A reliable method for triple corner jointing of wooden parts

During production furnitureFor example, for a dining table, you need to choose the method of connecting the drawer (plank frame) with the legs. Let's consider one of the simple but reliable options on how to do this, without using additional fastening (screws, wedges, glue, etc.).

To show it, we only need a wooden beam. To prepare workpieces and process them, you will have to work with the following tools and devices:

We cut two long slats from the timber. We make the legs short for ease of work. Let's assume that we have to make a coffee table.

Due to the fact that the blade overhang above the table of the circular saw is small, this is not enough to process the end of the leg in one pass. So we rotate it 180 degrees to process the other side.

Next we will work with two legs and two slats, which are enough to show the triple corner joint method.

We press the legs one by one against the stop, and put a rail on top. Use a pencil to mark the legs on one side, then turn them 90 degrees and draw a second line.

Now we install the legs vertically one by one, and apply transverse marks to the profile of the slats.

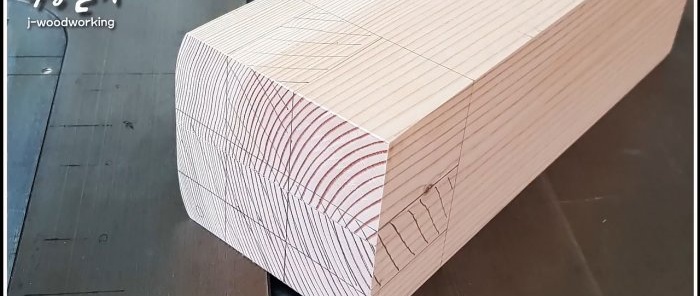

As a result, we should get the following markup grid.

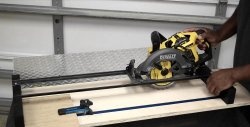

Instead of a regular saw blade removed from a circular saw, we install a dado-groove adjustable disk and set it in height exactly equal to the width of the rail.

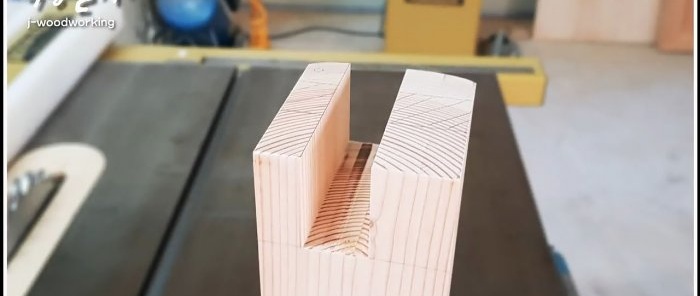

We make an even cut in the leg in two passes. At the same time, we minimize the feed, since dado discs cut slowly due to the increased cutting width. Having made the first groove, we check how tightly the rail fits.

We turn the workpiece a quarter of a circle and proceed to make the second cut. We repeat the same operations with the second leg.

We insert slats into the grooves of the legs, and mark them with a pencil to mark the vertical grooves of the legs on both sides.

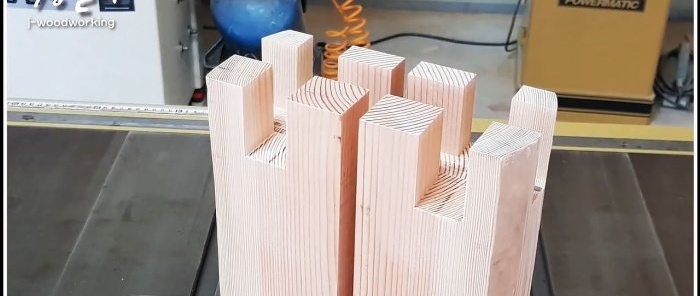

We set the disk to 50 percent of the width of the slats, and make the first pass in both slats. For precision processing, we use a template, turn the workpieces over and make a second pass.

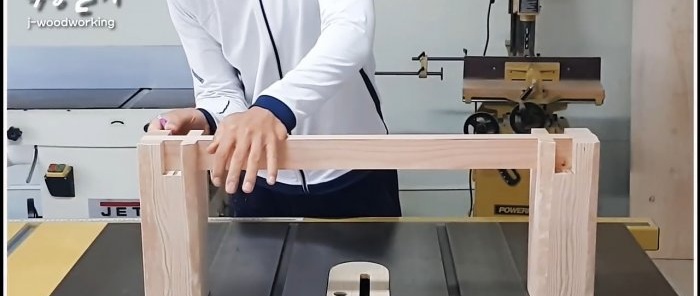

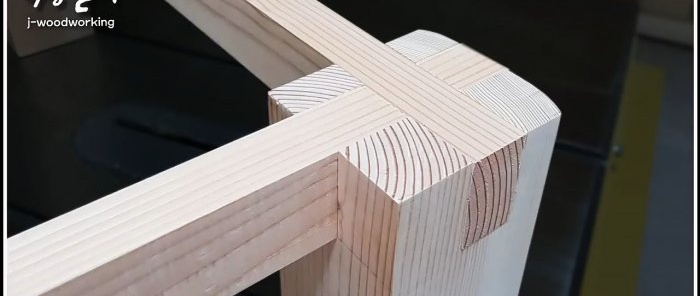

We rotate one rail 180 degrees relative to the longitudinal axis and connect it to the other. Planting density is good. After this, we assemble all the elements of the corner joint in the required order, and make sure that it turns out to be accurate, durable and aesthetic.

Will need

To show it, we only need a wooden beam. To prepare workpieces and process them, you will have to work with the following tools and devices:

- circular saw;

- saw dado-groove adjustable discs;

- clamp;

- pencil;

- template.

Manufacturing Process of Triple Corner Joint

We cut two long slats from the timber. We make the legs short for ease of work. Let's assume that we have to make a coffee table.

Due to the fact that the blade overhang above the table of the circular saw is small, this is not enough to process the end of the leg in one pass. So we rotate it 180 degrees to process the other side.

Next we will work with two legs and two slats, which are enough to show the triple corner joint method.

We press the legs one by one against the stop, and put a rail on top. Use a pencil to mark the legs on one side, then turn them 90 degrees and draw a second line.

Now we install the legs vertically one by one, and apply transverse marks to the profile of the slats.

As a result, we should get the following markup grid.

Instead of a regular saw blade removed from a circular saw, we install a dado-groove adjustable disk and set it in height exactly equal to the width of the rail.

We make an even cut in the leg in two passes. At the same time, we minimize the feed, since dado discs cut slowly due to the increased cutting width. Having made the first groove, we check how tightly the rail fits.

We turn the workpiece a quarter of a circle and proceed to make the second cut. We repeat the same operations with the second leg.

We insert slats into the grooves of the legs, and mark them with a pencil to mark the vertical grooves of the legs on both sides.

We set the disk to 50 percent of the width of the slats, and make the first pass in both slats. For precision processing, we use a template, turn the workpieces over and make a second pass.

We rotate one rail 180 degrees relative to the longitudinal axis and connect it to the other. Planting density is good. After this, we assemble all the elements of the corner joint in the required order, and make sure that it turns out to be accurate, durable and aesthetic.

Watch the video

Similar master classes

Particularly interesting

Comments (0)