Removable device for cutting circles in sheet metal using a grinder

You can cut a circle in sheet metal using metal scissors, making precise cutting, and having extraordinary skills. You cannot do without additional processing of the edges. You can also use a hand tool – an HC2 EV Malco drill attachment that costs about 10 thousand rubles.

Let's try to adapt an angle grinder for this purpose, equipping it with removable equipment based on a ring permanent magnet from an audio speaker. For this we will also need something else.

You will also need the following tools:

We take out the old speaker from storage, shake off the dust and clean it with a wire brush.

We clamp it by the flanges and the magnet in a vice and drill out the heads of the screws that secure the basket to the top flange. We separate the basket with the upper flange from the permanent ring magnet and the lower flange with the steel cylinder (core). We again clamp the basket with the upper flange in a vice and, using a hammer and a tool, knock the flange out of the basket.

We don’t need a basket, but a permanent ring magnet, an upper flange and a lower one with a core will be useful for making a homemade product.

We clamp the lower flange in a vice and use a grinder to cut off the core at the very base.

Next, we turn the part over, punch it in the center and drill a hole, lubricating and cooling the working area, respectively, with oil and water. We cover the surface of the lower flange from the side of the rest of the core and the ring magnet with glue and place the flange with the tip down on the magnet and, after centering, fix them.

From a steel equal angle angle of suitable size, we cut two fragments about 35 mm long.

We connect them with shelves and clamp them in this position in a vice, and weld the joint inside and out.

We sand the top seam with a grinder. We weld an elongated hex nut vertically in the center of the joint of the corners, screwing a bolt into it from above to secure the nut when welding it.

We sand the seam using a grinder. We unscrew the auxiliary bolt from the nut welded to the corners.

We clamp the structure of two corners and a nut in a vice and drill holes opposite each other on the shelves below, closer to the side, cooling the drilling site with water.

We prepare a metal strip with a characteristic bend that separates the ends of the strip along two vertical planes.

We place it on top and longitudinally to the welding seam of the corners without resting on the elongated nut and weld the handle strip in this position.

We return to the ring magnet with a flange and a nut glued from below to the core extension. We screw in a bolt with a washer and a nut from the front side of the flange.

We place an elongated hex nut on top of the bolt head and weld it in this position.

We weld the same nut, but with a smaller diameter, to the stud screwed into the elongated nut on the head of the bolt.

Assemblies consisting of two welded corners, an extended nut and a shaped handle, as well as a permanent magnet, a flange, a bolt with a nut and a washer, and an extended nut welded to the bolt head are painted with black spray paint from a can.

We place the first knot on the grinder so that the holes in the flanges of the corners coincide with the holes on the angle grinder, and the handle of the knot is directed along the body of the tool from above.

We fix the assembly on the angle grinder with bolts on both sides, and fasten the handle to the body with a clamp. Tighten all fasteners with a Phillips and flathead screwdriver.

We screw a pin into the elongated nut of the permanent magnet unit, at the end of which a nut of smaller diameter is welded.

Then we screw the pin into the nut until it appears on the other side. Continuing to rotate further, we screw the free end of the stud into the extended nut of the second assembly.

We screw a threaded handle into the nut at the end of the rod. This operation essentially completed the manufacture and installation of a homemade product on an angle grinder.

By rotating the assembly with a permanent magnet around the stud, you can increase or decrease the distance between the center of the nut (axis of rotation) and the grinder disk.

It will be equal to the radius of the circle that we are going to cut out in sheet metal, if the assembly with the magnet is installed in the center of the circle being cut out, and the grinder with the disk is moved by the handle along a given radius, pressing the tool against the metal.

After the circle is cut, turn off the grinder and lift the circle together with the angle grinder by holding it with the force of a permanent magnet of a homemade device.

The device can be detached from the angle grinder at any time and stored in a drawer until the next need.

If, by the way, your disk is tightly jammed, then there is a very simple way to unscrew the angle grinder nut - https://home.washerhouse.com/en/4301-legkiy-sposob-otkrutit-gayku-bolgarki.html

Let's try to adapt an angle grinder for this purpose, equipping it with removable equipment based on a ring permanent magnet from an audio speaker. For this we will also need something else.

You will need:

- equal-flange steel angle;

- regular and extended nuts, bolts and washers;

- hairpin with thread along the entire length;

- strip of metal;

- screws, clamp;

- black aerosol paint in a can;

- glue;

- threaded handle.

You will also need the following tools:

- drill and bit;

- bench vice;

- grinder with cutting disc;

- pliers, hammer and core;

- welding equipment;

- Phillips and flathead screwdrivers.

Manufacturing process

We take out the old speaker from storage, shake off the dust and clean it with a wire brush.

