Insulation of floors with penoplex and OSB sheets

In order to increase heat saving in the house, it is necessary to insulate it. In addition to insulating walls and windows, it is important to pay attention to the floor. Now we will look at one of the simple but effective ways to insulate the floor, using penoplex, as well as OSB sheets.

First you need to prepare the floor surface. This insulation option can be used on any floor surface, regardless of the material (wood, concrete). In the example in the illustration you can see an old surface made of wooden planks. It is not necessary to dismantle the old surface if it is not rotten and is in good condition. During preparatory work, it is necessary to dismantle the old baseboard.

If the surface is partially damaged, then only these areas can be dismantled and replaced.

Next, you need to determine from which point in the room you will begin installation. Try to use a building level or water level to identify the highest point from the edge and start from there.

Ideally, the surface should be flat, or relatively flat, without too much variation. Therefore, if in your case the concrete screed is not level, it is better to first level the surface.In our example, the wooden floors were approximately level, so we could start working right away.

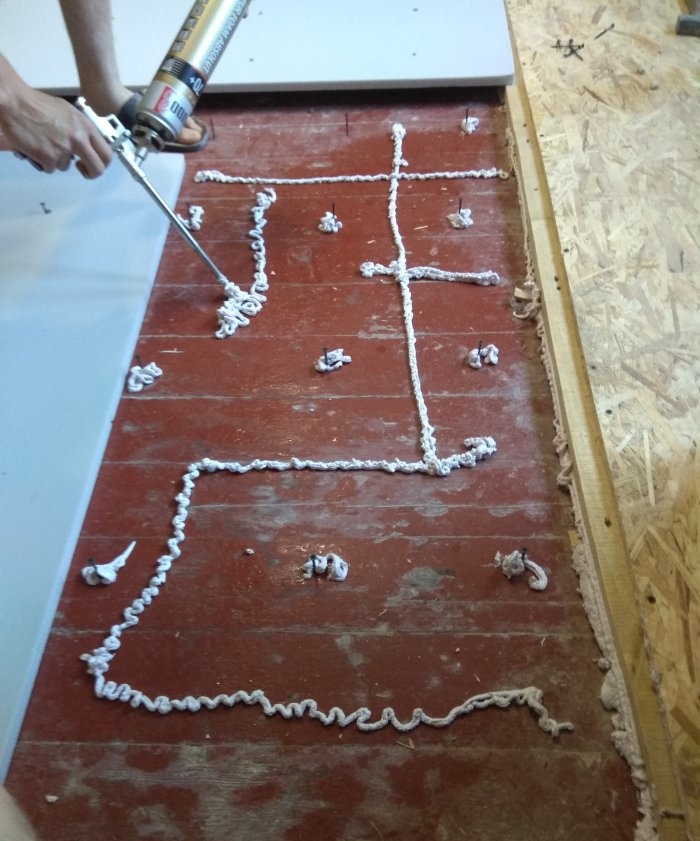

The standard size of OSB sheets is 2500x1250 mm. Therefore, it is necessary to step back from the edge of the wall by approximately 1240 mm, and screw a wooden block 20 - 25 mm thick to the floor, on which the OSB will subsequently be laid. Also, a wooden block is attached near the wall. Then, using polyurethane foam, the corners are coated, as well as the surface of the floor inside the bars where the penoplex will be laid.

It is best to use polyurethane foam with a special gun, as this is a more economical and convenient option. In this case, the foam does not dry out and can be used for several days, while conventional cylinders must be used immediately after opening. After this, penoplex is laid on the foam.

You will also need a construction knife to trim the foam. Next, you need to coat the foam again with polyurethane foam and put an OSB sheet on top. Finally, the OSB sheets are screwed with self-tapping screws to the wooden planks along the edges.

For the floor, it is necessary to use thin OSB, otherwise it will sag under heavy weight. The minimum thickness of OSB should be 16 mm.

Another installation option is applicable if the floors are not level, which is why it is not possible to fill wooden blocks, since they will also not be level. In such a situation, you can screw self-tapping screws into the wooden floor, with an indentation of 10 - 15 cm in rows. However, the screw heads must be level.To do this, place a building level on 1 row of screws and make sure that it rests on all the screws without gaps.

After all the screws are tightened, the surface is coated with polyurethane foam, on which foam sheets are laid.

After this, foam is also applied on top of the penoplex. Next, an OSB sheet is laid, which is screwed to the floor with long self-tapping screws. To trim OSB you will need a jigsaw.

For better waterproofing, fill all seams between foam sheets and OSB sheets with polyurethane foam. The same must be done along the edges, between the wall and the OSB.

This option is an excellent way to insulate floors, as well as level them. After this, you can lay laminate or linoleum on OSB.

Preparation

First you need to prepare the floor surface. This insulation option can be used on any floor surface, regardless of the material (wood, concrete). In the example in the illustration you can see an old surface made of wooden planks. It is not necessary to dismantle the old surface if it is not rotten and is in good condition. During preparatory work, it is necessary to dismantle the old baseboard.

If the surface is partially damaged, then only these areas can be dismantled and replaced.

Next, you need to determine from which point in the room you will begin installation. Try to use a building level or water level to identify the highest point from the edge and start from there.

Ideally, the surface should be flat, or relatively flat, without too much variation. Therefore, if in your case the concrete screed is not level, it is better to first level the surface.In our example, the wooden floors were approximately level, so we could start working right away.

Laying penoplex with OSB sheets

The standard size of OSB sheets is 2500x1250 mm. Therefore, it is necessary to step back from the edge of the wall by approximately 1240 mm, and screw a wooden block 20 - 25 mm thick to the floor, on which the OSB will subsequently be laid. Also, a wooden block is attached near the wall. Then, using polyurethane foam, the corners are coated, as well as the surface of the floor inside the bars where the penoplex will be laid.

It is best to use polyurethane foam with a special gun, as this is a more economical and convenient option. In this case, the foam does not dry out and can be used for several days, while conventional cylinders must be used immediately after opening. After this, penoplex is laid on the foam.

You will also need a construction knife to trim the foam. Next, you need to coat the foam again with polyurethane foam and put an OSB sheet on top. Finally, the OSB sheets are screwed with self-tapping screws to the wooden planks along the edges.

For the floor, it is necessary to use thin OSB, otherwise it will sag under heavy weight. The minimum thickness of OSB should be 16 mm.

Another option for uneven floors

Another installation option is applicable if the floors are not level, which is why it is not possible to fill wooden blocks, since they will also not be level. In such a situation, you can screw self-tapping screws into the wooden floor, with an indentation of 10 - 15 cm in rows. However, the screw heads must be level.To do this, place a building level on 1 row of screws and make sure that it rests on all the screws without gaps.

After all the screws are tightened, the surface is coated with polyurethane foam, on which foam sheets are laid.

After this, foam is also applied on top of the penoplex. Next, an OSB sheet is laid, which is screwed to the floor with long self-tapping screws. To trim OSB you will need a jigsaw.

For better waterproofing, fill all seams between foam sheets and OSB sheets with polyurethane foam. The same must be done along the edges, between the wall and the OSB.

This option is an excellent way to insulate floors, as well as level them. After this, you can lay laminate or linoleum on OSB.

Similar master classes

Particularly interesting

How to install a socket if there are short wires left

How to eliminate gaps between the chimney and slate

How to mix an ultra-reliable solution for the oven that does not give

There will be no more cracks: What to add to concrete to make it

Never buy ball valves without checking with me

New technology for floor insulation with penoplex

Comments (3)