3 ways to weld a profile at right angles

For each structure constructed from square pipes, it is necessary to use its own connection at an angle of 90 degrees. In some places, simplicity and speed of work performed are important, and in others, reliability and durability are important.

Three ways to connect square pipes at 90 degree angles

I propose to consider three different ways to connect a profile at right angles, for different needs from simple to complex.

First way

This is the easiest way to connect at right angles. To do this, the pipes are simply butt welded to each other. The edges are pre-cleaned.

This method has the main advantage of simplicity and is mainly suitable for quickly constructed structures for a short time.

Although it has more disadvantages than advantages: the edges of the pipes must be perfectly smooth, otherwise there is no need to talk about 90 degrees. Further, the end of one pipe remains open and exposed to weather conditions.

Second way

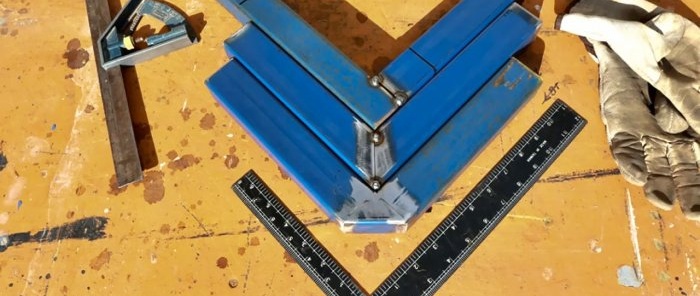

The second and most common method is to weld both pipes at 45 degrees.

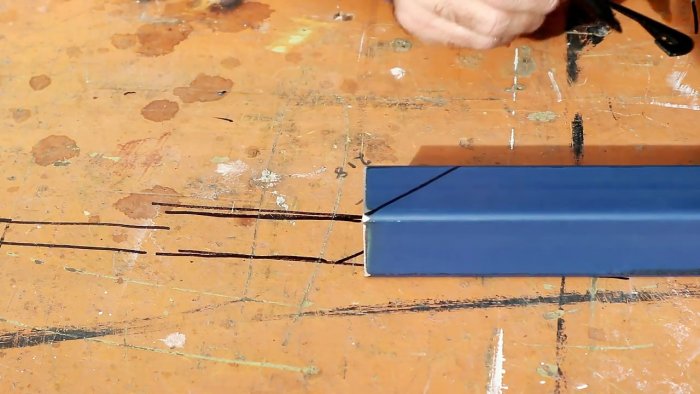

On each pipe, using a marking triangle, we draw cut lines at an angle of 45 degrees.

We connect the bevels.

Next, everything is sawed off with a grinder.

The edges are cleaned.

Before making a continuous seam, we place fixing points.

Next, scald. This method is the optimal and most reliable of all. It is good to use in the manufacture of single, load-bearing structures.

Among the shortcomings, I would like to note the complexity of all calculations and adjustments in precise units.

Third way

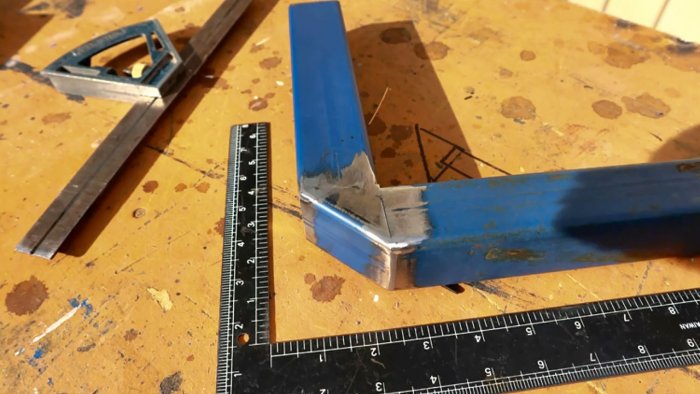

Let's move on to the last and most difficult, at first glance, connection of pipes at 90 degrees: welding with an insert.

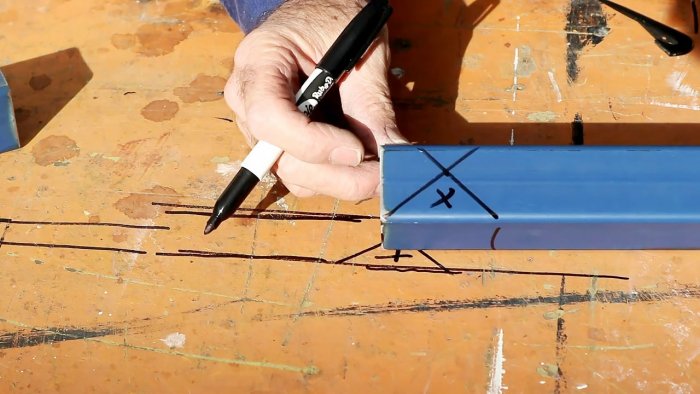

First, an insert must be made from a pipe of the same diameter as the pipes being welded. To do this, draw a line on the profile at 45 degrees.

We lean the pipe and measure its length along the segment.

Then draw a line from this point at a right angle.

It is necessary to cut out the resulting corner.

We clean it up.

The result is a perfect connection.

This method is good for the production of complex structures with a large number of angles. It is enough to cut the required number of these inserts and start assembling.

This connection also has a smooth angle, there are cases where this is necessary.

Watch the video

Similar master classes

Particularly interesting

Comments (0)