Speaker Dent Remover

Any straightener knows how important a professional tool is for pulling out dents on car bodies, and how much it costs. However, it can be completely replaced with a homemade one made from an old speaker. The principle of operation is the same, but the savings are obvious. This version of the mini-lifter is capable of pulling out dents of about 1 cm. And now we will tell you how to make it.

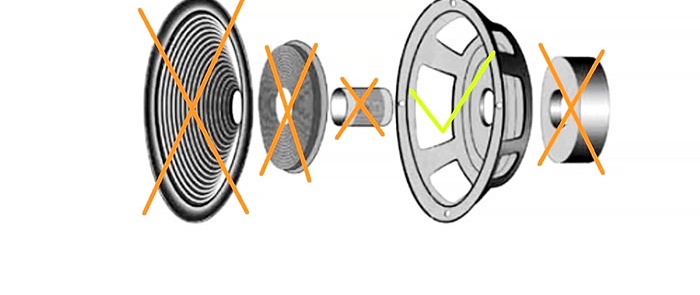

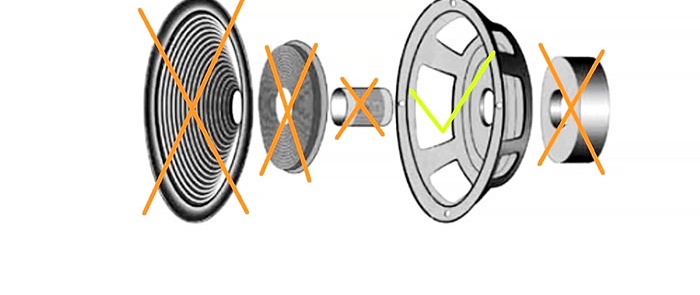

First, let's disassemble the speaker. We only need its basket (frame) with a wide washer riveted to it, which everyone usually throws away as unnecessary.

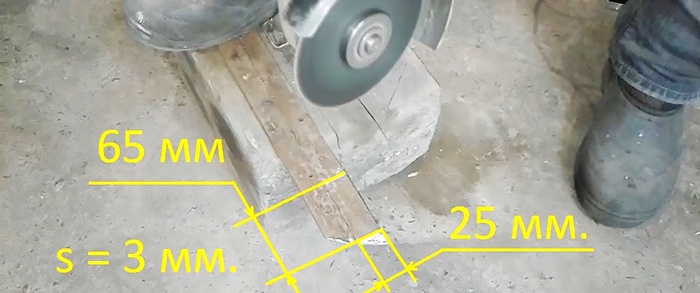

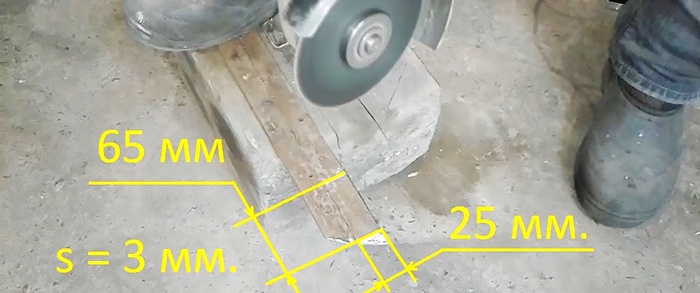

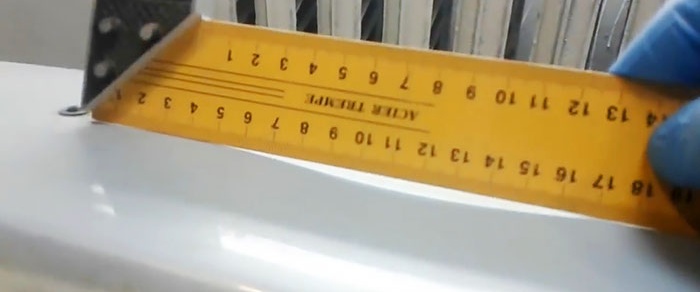

We use a grinder to cut out a metal strip of steel 3 mm thick. Dimensions: length – 65mm, width – 25mm. We weld it perpendicular to the washer.

