How to easily hide a self-tapping screw in wood

In the process of connecting wooden parts with screws, screws or self-tapping screws, sometimes it becomes necessary to install them inconspicuously, either for decorative purposes, or for safety and ease of use in the future. Below we will look at a simple and effective way to do this quickly and without much effort.

To realize our plans, we should prepare the following simple materials and ordinary tools:

Lightly moisten the surface of a wooden block or board with water so that the wood fibers soften a little under the influence of moisture and become less brittle.

We place the chisel blade in the area where the hardware is screwed in at an optimal angle and with gentle blows of the mallet on the handle of the tool, we separate a strip of wood 5-6 cm long.

Thanks to the applied liquid, the bent fragment and nearby layers of wood are softened, which reduces to zero the possibility of its mechanical separation from the rest of the block or board.

Under the bent strip, using a drill and a drill bit, we make a hole for the fastener. We drill out its entrance with a countersink so that the head of the hardware is completely recessed in the wood after screwing it in and final tightening.

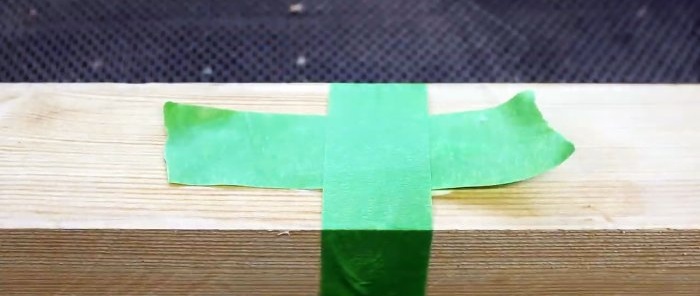

With some reserve, lubricate the bent strip and the recess in the wood with glue, press them together and apply adhesive tape, tape or a piece of plastic film on top.

We place a clamping bar on top of everything, tighten it with a clamp or clamp it in a vice. You can simply place a heavy weight on the area to be glued.

After an hour and a half, without waiting for the glue to dry completely, remove the compressive force, remove the tape and process the glued area with a sanding head and fine-grained sandpaper.

In this case, part of the fine wood dust fills the recesses and is fixed there with glue that has not yet completely dried. This further masks the place of the self-tapping screw or screw screwed into the wood.

But such a connection will have to be classified as permanent, since disassembling it will require damaging the installation site of the threaded fastener.

Will need

To realize our plans, we should prepare the following simple materials and ordinary tools:

- pieces of wooden blocks or boards;

- chisel or chisel;

- a mallet with a wooden or rubber head;

- drill, drill and countersink for wood;

- bit, self-tapping screws, screws or screws;

- PVA or wood glue;

- adhesive tape, tape or plastic film;

- vice or clamp;

- sanding head and sandpaper.

Sequence of actions for hiding fasteners

Lightly moisten the surface of a wooden block or board with water so that the wood fibers soften a little under the influence of moisture and become less brittle.

We place the chisel blade in the area where the hardware is screwed in at an optimal angle and with gentle blows of the mallet on the handle of the tool, we separate a strip of wood 5-6 cm long.

Thanks to the applied liquid, the bent fragment and nearby layers of wood are softened, which reduces to zero the possibility of its mechanical separation from the rest of the block or board.

Under the bent strip, using a drill and a drill bit, we make a hole for the fastener. We drill out its entrance with a countersink so that the head of the hardware is completely recessed in the wood after screwing it in and final tightening.

With some reserve, lubricate the bent strip and the recess in the wood with glue, press them together and apply adhesive tape, tape or a piece of plastic film on top.

We place a clamping bar on top of everything, tighten it with a clamp or clamp it in a vice. You can simply place a heavy weight on the area to be glued.

After an hour and a half, without waiting for the glue to dry completely, remove the compressive force, remove the tape and process the glued area with a sanding head and fine-grained sandpaper.

In this case, part of the fine wood dust fills the recesses and is fixed there with glue that has not yet completely dried. This further masks the place of the self-tapping screw or screw screwed into the wood.

But such a connection will have to be classified as permanent, since disassembling it will require damaging the installation site of the threaded fastener.

Watch the video

Similar master classes

Particularly interesting

Comments (0)