Do-it-yourself bathtub restoration with liquid acrylic

Liquid acrylic is a modern material with which you can perform high-quality bathtub restoration with your own hands. It consists of a base having a fairly high density and a hardener. Can be used for the restoration of steel, cast iron and acrylic bathtubs.

Materials and tools

To restore the bathtub, you will need bulk liquid acrylic, cleaning and degreasing products for plumbing fixtures, and soda. Please note that liquid acrylic is sold in containers designed for bathtub sizes - 1.2, 1.5 or 1.7 m.

You need to prepare a tool for work:

- grinder;

- drill;

- whisk attachment;

- pliers;

- sandpaper of various grain sizes;

- rubber spatula;

- respirator;

- vacuum cleaner;

- sponge;

- gloves;

- flashlight.

When using a drill to sand the surface of the bathtub, you will need a special attachment.

Note: a hair dryer and a utility knife will be useful for removing non-factory enamel if the bathtub has already been restored with it.

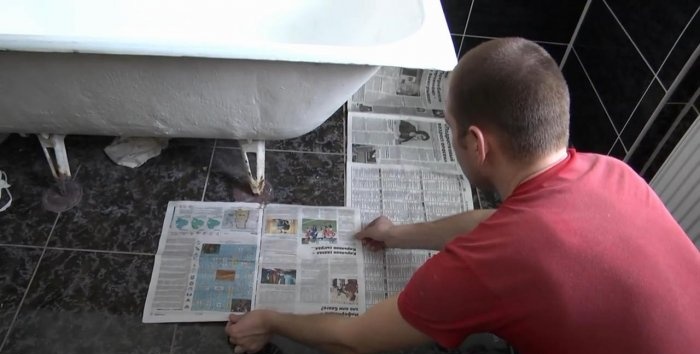

You also need polyethylene to protect the floor and walls (you can use rags or newspapers).

Preparing the bath

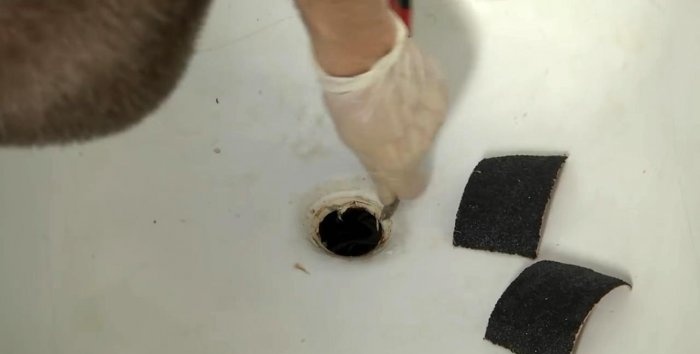

The appearance and service life of the applied coating will depend on the quality of preparation. First, the overflow and drain are removed. Using a grinder or a drill with a grinding attachment, you need to carefully treat the surface of the bathtub. For this purpose, sandpaper for rough work 40-N or 32-N is used (according to GOST 3647-80). Emery will also help remove any water deposits that have formed. The surface after sanding should be rough to ensure good adhesion of liquid acrylic.

Note: non-factory enamel, previously applied to restore the bathtub, is removed with a utility knife after heating with a hairdryer.

The bathtub needs to be cleaned and any remaining debris removed. Then the surface is treated with a plumbing cleaner - the poured product must be spread with a sponge over the entire surface of the bathtub, including the installation location of the removed overflow.

The bath is washed again and left to dry. After drying, the next important stage of work begins - degreasing. Soda is poured into the bath and thoroughly rubbed over the entire surface with coarse sandpaper.

Perhaps degreasing will need to be done not once, but two or three times. You must work with gloves. Then the bath is thoroughly washed with a stream of water from the shower.

Before starting the next stage, you need to remove the siphon.

The installation site of the siphon must be cleaned, degreased and rinsed from soda residues.

The mixer and shower are covered with a bag and secured with tape - water should not get on the applied layer of liquid acrylic until it dries completely. The tiles and shelves above the bathtub are cleaned of dust particles with a cloth. Do not allow sanding dust to get on the acrylic.

