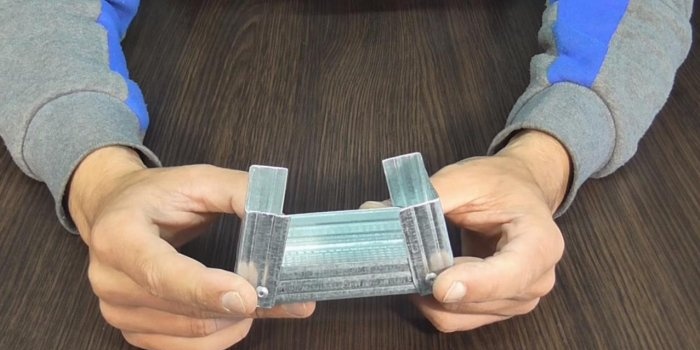

We insert a tablet of dry alcohol inside, and also adjust the metal mug on top, adjusting the span of the lids to its size. We light the fuel and enjoy some nice hot drinks. By the way, such a stove is capable of heating half a liter of water from one tablet of dry fuel in just 8-12 minutes!

To trim a profile with a grinder, use a vice to clamp the parts, otherwise they can play in your hands and cause injury to your hands.

Choose a plasterboard profile made from thicker sheet metal. Such material will be more durable, especially in the fuel combustion zone. By the way, the original Esbit stoves are made of titanium, which is practically resistant to corrosion and deformation.

Additional holes or slits in the bottom, which can be made near the middle, will help improve the operation of the stove. Thanks to them, oxygen will get inside and promote fuel combustion.

The convenience of such a heater is that it can use various types of fuel - from dry alcohol to gasoline or kerosene. For this, it is enough to adapt a small container that would fit inside the stove and create sufficient combustion to heat water or food. Otherwise, this device is really reliable and, probably, the most inexpensive help for lovers of outdoor activities.

In fact, such stoves or heating stands were first made by the German inventor and businessman Erich Schumm back in the 30s of the last century. He is also credited with creating pelletized fuel, which we all know as “dry alcohol.” Stoves like ours were widely used by German soldiers during World War II. But what's really surprising is that Esbit still makes them. This is a truly simple and ingenious invention that remains relevant today!

This homemade product can be classified as a simple and ingenious lifehack invention that can be made in 5-10 minutes from literally anything.It weighs nothing at all and will not burden a real tourist at all. The housing is designed in such a way that dry fuel and even matches can easily fit into it. Well, why are we praising the product here, let’s get down to business.

What is a homemade miracle stove made of?

To make such a heater, we will need:

- A piece of plasterboard steel profile CD 60x28, length – 25-30 cm;

- Construction rivets for sheet metal;

- Dry alcohol or other suitable heater.

You can cut tin with a grinder (angle grinder) or metal scissors. For riveting you will need universal pliers. It will be most convenient to make holes with a screwdriver or a drill and a drill of the appropriate diameter, and bend the sheet metal with pliers.

Let's start making the oven

We mark a piece of plasterboard profile 10 cm long and cut it off. The curved ends of the profile shelves will interfere with the movement of the covers, so we also remove them along the first curved mark on the edge. We clean the burrs with sandpaper or a grinding wheel for an angle grinder.

From the same profile we make covering covers 7 cm long, and we also cut off the curved ends of the shelves. Mark 2 cm from one of the edges of the lid. Marks must be placed on both profile flanges. We cut the edge along them and remove it to the very plane.

Use pliers to bend the end edge of the lids. On the main profile - the bottom of our stove - we cut the ends of the ribs in the shape of a neat semicircle. Place the lids on the base. The joint in the middle between two profile fragments should be minimal.

Pressing the ends of the covers tightly, we place the stove body on its edge and make holes for rivets in the four corners. To prevent the ends of the profile from bending during drilling, they can be tightened with pliers.

We insert rivets into the holes and crimp them with special pliers. That's it, the heater stove is ready, it's time to test.

We insert a tablet of dry alcohol inside, and also adjust the metal mug on top, adjusting the span of the lids to its size. We light the fuel and enjoy some nice hot drinks. By the way, such a stove is capable of heating half a liter of water from one tablet of dry fuel in just 8-12 minutes!

Practical advice

To trim a profile with a grinder, use a vice to clamp the parts, otherwise they can play in your hands and cause injury to your hands.

Choose a plasterboard profile made from thicker sheet metal. Such material will be more durable, especially in the fuel combustion zone. By the way, the original Esbit stoves are made of titanium, which is practically resistant to corrosion and deformation.

Additional holes or slits in the bottom, which can be made near the middle, will help improve the operation of the stove. Thanks to them, oxygen will get inside and promote fuel combustion.

Conclusion

The convenience of such a heater is that it can use various types of fuel - from dry alcohol to gasoline or kerosene. For this, it is enough to adapt a small container that would fit inside the stove and create sufficient combustion to heat water or food. Otherwise, this device is really reliable and, probably, the most inexpensive help for lovers of outdoor activities.

Watch the video

Similar master classes

Particularly interesting

Comments (5)