How to restore a knife if the handle breaks off

Sometimes the handle linings of knives break off, especially if they are made of plastic. It’s a pity to throw away a knife plate, especially when the blade can still serve for a long time.

First, we will discuss two ideas for restoring a knife handle, and then we will try to make one of them a reality. Any person holding cutting tools, a hammer, pliers and a brush can handle this kind of work.

If the shank is thick enough, then you can take a piece of hard wood, make a cut in it or drill a hole and insert the shank into it with tension. This type of fastening of the handle to the shank is called mounted. With a thin shank, this method of securing the handle will not be very reliable.

For such a case, it is better to make the handle from two identical halves and secure them to the shank with rivets, pins or furniture ties. This method, called riveted or overhead, seems to be the best here.

We prepare the knife for restoration by completely removing all remnants of the previous handle from the shank, and putting it in order.

Let's prepare the necessary materials:

Required equipment and tools:

The dimensions of the handle depend on the length of the blade and shank, but the thickness of the pads should not be less than 6-7 mm, otherwise it is difficult to ensure the strength of the handle and ease of use. The sequence of individual steps is also not critical.

1. Cut two pieces of equal length from the prepared wooden block (future linings or cheeks of the handle).

2. Using pliers or a hacksaw, we separate the pins from the rod along a length slightly larger than the total thickness of the handle. At the end of the work, they can be riveted and the linings can be firmly connected to each other and to the shank. The ends of the pins are rounded for safety and ease of installation in the holes.

3. Using the shank with the heel as a sample, we place them on the cheek blanks, outline the front contour and the place where the hole is drilled. We carry out drilling and processing of the linings on the side of the blade according to the marks, since after assembling the knife it will not be easy to do this, especially if they are complex in configuration. We insert the pin into the hole and make sure that it matches in diameter and length.

4. We cut the veneer along the contour, placing a piece of it between the overlays, and removing the excess with a Stanley knife.

5. Apply epoxy resin to the outer surfaces of the linings, inserting a pin into the hole in advance, and glue the veneer. After making sure that there is no displacement, we assemble the knife plate, both pads with glued veneer along with the pin and clamp everything in a vice until the epoxy resin has completely cured.

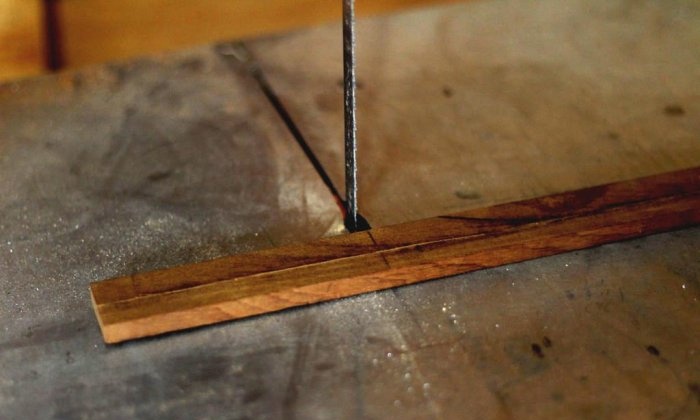

6. Pre-shape the handle using first a band saw, a carpet knife, then a grinder and coarse sandpaper.

7. Bring the shape and smoothness of the surface of the handle to the required level with sanding paper of decreasing grit. We finally polish the surface of the handle, wipe it with a clean rag and apply a transparent waterproof varnish. This will protect our kitchen knives from moisture.

8. The knife is completely ready for use. It turned out to be functional and beautiful.

If the overlays are covered with veneer, then only the ends can be machined, otherwise the veneer coating can be damaged.

Original article in English

First, we will discuss two ideas for restoring a knife handle, and then we will try to make one of them a reality. Any person holding cutting tools, a hammer, pliers and a brush can handle this kind of work.

If the shank is thick enough, then you can take a piece of hard wood, make a cut in it or drill a hole and insert the shank into it with tension. This type of fastening of the handle to the shank is called mounted. With a thin shank, this method of securing the handle will not be very reliable.

For such a case, it is better to make the handle from two identical halves and secure them to the shank with rivets, pins or furniture ties. This method, called riveted or overhead, seems to be the best here.

We prepare the knife for restoration by completely removing all remnants of the previous handle from the shank, and putting it in order.

What do we need for work?

Let's prepare the necessary materials:

- knife plate – blade with a shank (recovery item);

- veneer of red or similar quality wood;

- a block of hardwood or multi-layer high-quality plywood;

- epoxy resin;

- metal rod (preferably copper or aluminum, but steel is also possible);

- transparent waterproof varnish.

Required equipment and tools:

- hacksaw for wood and metal;

- Stanley knife (carpet knife);

- pliers or pliers;

- drilling machine or electric drill;

- bench vice;

- grinder and sandpaper.

The process of making a knife handle

The dimensions of the handle depend on the length of the blade and shank, but the thickness of the pads should not be less than 6-7 mm, otherwise it is difficult to ensure the strength of the handle and ease of use. The sequence of individual steps is also not critical.

1. Cut two pieces of equal length from the prepared wooden block (future linings or cheeks of the handle).

2. Using pliers or a hacksaw, we separate the pins from the rod along a length slightly larger than the total thickness of the handle. At the end of the work, they can be riveted and the linings can be firmly connected to each other and to the shank. The ends of the pins are rounded for safety and ease of installation in the holes.

3. Using the shank with the heel as a sample, we place them on the cheek blanks, outline the front contour and the place where the hole is drilled. We carry out drilling and processing of the linings on the side of the blade according to the marks, since after assembling the knife it will not be easy to do this, especially if they are complex in configuration. We insert the pin into the hole and make sure that it matches in diameter and length.

4. We cut the veneer along the contour, placing a piece of it between the overlays, and removing the excess with a Stanley knife.

5. Apply epoxy resin to the outer surfaces of the linings, inserting a pin into the hole in advance, and glue the veneer. After making sure that there is no displacement, we assemble the knife plate, both pads with glued veneer along with the pin and clamp everything in a vice until the epoxy resin has completely cured.

6. Pre-shape the handle using first a band saw, a carpet knife, then a grinder and coarse sandpaper.

7. Bring the shape and smoothness of the surface of the handle to the required level with sanding paper of decreasing grit. We finally polish the surface of the handle, wipe it with a clean rag and apply a transparent waterproof varnish. This will protect our kitchen knives from moisture.

8. The knife is completely ready for use. It turned out to be functional and beautiful.

P.S.

If the overlays are covered with veneer, then only the ends can be machined, otherwise the veneer coating can be damaged.

Original article in English

Similar master classes

How to make a durable and anatomical knife handle in 10 minutes

DIY concrete knife handle

The fastest and easiest way to make a knife handle

No worse than the factory one: Knife handle made of polypropylene pipe

How to make comfortable handles from toothbrushes using needle files

How to make a simple handle for a broken knife

Particularly interesting

Comments (16)