How to make a jig for absolutely straight cutting with a jigsaw

Due to the small width of the file, an electric jigsaw is considered convenient for sawing along curved trajectories and, for the same reason, of little use for straight cuts. If you don't use the guides, it starts to move to the side. But by equipping the tool with a basic device, you can avoid the above disadvantage. To make it, you only need the simplest materials and some carpentry skills.

Will need

Materials:- electric jigsaw;

- one laminate board;

- highly effective adhesive-sealant and superglue;

- a metal sheet;

- round small neodymium magnets -

The process of making a fixture to ensure a completely straight cut

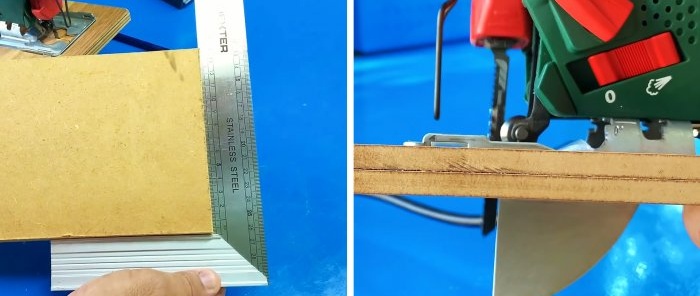

We install the jigsaw sole transversely along the edge of the laminate board, leaving a narrow strip outside.At the same distance from the other edge of the sole, draw a transverse line and cut off the marked fragment of the board, removing the lock.

Using the resulting laminate fragment, we cut another one of the same width.

Place the sole unscrewed from the jigsaw body onto one of the laminate fragments, trace it around the perimeter with a marker and cut it out.

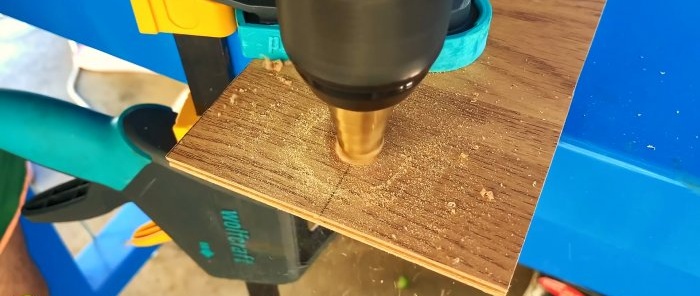

We place the resulting frame on the second fragment, and place the sole of the jigsaw in the recess. We mark the longitudinal line of symmetry of the sole on a solid fragment and the position of the central protrusion. At the mark of the central protrusion, we drill a through hole and make a slot from it deep into the solid fragment.

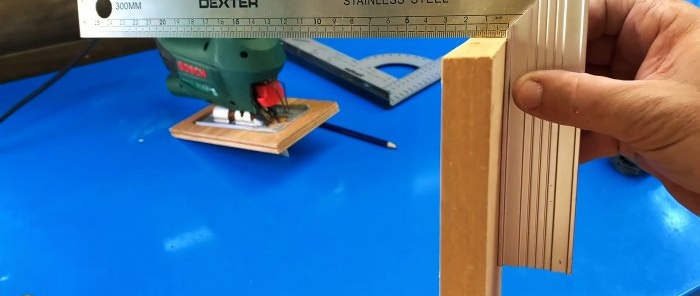

Using highly effective glue, we glue the frame to the second fragment and, securing it around the perimeter with clamps, leave the structure until the glue hardens. We grind the perimeter of the double fragments on an emery machine.

We insert the sole, screwed to the jigsaw, into the recess and mark the location of the back of the file from below. We measure the distance from the blind end of the cut to the location of the file and its reach.

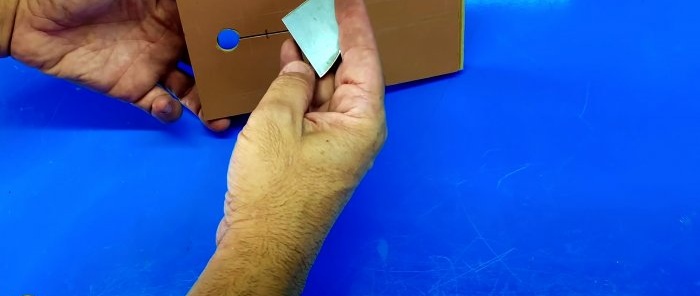

We cut out a quadrant from a metal sheet, the radii of which correspond to the distance from the blind end of the cut to the location of the file, reduced by 1-1.5 mm.

In the bottom of the cutout for the jigsaw sole, along the side with the large hole, we mark and drill four small blind holes and two more on the other side. Using highly effective glue, we attach neodymium magnets to them.

We insert a quadrant with one radius into the slot of the laminate base from below and secure it with superglue.

We insert the “native” sole into the recess of the sole made of laminate.

At the same time, when cutting material with a saw, a metal quadrant located behind it in the cut ensures straightness of the cut, preventing the tool from moving to the side.

And this can be clearly seen during test cuts.

Watch the video

Similar master classes