We cut off a piece of reinforcement or metal rod 10-12 mm thick and about 20 cm long. This will be the handle for our device. We weld it to the outer end of the plate.

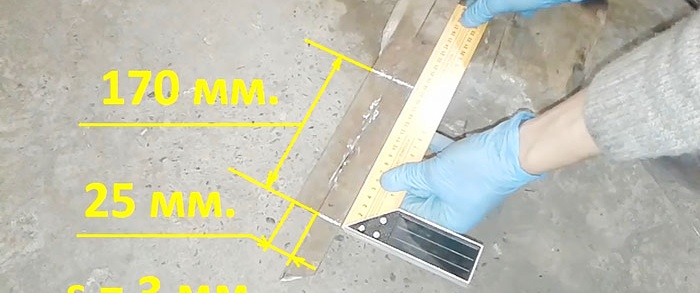

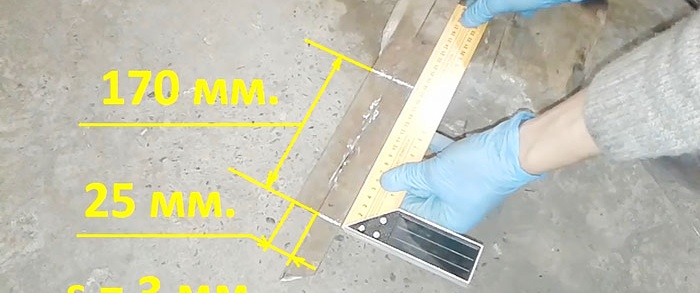

The next two metal strips from the same sheet steel will be used as the trigger lever. Dimensions: length – 170 mm, width – 25 mm.

The trigger pin will be located just below the handle and a small rivet or screw will work for it. We make a hole for it in the stand plate and the trigger assembly. We expand the hole on it to a small track, about 2 cm long. We also make a hole in the rack for the axle.

We close the edges of the trigger plates with welded stops to fix it on the axis. We carefully clean everything with a grinder.

We make the rod for pulling out dents from a tube suitable for the diameter of the washer. We flatten it to secure it to the trigger. We select the length of the tube experimentally, calculating it for the maximum pull of the trigger.

We drill a hole in the rod and trigger to connect them and ensure free movement of the lever.

Now it is necessary to provide a quick-release mechanism for coupling the rod with its end part - the fungus. To do this, we weld a washer onto the end of the rod, and then use a grinder to make an open slot at its end so that a grip is obtained.

You can also buy a factory-made mushroom made of plastic. Or you can make it yourself from a metal rod of suitable thickness. Height – about 20-25 mm. In the upper part it is necessary to make a groove with a grinder to grip the rod.

We glue a cap from a regular plastic bottle onto the base of the fungus so that there are no marks left on the metal. But the circumference of the basket in contact with the metal must be covered with a shock absorber. If the standard gasket that is glued to such speakers is not preserved, then a rubber door seal will do.

The tool is ready for use. Now you can try to test it on dents left in the metal.

You will need a hot glue gun and a degreaser (nitro thinner or alcohol). Residues of hot-melt adhesive are most carefully removed after wetting them with alcohol.

Before the pulling procedure, craftsmen advise slightly heating the metal with an electric hair dryer to make the transitions smoother.

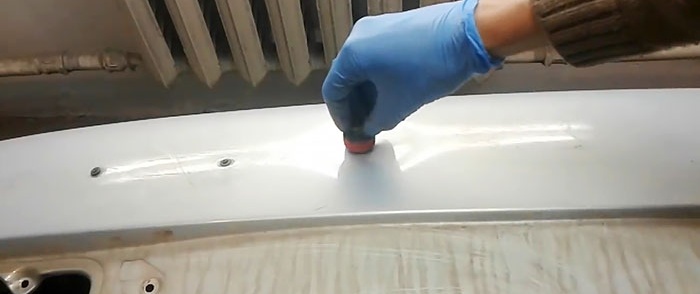

We degrease the metal surface and glue the fungus to the maximum point of the dent.

