There will be no more cracks: What to add to concrete to make it strong and durable

In order for the poured concrete to be as strong and durable as possible, it is necessary to follow the technology when concreting. Otherwise, it may crumble, crack, or simply not gain maximum strength.

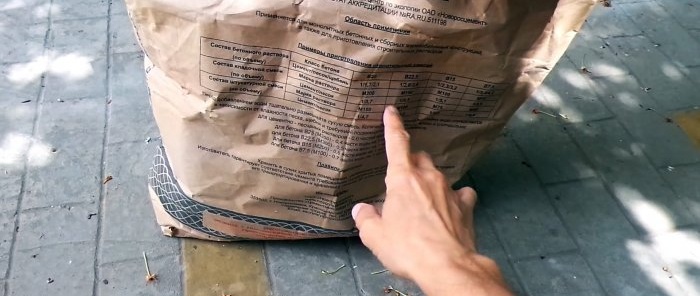

Choice of cement and proportions

The proportions when mixing concrete depend on the brand of cement used. It is optimal to use M500 cement; Portland cement is a little worse. The M500 brand is more expensive than others, but it consumes less. As a result, the cost of concrete on it will be the same as on M300 or M400, and delivery costs are relatively small.

When pouring the screed, it is optimal to use the proportions of 1 part M500 cement to 3 parts sand. For masonry mortar and plaster, the best ratio is 1:4. This ratio prevents concrete from spilling out and cracking. To reduce the cost, crushed stone can be added to the solution for a screed, foundation or reinforced belt, preferably no more than 1:1.

The less water in concrete, the stronger it will be. But if there is a lack of it, it is difficult to work with it, since it does not spread well.When there is a lot of water, concrete does not gain maximum strength. It is optimal to add it so that the consistency of the solution is convenient for work, nothing more.

Plasticizers

To increase the plasticity of concrete, plasticizers are added strictly according to the instructions. Their presence makes the solution easier to work with and reduces the amount of water poured into it. This is a very useful cheap supplement that should not be neglected. It is important not to pour more plasticizer than the recommended amount, as this will reduce the strength of the concrete.

Reinforcement and mesh

Rebar or mesh is used to reinforce concrete.

Their presence in the thickness increases fracture and tensile strength, and prevents cracking in case of uneven shrinkage. You can use steel or fiberglass reinforcement. Steel is heavier, more expensive, but also reliable. Fiberglass does not have such strong adhesion to concrete, so it works worse. You can also use any available scrap metal for reinforcement. These can be cuttings of pipes, round timber, mesh, wire.

Laying reinforcement is mandatory when pouring a foundation, interfloor slab or reinforced belt. For a regular screed it is desirable, but not necessary. For such purposes, you can use a cheaper mesh.

Fiber fiber

Fiber fiber can be used to reinforce concrete over the entire cross-section. The most reliable option is basalt fiber. It mixes easily and gives maximum strength. Polypropylene fiber can be used for plasters, as its addition reduces their slipping off the walls. It is also advisable to use it in screeds, where it supports the concrete in the first days, until it has completely set.Polypropylene fiber fiber prevents severe shrinkage, but does not work as well and for a long time as basalt fiber.

Pigment

If it is necessary to paint concrete a certain color, a pigment is used. It is poured onto the hardening screed when ironing is performed. The pigment eats deeply into the structure of concrete, due to which it is colored in thickness. As a result, the color will not be erased like a surface layer of paint.

Moisture-repellent impregnation

In order to increase the moisture-repellent qualities of concrete, impregnations are used. Their most affordable option is liquid glass. It creates a waterproof crust on the concrete surface that is resistant to wear. Thanks to impregnation, it does not crumble, does not absorb dirty stains, and is not destroyed due to water freezing in microcracks. Liquid glass treatment is carried out in 3 layers. First, it is diluted with water in a ratio of 1:1, then 1:05, and the third impregnation is performed with a pure composition.

Impregnation with epoxy resin will be more reliable and durable. However, this is too expensive and is more applicable in the manufacture of concrete countertops. For a regular screed, such processing is unnecessary.

The result of using modern technologies

Watch the video

Similar master classes

Not a crack in 30 years: A method of strengthening concrete by ironing

How to make imitation flat cobblestones from cement

You won't believe how cool things can be made from bottles and

Concrete baskets

How to make reinforced concrete pillars for garden and household needs

Do-it-yourself concrete tabletop is easy

Particularly interesting

How to install a socket if there are short wires left

How to eliminate gaps between the chimney and slate

How to mix an ultra-reliable solution for the oven that does not give

There will be no more cracks: What to add to concrete to make it

Never buy ball valves without checking with me

New technology for floor insulation with penoplex

Comments (3)