Drill sharpening device

One of the main parameters of a twist drill is the tip angle, which for durable metals (steel, cast iron, hard bronze, titanium, etc.) is approximately 120 degrees.

Deviation of this angle more or less from the nominal value makes it difficult for the drill to operate effectively. In the first case, productivity drops and the tool overheats; in the second, the drill may simply break, unable to withstand the excessive load.

In order to comply with the sharpening parameters without special devices, you must have high qualifications and experience as a tool sharpener. Well, it will be almost impossible for a non-specialist, especially in domestic conditions, to do this.

But, having some tools and simple materials, you can make a not very complicated, but reliable device for sharpening the corner at the tip of a twist drill for hard metal.

What you might need to work on the device

To do this you will need the following tools:

- calipers;

- marker;

- metal vice;

- Bulgarian;

- pliers;

- welding machine;

- sharpening machine with an emery wheel.

Materials you need to have on hand for work:

- regular hex nut;

- castle nut;

- bolt of the same size and thread as the nuts;

- twist drill that requires sharpening.

Manufacturing process

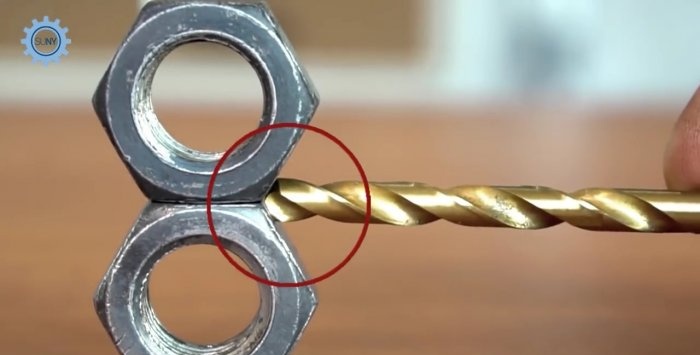

The peculiarity of a hex nut is that any two adjacent faces meet at an angle of 120 degrees. The apex angle of a twist drill for working on hard metals is approximately the same size. This random coincidence can be used to make a tool for sharpening a twist drill.

To do this, using a caliper and a marker on the nut, mark the cutting lines to create a triangular slot, symmetrical with respect to the diagonal connecting two opposite corners of the nut. The drill will be placed longitudinally into it before the sharpening process.

To cut out the intended triangular groove in the nut, it is clamped in a vice and, using a grinder, cuts are made along pre-drawn lines. You can use pliers to remove sawed off pieces of the nut.

Next, take a castle nut and weld it with its base to the first nut on the side of the cut groove. Moreover, it is necessary to maintain their absolute alignment, because when small-diameter drills are sharpened, the bolt, having passed through the castle nut, will begin to screw into the lower nut in order to firmly clamp the drill in its groove.

Now we screw the corresponding bolt into the castle nut, which will securely press the drill placed in the sharpening groove on the sandpaper of the sharpening machine.

All that remains is to sharpen the drill on an emery wheel, using the edges of the bottom nut as a template.

To do this, we simply grind the protruding part of the drill flush with the edges of the nut, which even a first-year vocational school student can easily cope with.

After sharpening is completed, the bolt is loosened, the drill is removed from the homemade device and can be used for its intended purpose.

Additions and improvements

During the welding process of nuts, liquid metal may splash onto the threads of castle and regular nuts. To eliminate this nuisance, it is necessary to screw a bolt into them and thereby protect the thread.

Since it will not be possible to cover all the diameters of drills with one device, at least two template clamps will be required: one for small drills, the other for large products. Accordingly, in the first case the nuts will be small in size, and in the second - large.

Watch the video

Similar master classes

How to quickly make a device for sharpening drills

How to properly sharpen a drill by hand

The simplest device for sharpening knives at 30 degrees

A simple device for checking the correct angle when manually

How to drill a quick cutter - P18 steel

A simple tool for sharpening knives at a fixed angle

Particularly interesting

Comments (53)