A simple DIY oil filter remover

Replacing the oil filter is often accompanied by difficulty in removing it. It is extremely difficult to unscrew it only by hand. When faced with this problem, you can very quickly make a simple puller that allows you to easily unscrew stuck filters.

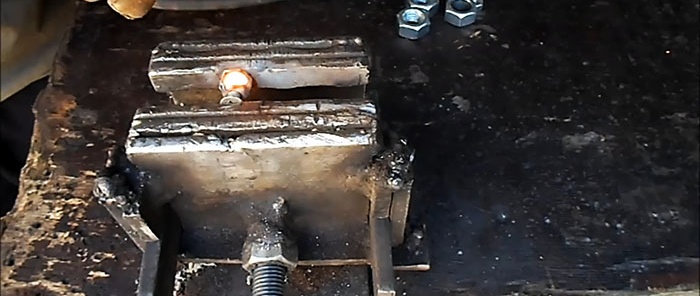

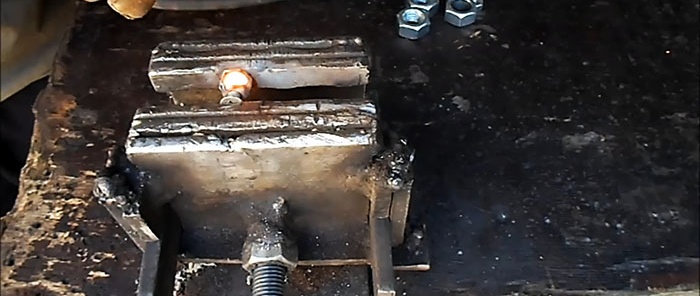

To make a mechanism for fastening the tape, you need to screw an M6 bolt or screw onto a nut, and joining the ends, weld it to the M8 nut. In this case, you need to try not to grab the bolt itself; after welding, it should still rotate. It is required to make 2 sets of such fastenings.

The resulting components are welded on the side to the M14 nut opposite each other.

A small plate is cut from sheet steel to make a stop for the filter. It needs to be bent into a half ring, maybe angular. Holes are drilled along the edges of the plate and bored with a file to a rectangular shape for a perforated strip. This is the most labor-intensive process in the manufacture of a puller.To make it easier, it is better to initially cut a plate from thin steel 2 mm. In its center, between the holes, on the side of the outer bend, an M16 nut is welded.

Then take a piece of perforated tape, in most cases 40 cm will be enough, and thread it through the holes of the thrust plate.

2 M14 nuts are screwed onto the edge of the stud and clamped together. Then a nut with welded ears is screwed onto the stud to the middle. The remaining end of the stud is connected through an M16 nut to the thrust plate, and the ends of the perforated tape passed through it are screwed to the ears with M6 bolts.

By rotating the pin in one direction or another and holding the thrust plate, you can slide the perforated tape out and in. By adjusting it to the desired diameter and placing it on the filter, the loop is tightened. This can be done by hand or with wrenches. Since the ears are in the way on one nut, only an open-end wrench or an adjustable wrench can grab it. The fixed puller is then used as a lever. Having torn off the stuck filter, the tool is removed, and then everything can be easily unscrewed by hand.

Due to the fact that the perforated tape is not welded, but secured with bolts, it can be replaced with a longer one. This will be needed when removing a large filter, for example, on a truck or tractor.

Materials:

- M14 pin;

- nut M16;

- M14 nuts – 3 pcs.;

- M6 nuts – 2 pcs.;

- M8 nuts – 2 pcs.;

- M6 bolts – 2 pcs.;

- perforated mounting tape;

- Sheet steel.

Making a puller

To make a mechanism for fastening the tape, you need to screw an M6 bolt or screw onto a nut, and joining the ends, weld it to the M8 nut. In this case, you need to try not to grab the bolt itself; after welding, it should still rotate. It is required to make 2 sets of such fastenings.

The resulting components are welded on the side to the M14 nut opposite each other.

A small plate is cut from sheet steel to make a stop for the filter. It needs to be bent into a half ring, maybe angular. Holes are drilled along the edges of the plate and bored with a file to a rectangular shape for a perforated strip. This is the most labor-intensive process in the manufacture of a puller.To make it easier, it is better to initially cut a plate from thin steel 2 mm. In its center, between the holes, on the side of the outer bend, an M16 nut is welded.

Then take a piece of perforated tape, in most cases 40 cm will be enough, and thread it through the holes of the thrust plate.

2 M14 nuts are screwed onto the edge of the stud and clamped together. Then a nut with welded ears is screwed onto the stud to the middle. The remaining end of the stud is connected through an M16 nut to the thrust plate, and the ends of the perforated tape passed through it are screwed to the ears with M6 bolts.

By rotating the pin in one direction or another and holding the thrust plate, you can slide the perforated tape out and in. By adjusting it to the desired diameter and placing it on the filter, the loop is tightened. This can be done by hand or with wrenches. Since the ears are in the way on one nut, only an open-end wrench or an adjustable wrench can grab it. The fixed puller is then used as a lever. Having torn off the stuck filter, the tool is removed, and then everything can be easily unscrewed by hand.

Due to the fact that the perforated tape is not welded, but secured with bolts, it can be replaced with a longer one. This will be needed when removing a large filter, for example, on a truck or tractor.

Watch the video

Similar master classes

Particularly interesting

Comments (6)