Making wine at home

This year we had a big grape harvest. For us, this is the Kaluga region, Borovsky district, i.e. the very middle zone of Russia, a zone of risky farming. The weather contributed to this to a large extent, although it varied throughout the summer, but at key moments it was very favorable for the grapes: the first period was the flowering of the grapes and the formation of ovaries; from mid-May to mid-June there was very warm, dry weather, daytime the temperature remained steadily around 25-30 degrees Celsius.

Then, the middle of summer turned out to be cold and rainy, and it seemed that a serious threat hung over the harvest: the grapes did not grow, did not turn red, it was clear that they were not feeling well in such conditions. But August corrected everything, the temperature again stayed at 25 degrees Celsius and above, the grapes came to life, began to grow, quickly turned red, gained sugar content, and by the beginning of September they were almost ready for harvesting and processing.

The grapes from which we will make wine are called “Isabella”, it is red, with seeds inside.This variety is unpretentious during cultivation, does not require shelter for the winter, and is resistant to various types of grape infections and diseases, such as the mildew fungus. The taste is average, and of course cannot be compared with store-bought or southern Crimean varieties, but if it has time to ripen, like this year, it is still very tasty. This year I literally ate too much of it, I never remember this before, and I’ve been growing grapes for six years now. There were so many grapes this year that you couldn’t eat them all, so they had to be collected, processed and made into wine.

Lyrical digression: I dried about a bucket of grapes in an electric dryer for dried fruits, thereby providing myself with a delicious compote for the long winter. These grapes are not suitable for making jam or raisins due to the large number of seeds.

To prepare homemade wine, we need at least two plastic barrels with a capacity of 30 to 50 liters. The number of barrels depends on the grapes collected, in my case four barrels were enough, but one barrel should be empty, since during the wine making process you will need to transfer the wine must from one barrel to another once. So, we put the collected grapes in a barrel to the top, take a berry crusher, in my case it is a wooden mallet about a meter long, and crush the berries in the same way as we prepare mashed potatoes, until they are all immersed in grape juice.

The berries will shrink to about half, after this you need to add grapes to the barrel, mash them again, leaving about fifteen centimeters to the top of the barrel, since when the fermentation process begins, the berry pulp will begin to rise, and if you leave a small distance, the valuable product will begin to pour out of barrels directly on the floor. It's a pity!

We close the barrels with lids, which are sold complete with the barrels. We place the barrels with crushed berries in a cool basement. The recommended temperature for fermenting wine should be between 16 and 22 degrees Celsius. On the second or third day, the fermentation process will begin; it will be visible visually in the form of red foam on the surface of the crushed berries.

Also, if you open the barrel, you will smell the fermentation, the first notes of your young wine and carbon dioxide, which seems to be odorless, but it hits your nose, just hold on.

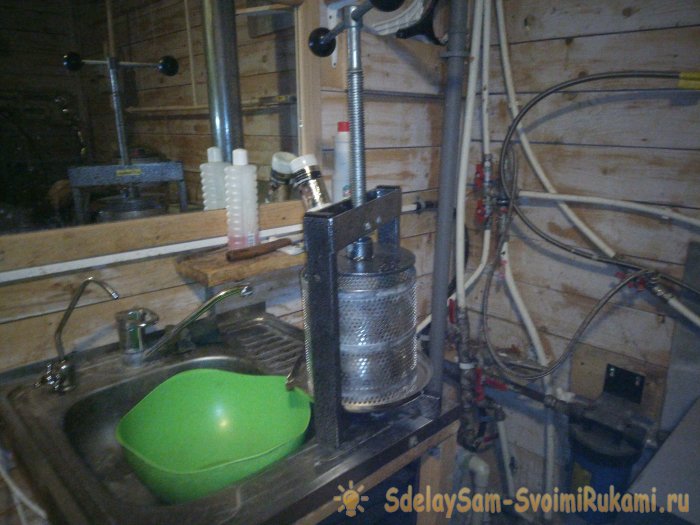

Next, we leave the barrel (or several barrels) alone for two weeks. During this time, the berries will ferment, soften, flow, and begin to release juice easily. At the appointed time, we go down to the basement, take out a press for squeezing juice, and install it approximately as in the photo.