Then we place our device in the center. After waiting for the hot-melt glue to dry (about 30 seconds), we pull the rod out with a lever until the fungus is completely separated from the metal. Sometimes it is necessary to make several such manipulations in order to reduce differences on the surface of the car body to a minimum.

Try making yourself such a useful tool. Perhaps this will save you from additional expenses in auto repair shops, where they can charge a lot of money for such work.

Making a device for fixing dents

First, let's disassemble the speaker. We only need its basket (frame) with a wide washer riveted to it, which everyone usually throws away as unnecessary.

We use a grinder to cut out a metal strip of steel 3 mm thick. Dimensions: length – 65mm, width – 25mm. We weld it perpendicular to the washer.

We cut off a piece of reinforcement or metal rod 10-12 mm thick and about 20 cm long. This will be the handle for our device. We weld it to the outer end of the plate.

The next two metal strips from the same sheet steel will be used as the trigger lever. Dimensions: length – 170 mm, width – 25 mm.

The trigger pin will be located just below the handle and a small rivet or screw will work for it. We make a hole for it in the stand plate and the trigger assembly. We expand the hole on it to a small track, about 2 cm long. We also make a hole in the rack for the axle.

We close the edges of the trigger plates with welded stops to fix it on the axis. We carefully clean everything with a grinder.

We make the rod for pulling out dents from a tube suitable for the diameter of the washer. We flatten it to secure it to the trigger. We select the length of the tube experimentally, calculating it for the maximum pull of the trigger.

We drill a hole in the rod and trigger to connect them and ensure free movement of the lever.

Now it is necessary to provide a quick-release mechanism for coupling the rod with its end part - the fungus. To do this, we weld a washer onto the end of the rod, and then use a grinder to make an open slot at its end so that a grip is obtained.

You can also buy a factory-made mushroom made of plastic. Or you can make it yourself from a metal rod of suitable thickness. Height – about 20-25 mm. In the upper part it is necessary to make a groove with a grinder to grip the rod.

We glue a cap from a regular plastic bottle onto the base of the fungus so that there are no marks left on the metal. But the circumference of the basket in contact with the metal must be covered with a shock absorber. If the standard gasket that is glued to such speakers is not preserved, then a rubber door seal will do.

The tool is ready for use. Now you can try to test it on dents left in the metal.

Straightening out dents

You will need a hot glue gun and a degreaser (nitro thinner or alcohol). Residues of hot-melt adhesive are most carefully removed after wetting them with alcohol.

Before the pulling procedure, craftsmen advise slightly heating the metal with an electric hair dryer to make the transitions smoother.

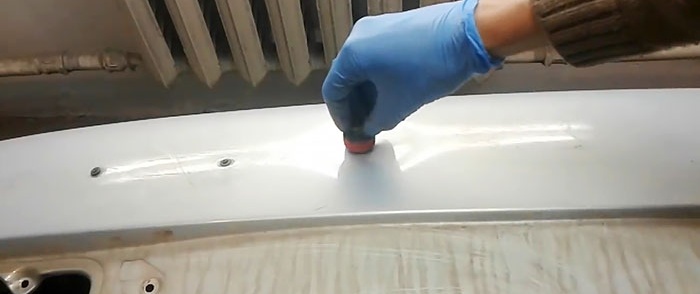

We degrease the metal surface and glue the fungus to the maximum point of the dent.

Then we place our device in the center. After waiting for the hot-melt glue to dry (about 30 seconds), we pull the rod out with a lever until the fungus is completely separated from the metal. Sometimes it is necessary to make several such manipulations in order to reduce differences on the surface of the car body to a minimum.

Try making yourself such a useful tool. Perhaps this will save you from additional expenses in auto repair shops, where they can charge a lot of money for such work.

Watch the video

Similar master classes

Particularly interesting

Comments (0)