Homemade muffler for brush cutters

Everyone is familiar with this terrible sound of a trimmer working; it irritates not only the mower himself, but also everyone around him. It’s worth working with a lawn mower even for a short time and this ringing just stays in your ears. This drawback resulted from the use of a miniature muffler in its composition. I decided to make my own remote muffler for the trimmer in order to significantly reduce the noise level it produces.

The first thing you need to do is record the sound of the old, built-in specimen, so that you can then compare it with the new exhibit.

The level just went off scale. Incredibly loud, especially up close. The sound is sharp, high-pitched, sawing, disgustingly vile and annoying.

Will need

- Steel tube 20-25 mm in diameter.

- A piece of steel pipe 80-100 mm in diameter and 120-150 mm long.

- Glass wool.

- Steel rectangle 3-5 mm thick.

Making a muffler for a trimmer

We will make a simple straight-through muffler.

We place the pipe on a steel strip and spray it with aerosol red so that the pipe leaves an outline.

Using a grinder, cut out two round pieces.

We drill a hole in both. The diameter is the same as a thin tube.

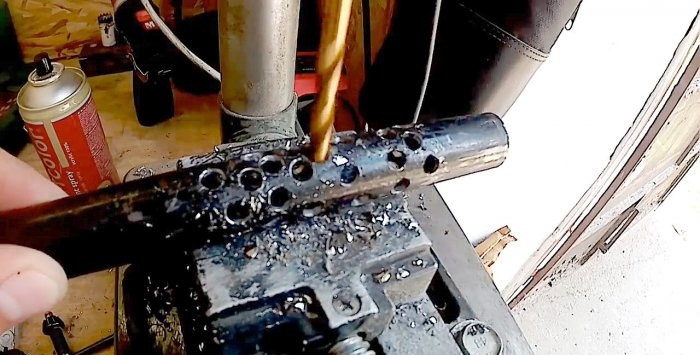

In a thin tube, we retreat approximately 50 mm from one edge and drill holes in a scattered pattern at a distance of a large cylinder.

We insert the tube into the hole of one round piece. We do welding.

We put on a large cylinder and weld it to the round.

We stuff glass wool inside. There is no need to press hard, and it should not move freely inside.

We put on the second round and scald.

We sand the entire structure.

Next, you need to connect this muffler to the engine to replace the old one.

We remove the standard muffler.

We lean it against a strip of steel to notice the working holes.

Drill one large and two small holes.

From another thin tube we make an oblique cut at a distance of 35-40 mm.

We weld at right angles.

We weld it to a rectangle with holes.

We weld our pipeline with fastening to the main muffler.

We sand everything with a sander. View of the finished muffler.

Temporarily install the muffler in place for testing. We start the trimmer and listen to it at work.

We cut grooves for the new muffler in the protective cover of the trimmer.

We install it temporarily and check that nothing interferes.

We paint and install a permanent muffler instead of the standard one.

Now the brush cutter is much quieter. The sound became lower in timbre, smoother, and, naturally, lower in level. Using the tool has become more comfortable and enjoyable.

Watch the video

Similar master classes

Particularly interesting

Comments (26)