3 ways to cut a profile pipe straight

Most amateur craftsmen do not have a miter saw, so they cut the profile pipe using a grinder. This is an imprecise tool and often produces uneven cuts, especially if there is no angle available to mark the cut line. However, you can also cut smoothly with a grinder if you use one of the three proposed methods.

Method 1: Draw under paper

You can draw a straight line for cutting a profile pipe or any pipe using a sheet of paper. The main thing is that it has at least one flat side. The paper is applied with a straight edge to the cut mark on the profile and wrapped around it. When coiling, the sheet is aligned so that its straight side meets along the entire pipe. After this, a line is drawn with a marker under the paper, like a ruler, along which a cut is made.

This method is convenient for cutting large pipes from 100 mm. It also works on a small profile, but with multiple markings, cutting takes a lot of time.

Method 2: Mark using tape measure

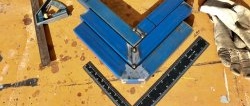

The second method of marking the pipe is suitable if one of its ends is even.To mark, take a tape measure, cling to the straight end, and measure the required length of the profile using it. Using its scale, a mark is made on the pipe, first at one edge, then at the second. The marked points are connected into a line with a marker. The opposite side of the pipe is marked in the same way.

Next, a grinder is used to cut the pipe along one line, then the profile is turned over and a cut is made along the opposite line. Afterwards it is laid on its side and cut by eye, guided by the protruding cuts on the edges of the pipe. If the profile is wide, then you can immediately outline all 4 sides and connect the points under a ruler so as not to distort the cut, especially on the last two sidewalls.

Method 3: Trim by eye in one pass

The fastest way is to trim by eye in one pass. At the same time, with experience, you can gain sufficient skills so that the quality of the end is quite suitable for further welding work.

The cutting disc of the grinder is applied to the pipe from above as perpendicularly as possible. With a developed eye, this will work out the first time. After cutting the upper side of the profile, you need to move the disk to the near side. The tool must also run perpendicular to the pipe. Having two intersecting cuts, all that remains is to deepen the disk, and it will cut the profile to the end without distortion on the remaining walls.

Watch the video

Similar master classes

Particularly interesting

Comments (0)