Simple DIY folding clothes dryer

This is a very convenient clothes dryer that will not disturb anyone, since it easily folds when not in use. Very simple design to repeat.

In order to extend the “life” of clothes and linen and at the same time maintain their presentation, they should not only be washed correctly, but also dried properly. It is especially useful to do this outdoors, when they are exposed to natural factors - wind and sun, and they acquire an incomparable aroma.

In the upcoming work, we can make do with the following materials:

To work we will need the most common tools and equipment:

Let's start working with the main and most loaded components of our homemade product - two cantilever-type brackets, between which a clothesline or cord will be attached, usually in several rows.

A thick-walled square-section metal pipe is suitable for them, from which we cut two pieces of the required length.

From a metal sheet with a thickness of at least 5 mm, we cut out two identical plates of the calculated size, and from a steel equal-flange angle we cut off two fragments of equal length, slightly exceeding their height.

According to the markings, we remove part of one shelf from each section of the corner.

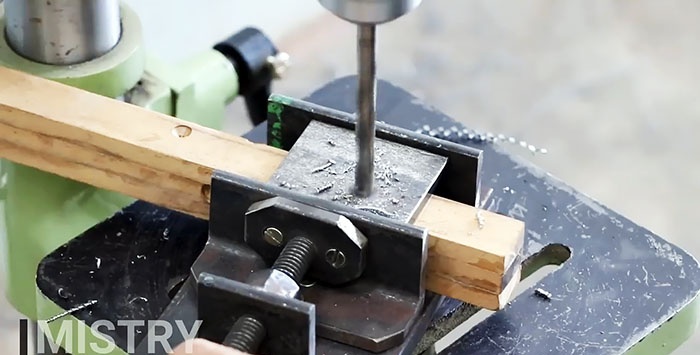

We arrange these elements in the order in which they will be located in the rotary assembly, and mark the drilling locations, slightly offset from the center, at the base of the entire shelf of corners.

We drill holes in them, and also repeat this operation for the consoles at one end with careful processing of the end part.

We also make two symmetrical holes in the shortened height shelves of the corner elements, the corners of which are rounded.

We again install the corners, tightened together with a bolt and nut, and the bracket between them, onto the plate and mark the places for drilling 4 holes in it. We carry out drilling.

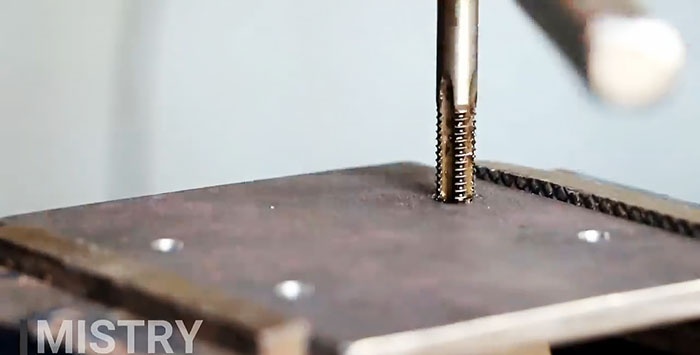

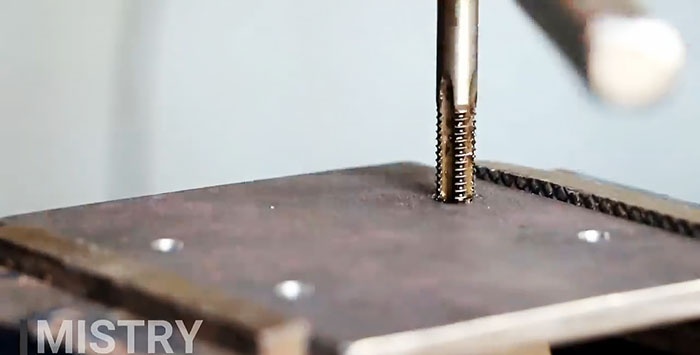

Next, we cut threads in these four holes using a hand tap with a crank.

We install the corners on the plate with a bracket between them, centered along the drillings, and mark the locations of the holes in the corners with which the plate will be attached to the wall.

We attach the corners to the plates in pairs using bolts with round hexagon heads.