At the beginning of my winemaking activity, I did without such a press, using a gauze-rag squeezer: we put grape cake in the center of the rag, twist it, knead it, press it, squeezing out pure juice, all the seeds, twigs and other waste remain inside. The process is difficult and long, so I bought myself a special small press, which I advise you to do.

By twisting the press lever clockwise, pure juice is released from the berry mixture, while the dry pulp remains inside the mesh. Now we need a clean barrel, which I mentioned earlier.

We pour the pure juice, which from now on we will not call wine, but already wine must, into a clean empty barrel. We put the waste in a bucket, then throw it into the compost heap. After processing one thirty-five-liter barrel, approximately one bucket of waste (ten liters) and 20-25 liters of wine must were obtained.

It is advisable, but in my experience not necessary, to add another ten liters of wort into this barrel, since this air-oxygen cushion harms the taste of the wine, and the presence of oxygen can provoke the formation of vinegar from the wine. At this stage, you can add sugar to the prepared must according to your taste, because in our region the grapes are still not sweet enough to achieve a certain wine strength or a sweet-semi-sweet taste. But it depends on your taste preferences, if you like a weak degree and sour taste, such as “brut”, then you don’t need to add sugar. After adding sugar, the fermentation process will begin with renewed vigor.

We leave the wine must to ferment in the cellar for another two to three months, in December the wine should be ready, pour it into bottles, jars, seal it tightly, open wine can spoil, closed wine can be stored for years, gaining flavor from year to year. Sweet and semi-sweet wines are stored longer and better than dry ones, sugar is an additional preservative, and sweet wines are usually 1-3 degrees stronger in alcohol content, which is also not unimportant.

I would like to say a few more words about the water castle.

In this case, a hole is made in the lid of the barrel, a plastic tube is tightly inserted into it, which in turn is inserted into a jar of water. Fermentation gases leave the barrel through this tube, and air from outside does not enter the barrel, since water from the jar does not allow air into the tube.Often at home, people make similar air locks from rubber or latex gloves; the operating principle is the same; excess pressure can escape from the inside, but nothing will get inside. This is necessary so that the wine does not turn into vinegar; if there are temperatures above 20 degrees Celsius, and there is free access to oxygen, then the vinegar bacteria will defeat the wine bacteria, and your wort will disappear, or you will have a whole barrel of grape vinegar. Sometimes I make a lock, sometimes I don’t, but the barrel must be closed with a lid, not very tightly, so that excess gases can escape from inside.

That seems to be all. Have a nice New Year with your own homemade young wine!

Then, the middle of summer turned out to be cold and rainy, and it seemed that a serious threat hung over the harvest: the grapes did not grow, did not turn red, it was clear that they were not feeling well in such conditions. But August corrected everything, the temperature again stayed at 25 degrees Celsius and above, the grapes came to life, began to grow, quickly turned red, gained sugar content, and by the beginning of September they were almost ready for harvesting and processing.

Grapes for wine

The grapes from which we will make wine are called “Isabella”, it is red, with seeds inside.This variety is unpretentious during cultivation, does not require shelter for the winter, and is resistant to various types of grape infections and diseases, such as the mildew fungus. The taste is average, and of course cannot be compared with store-bought or southern Crimean varieties, but if it has time to ripen, like this year, it is still very tasty. This year I literally ate too much of it, I never remember this before, and I’ve been growing grapes for six years now. There were so many grapes this year that you couldn’t eat them all, so they had to be collected, processed and made into wine.

Lyrical digression: I dried about a bucket of grapes in an electric dryer for dried fruits, thereby providing myself with a delicious compote for the long winter. These grapes are not suitable for making jam or raisins due to the large number of seeds.