We clamp it by the flanges and the magnet in a vice and drill out the heads of the screws that secure the basket to the top flange. We separate the basket with the upper flange from the permanent ring magnet and the lower flange with the steel cylinder (core). We again clamp the basket with the upper flange in a vice and, using a hammer and a tool, knock the flange out of the basket.

We don’t need a basket, but a permanent ring magnet, an upper flange and a lower one with a core will be useful for making a homemade product.

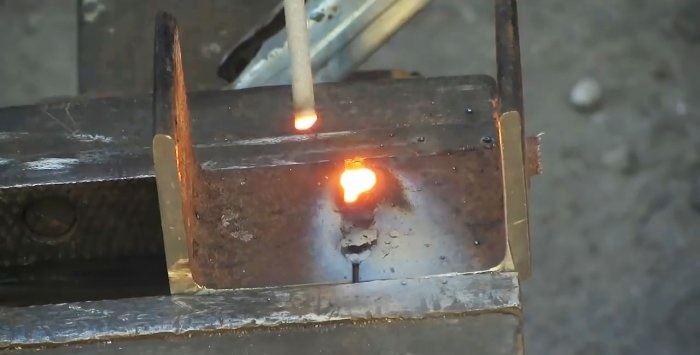

We clamp the lower flange in a vice and use a grinder to cut off the core at the very base.

Next, we turn the part over, punch it in the center and drill a hole, lubricating and cooling the working area, respectively, with oil and water. We cover the surface of the lower flange from the side of the rest of the core and the ring magnet with glue and place the flange with the tip down on the magnet and, after centering, fix them.

From a steel equal angle angle of suitable size, we cut two fragments about 35 mm long.

We connect them with shelves and clamp them in this position in a vice, and weld the joint inside and out.

We sand the top seam with a grinder. We weld an elongated hex nut vertically in the center of the joint of the corners, screwing a bolt into it from above to secure the nut when welding it.

We sand the seam using a grinder. We unscrew the auxiliary bolt from the nut welded to the corners.

We clamp the structure of two corners and a nut in a vice and drill holes opposite each other on the shelves below, closer to the side, cooling the drilling site with water.

We prepare a metal strip with a characteristic bend that separates the ends of the strip along two vertical planes.

We place it on top and longitudinally to the welding seam of the corners without resting on the elongated nut and weld the handle strip in this position.

We return to the ring magnet with a flange and a nut glued from below to the core extension. We screw in a bolt with a washer and a nut from the front side of the flange.

We place an elongated hex nut on top of the bolt head and weld it in this position.

We weld the same nut, but with a smaller diameter, to the stud screwed into the elongated nut on the head of the bolt.

Assemblies consisting of two welded corners, an extended nut and a shaped handle, as well as a permanent magnet, a flange, a bolt with a nut and a washer, and an extended nut welded to the bolt head are painted with black spray paint from a can.

We place the first knot on the grinder so that the holes in the flanges of the corners coincide with the holes on the angle grinder, and the handle of the knot is directed along the body of the tool from above.

We fix the assembly on the angle grinder with bolts on both sides, and fasten the handle to the body with a clamp. Tighten all fasteners with a Phillips and flathead screwdriver.

We screw a pin into the elongated nut of the permanent magnet unit, at the end of which a nut of smaller diameter is welded.

Then we screw the pin into the nut until it appears on the other side. Continuing to rotate further, we screw the free end of the stud into the extended nut of the second assembly.

We screw a threaded handle into the nut at the end of the rod. This operation essentially completed the manufacture and installation of a homemade product on an angle grinder.

Test in practice

By rotating the assembly with a permanent magnet around the stud, you can increase or decrease the distance between the center of the nut (axis of rotation) and the grinder disk.

It will be equal to the radius of the circle that we are going to cut out in sheet metal, if the assembly with the magnet is installed in the center of the circle being cut out, and the grinder with the disk is moved by the handle along a given radius, pressing the tool against the metal.

After the circle is cut, turn off the grinder and lift the circle together with the angle grinder by holding it with the force of a permanent magnet of a homemade device.

The device can be detached from the angle grinder at any time and stored in a drawer until the next need.

If, by the way, your disk is tightly jammed, then there is a very simple way to unscrew the angle grinder nut - https://home.washerhouse.com/en/4301-legkiy-sposob-otkrutit-gayku-bolgarki.html

Watch the video

Similar master classes

An easy way to make a square hole in sheet metal

How to increase the functionality of an angle grinder with removable equipment

How to make a hex hole in metal

Universal brake pad bearing remover

How to easily make a precise cut in a pipe

If your Dremel breaks, it doesn’t matter: a grinder can replace it

Particularly interesting

Comments (4)