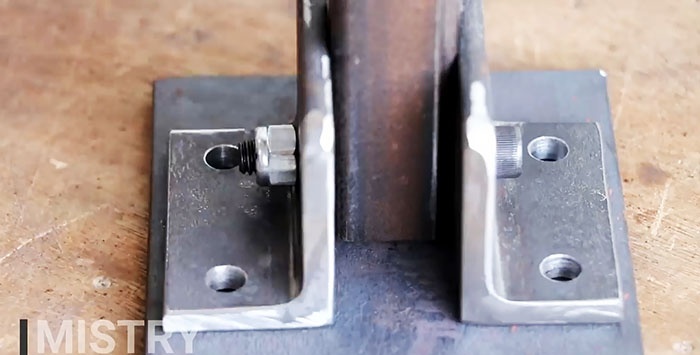

We install the bracket vertically between the corners, focusing on the corresponding holes, pass the bolt and tighten these three elements with a nut.We also tighten the bolts securing the corners to the plate using an open-end and hex wrench.

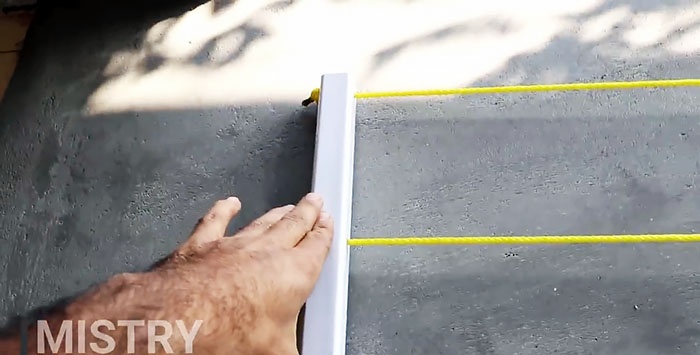

We lay the bracket with the attachment and rotation unit on its side and mark on it the places for drilling three holes at equal distances from each other, through which a clothesline or cord will be passed.

We make 6 through holes in two brackets according to the marks.

Insert the limit bolt into the holes in the corners and tighten it with a nut. It will ensure the horizontal position of the brackets under load when drying wet laundry.

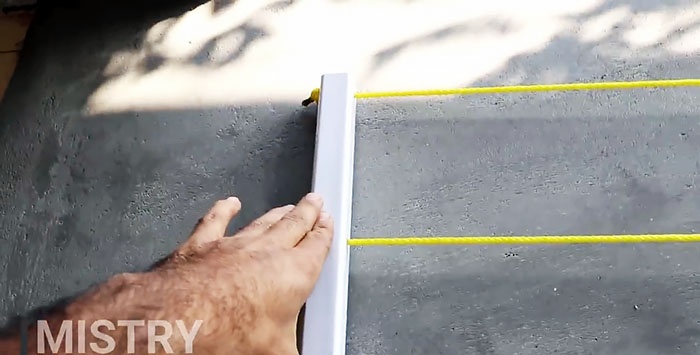

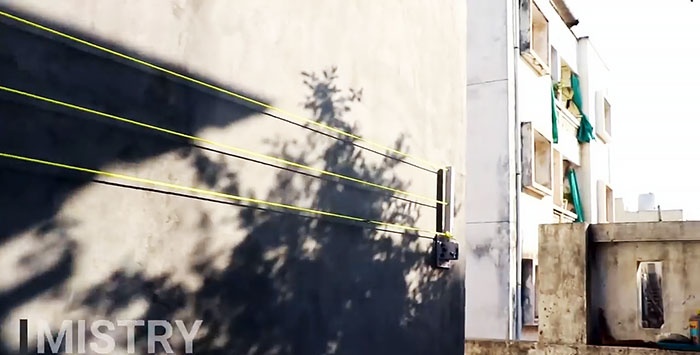

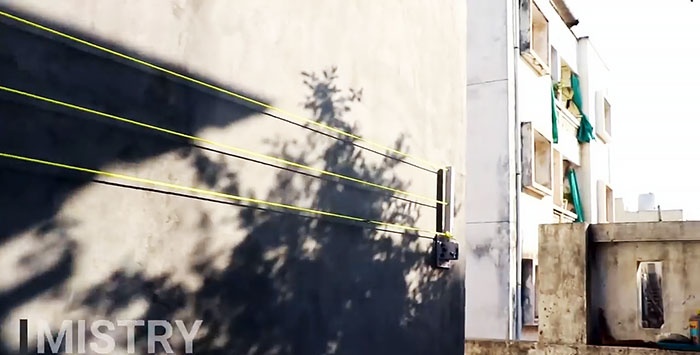

We fix the brackets on a vertical wall and stretch a clothesline or cord through the holes in them, tying the ends with a secure knot.

After drying the clothes, the brackets can be rotated around their axes and, together with the ropes, pressed against the wall so that they do not interfere with the passage or passage, and also do not get exposed to rain or snow.