Making homemade wine

To prepare homemade wine, we need at least two plastic barrels with a capacity of 30 to 50 liters. The number of barrels depends on the grapes collected, in my case four barrels were enough, but one barrel should be empty, since during the wine making process you will need to transfer the wine must from one barrel to another once. So, we put the collected grapes in a barrel to the top, take a berry crusher, in my case it is a wooden mallet about a meter long, and crush the berries in the same way as we prepare mashed potatoes, until they are all immersed in grape juice.

The berries will shrink to about half, after this you need to add grapes to the barrel, mash them again, leaving about fifteen centimeters to the top of the barrel, since when the fermentation process begins, the berry pulp will begin to rise, and if you leave a small distance, the valuable product will begin to pour out of barrels directly on the floor. It's a pity!

We close the barrels with lids, which are sold complete with the barrels. We place the barrels with crushed berries in a cool basement. The recommended temperature for fermenting wine should be between 16 and 22 degrees Celsius. On the second or third day, the fermentation process will begin; it will be visible visually in the form of red foam on the surface of the crushed berries.

Also, if you open the barrel, you will smell the fermentation, the first notes of your young wine and carbon dioxide, which seems to be odorless, but it hits your nose, just hold on.

Next, we leave the barrel (or several barrels) alone for two weeks. During this time, the berries will ferment, soften, flow, and begin to release juice easily. At the appointed time, we go down to the basement, take out a press for squeezing juice, and install it approximately as in the photo.

At the beginning of my winemaking activity, I did without such a press, using a gauze-rag squeezer: we put grape cake in the center of the rag, twist it, knead it, press it, squeezing out pure juice, all the seeds, twigs and other waste remain inside. The process is difficult and long, so I bought myself a special small press, which I advise you to do.

By twisting the press lever clockwise, pure juice is released from the berry mixture, while the dry pulp remains inside the mesh. Now we need a clean barrel, which I mentioned earlier.

We pour the pure juice, which from now on we will not call wine, but already wine must, into a clean empty barrel. We put the waste in a bucket, then throw it into the compost heap. After processing one thirty-five-liter barrel, approximately one bucket of waste (ten liters) and 20-25 liters of wine must were obtained.

It is advisable, but in my experience not necessary, to add another ten liters of wort into this barrel, since this air-oxygen cushion harms the taste of the wine, and the presence of oxygen can provoke the formation of vinegar from the wine. At this stage, you can add sugar to the prepared must according to your taste, because in our region the grapes are still not sweet enough to achieve a certain wine strength or a sweet-semi-sweet taste. But it depends on your taste preferences, if you like a weak degree and sour taste, such as “brut”, then you don’t need to add sugar. After adding sugar, the fermentation process will begin with renewed vigor.

We leave the wine must to ferment in the cellar for another two to three months, in December the wine should be ready, pour it into bottles, jars, seal it tightly, open wine can spoil, closed wine can be stored for years, gaining flavor from year to year. Sweet and semi-sweet wines are stored longer and better than dry ones, sugar is an additional preservative, and sweet wines are usually 1-3 degrees stronger in alcohol content, which is also not unimportant.

I would like to say a few more words about the water castle.

In this case, a hole is made in the lid of the barrel, a plastic tube is tightly inserted into it, which in turn is inserted into a jar of water. Fermentation gases leave the barrel through this tube, and air from outside does not enter the barrel, since water from the jar does not allow air into the tube.Often at home, people make similar air locks from rubber or latex gloves; the operating principle is the same; excess pressure can escape from the inside, but nothing will get inside. This is necessary so that the wine does not turn into vinegar; if there are temperatures above 20 degrees Celsius, and there is free access to oxygen, then the vinegar bacteria will defeat the wine bacteria, and your wort will disappear, or you will have a whole barrel of grape vinegar. Sometimes I make a lock, sometimes I don’t, but the barrel must be closed with a lid, not very tightly, so that excess gases can escape from inside.

That seems to be all. Have a nice New Year with your own homemade young wine!

Similar master classes

Particularly interesting

Comments (7)