After completing this stage, the bath should be thoroughly dried with a hairdryer.Particular attention is paid to places where water can collect: the joints of the tiles and the bathtub, under the side, which is installed at the junction of the tiles and the bathtub. It is better to remove the rim and carry out the restoration of the bathtub without it. The cement joints at the junction with the bathroom can be dried well with a hairdryer.

To eliminate defects in factory enamel (cracks, chips), use quick-drying automotive putty.

The composition is stirred and applied to the damaged areas with a rubber spatula, after which it is allowed to dry.

While the putty dries, cover the floor under the bathtub and the tiles at the joints with polyethylene or newspapers, which are secured with tape.

This way, when pouring liquid acrylic, it will not spoil floor and wall tiles.

After the putty has dried, these places are covered with fine sandpaper. Use a vacuum cleaner to remove dust particles from the bathtub.

Use a degreasing agent (acetone) to wipe the areas where cracks and chips have been putty. You should also wipe the installation areas of the overflow and siphon with acetone. Place a container under the drain hole (you can use a cut plastic bottle). Excess liquid acrylic will drain into this container.

Coating

After completing the preparatory work, they begin to prepare liquid acrylic. The hardener is added to the material in parts and thoroughly mixed using a drill with a whisk attachment.

It is necessary to achieve complete mixing of the two components, not forgetting about the material in the corners and at the bottom of the jar with liquid acrylic. Otherwise, the layer of applied acrylic will dry unevenly. You need to stir the mixture for 10 minutes.

Important! Do not forget about the pot life of the finished mixture, which is indicated on the packaging. During this time, you need to completely complete the work.

Before pouring the composition is allowed to stand for 5-10 minutes.To work, you will need a plastic container into which acrylic is poured. You can use a trimmed and well-wiped hardener bottle. The work is performed wearing medical gloves.

Note: adding coloring paste will allow you to obtain the desired color of the composition. Color paste by weight should not exceed 3% of the total mass of the composition.

The composition is poured around the perimeter of the bath from top to bottom.

Going lower, help yourself with a rubber spatula, which is used to rub the acrylic into the surface of the bathtub. Having achieved complete coverage with liquid acrylic, use a spatula to make zigzag movements along the bottom of the bath. Then the composition is leveled with even movements from the wall towards the drain.

The bath is left for 5 minutes. Turn off the light and use a flashlight to check the surface of the bath for defects or irregularities (smudges) that need to be leveled with a spatula.

Important! Air bubbles may have formed when mixing the composition. To remove these bubbles, the surface of the bath is quickly blown with a hairdryer at low speeds.

After 10 minutes, use a flashlight to check the surface again. The bathtub can be used 24-48 hours after complete drying. Until this point, the bathroom must be closed. The drying time of the composition depends on the technical characteristics of the material and the temperature in the room.

Note: Some modern liquid acrylics take 12-16 hours to dry.

The result of the work

As a result of the work done, you will receive a completely restored bathtub with a beautiful appearance, which is guaranteed to last at least 10 years. After each use, the bathtub should be washed with special acrylic care products, dishwashing detergents or liquid soap.

Advantages and disadvantages

Advantages of bathtub restoration with liquid acrylic:

- long service life;

- beautiful appearance;

- smooth surface;

- excellent performance characteristics, primarily mechanical strength;

- possibility of repeated restoration in the future.

A bathtub after restoration will be practically in no way inferior to a new bathtub.

The disadvantages of this technology include:

- the long time required for the surface to dry completely;

- a specific smell when applying and drying liquid acrylic;

- the need to purchase bath care products.

Tricks at work

A high-quality bathtub surface will be obtained by applying the composition in an even, thick layer. Acrylic should flow down on its own. Determine by eye the middle of the side slopes and pour a second portion of the composition onto them. The remaining material is poured to the bottom. This way the entire surface of the bath will be covered with a thick layer of acrylic.

Watch the video

Similar master classes

Particularly interesting

Comments (0)