In order to extend the “life” of clothes and linen and at the same time maintain their presentation, they should not only be washed correctly, but also dried properly. It is especially useful to do this outdoors, when they are exposed to natural factors - wind and sun, and they acquire an incomparable aroma.

Required

In the upcoming work, we can make do with the following materials:

- profile square pipe;

- metal sheet;

- equal-flange steel angle;

- hex head bolts, nuts;

- clothesline made of natural or artificial materials.

To work we will need the most common tools and equipment:

- pendulum saw, grinder;

- tape measure, metal ruler, marker;

- drilling machine;

- bench vice;

- core, hammer;

- tap with a knob;

- hex and open-end wrenches.

Manufacturing procedure for a folding dryer

Let's start working with the main and most loaded components of our homemade product - two cantilever-type brackets, between which a clothesline or cord will be attached, usually in several rows.

A thick-walled square-section metal pipe is suitable for them, from which we cut two pieces of the required length.

From a metal sheet with a thickness of at least 5 mm, we cut out two identical plates of the calculated size, and from a steel equal-flange angle we cut off two fragments of equal length, slightly exceeding their height.

According to the markings, we remove part of one shelf from each section of the corner.

We arrange these elements in the order in which they will be located in the rotary assembly, and mark the drilling locations, slightly offset from the center, at the base of the entire shelf of corners.

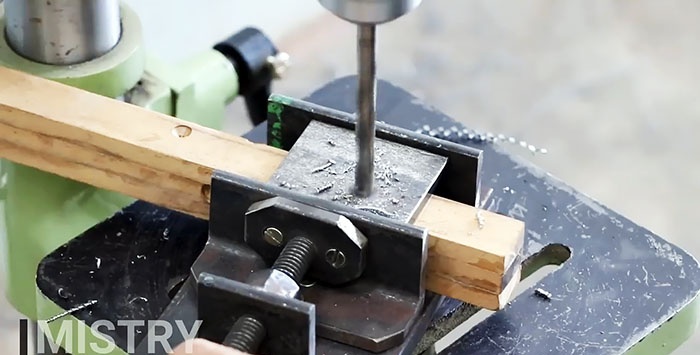

We drill holes in them, and also repeat this operation for the consoles at one end with careful processing of the end part.

We also make two symmetrical holes in the shortened height shelves of the corner elements, the corners of which are rounded.

We again install the corners, tightened together with a bolt and nut, and the bracket between them, onto the plate and mark the places for drilling 4 holes in it. We carry out drilling.

Next, we cut threads in these four holes using a hand tap with a crank.

We install the corners on the plate with a bracket between them, centered along the drillings, and mark the locations of the holes in the corners with which the plate will be attached to the wall.

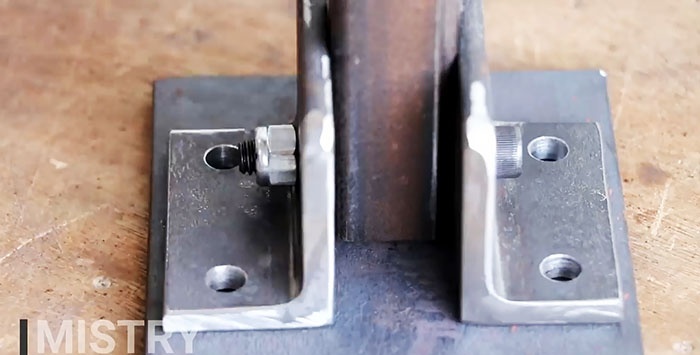

We attach the corners to the plates in pairs using bolts with round hexagon heads.

We install the bracket vertically between the corners, focusing on the corresponding holes, pass the bolt and tighten these three elements with a nut.We also tighten the bolts securing the corners to the plate using an open-end and hex wrench.

We lay the bracket with the attachment and rotation unit on its side and mark on it the places for drilling three holes at equal distances from each other, through which a clothesline or cord will be passed.

We make 6 through holes in two brackets according to the marks.

Insert the limit bolt into the holes in the corners and tighten it with a nut. It will ensure the horizontal position of the brackets under load when drying wet laundry.

We fix the brackets on a vertical wall and stretch a clothesline or cord through the holes in them, tying the ends with a secure knot.

After drying the clothes, the brackets can be rotated around their axes and, together with the ropes, pressed against the wall so that they do not interfere with the passage or passage, and also do not get exposed to rain or snow.

Watch the video

Similar master classes

Particularly interesting

Comments (1)